Method for realizing light amplification of optical waveguide device using up-conversion luminescent material

A technology of luminescent materials and optical waveguides, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of easy aging of devices and high cost of pump light sources, and achieve the effects of signal light gain, low price, and small optical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

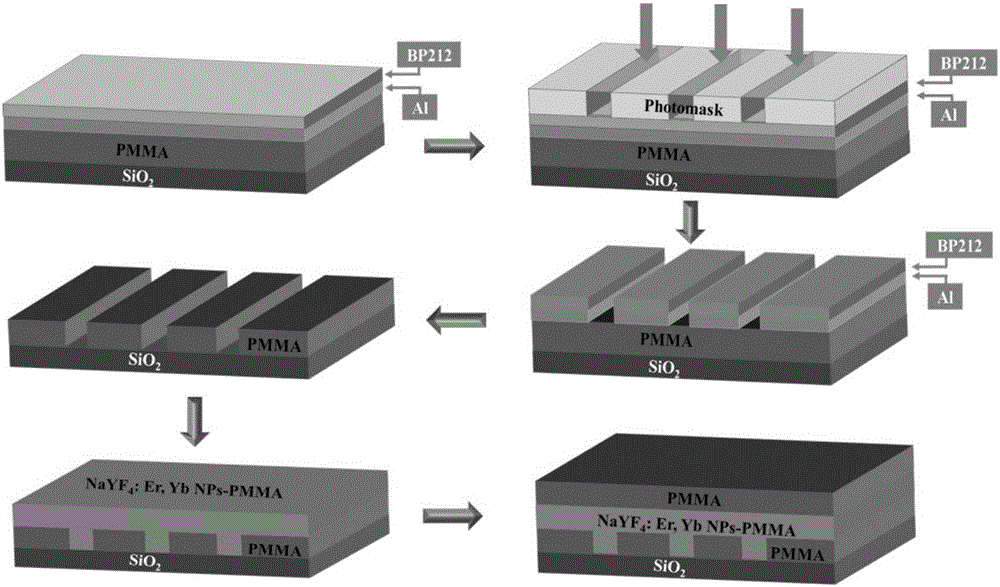

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of red upconversion luminescent core-shell KMnF by solvothermal method 3 :18mol%Yb 3+ ,1mol%Er 3+ QUR 3 :2mol%Yb 3+ nanomaterials. QUR 3 :18mol%Yb 3+ ,1mol%Er 3+ Preparation of nuclei: Take 10mL oleic acid and 5mL ethanol, put them into a 50mL flask, take 12mmol KOH and add them into 5mL deionized water, mix and dissolve fully, add the solution into the flask, and stir well at room temperature. Weigh MnCl 2 (0.324mmol), YbCl 3 (0.072mmol),ErCl 3 (0.004mmol) and KF (3.5mmol) solids were added to the flask and stirred to dissolve, and vigorous stirring was continued for half an hour. Finally, the mixed solution was transferred to a 30 mL polytetrafluoroethylene-lined autoclave, sealed, and heated in an oven at 200° C. for 1 hour. down to room temperature to obtain KMnF 3 nuclear nanoparticles. Measure 10mL of oleic acid and 5mL of ethanol into a 50mL flask, add 12mmol of KOH into 5mL of deionized water, mix and dissolve fully, add the solution...

Embodiment 2

[0052] (1) Preparation of green upconversion luminescent core-shell α-NaYF by heterogeneous core induction by solvothermal method 4 / β-NaLuF 4 : Yb, Er nanoparticles. The sensitizer ion Yb in the shell 3+ The molar doping amount is 18%, and the luminescent center ion is Er 3+ , a molar doping concentration of 2%. Measure 20mL oleic acid, 10mL ethanol and 2mL deionized water and stir to mix. Weigh 0.6g of NaOH solid into the mixed solution, stir until fully dissolved, and obtain a clear solution A. Weigh 0.5mmol of YCl 3 ·6H 2 O solid, dissolved in 4 mL deionized water. This solution was added dropwise into mixed solution A, and stirred vigorously for half an hour to obtain solution B. Weigh 2mmolKF·2H 2 O solid, fully dissolved in 4mL of deionized water, was added dropwise into solution B, and continued to stir for half an hour. Finally, the mixed solution was evenly transferred to two 30mL Teflon-lined high-pressure reactors, sealed, and heated in an oven at 160°C f...

Embodiment 3

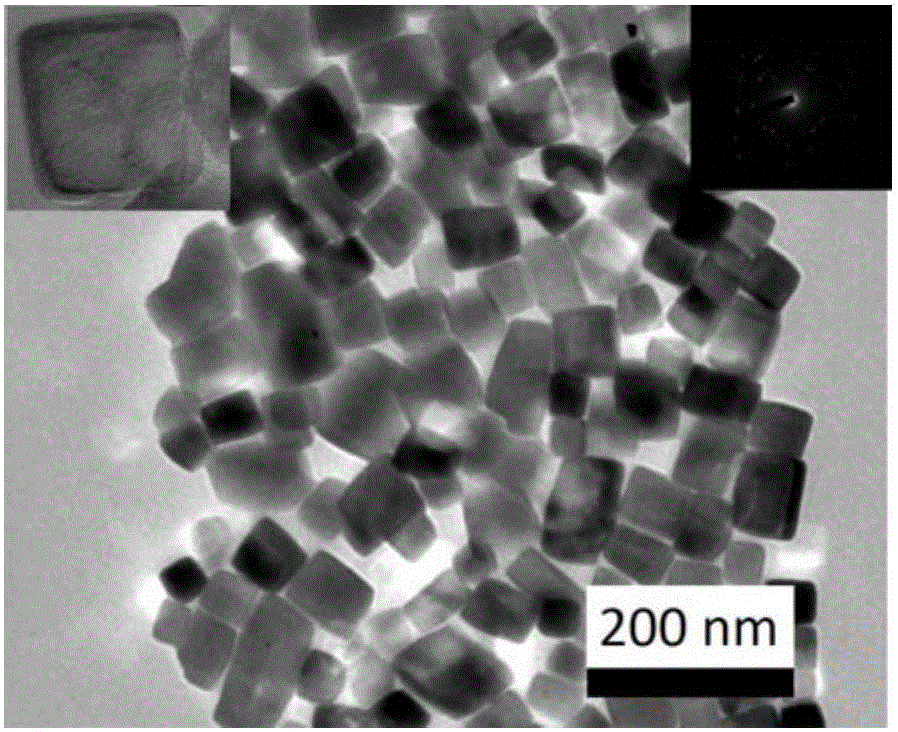

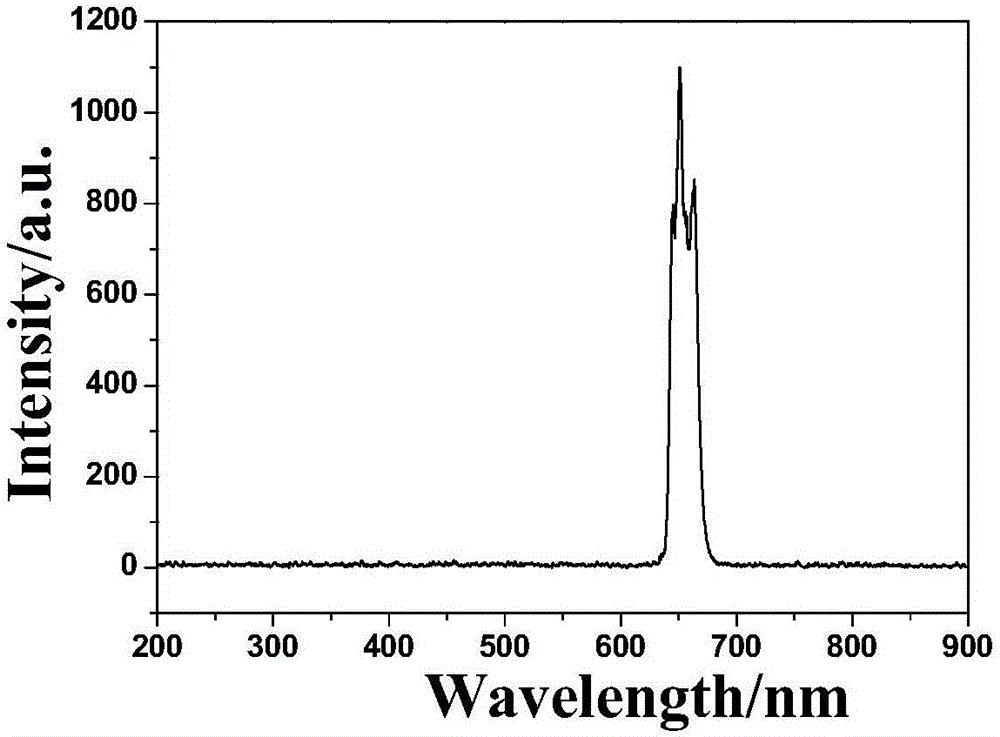

[0056] (1) Preparation of NaYF by solvothermal method 4 : Yb, Er nanoparticles. Weigh 0.5 g of polyvinylpyrrolidone (PVP), add 10 mL of ethylene glycol, stir until dissolved, and obtain a clear solution A. Weigh 1mmol (0.058g) NaCl 3 Solid and stoichiometric YCl 3 ·6H 2 O, YbCl 3 ·6H 2 O, ErCl 3 ·6H 2 A total of 0.25 mmol of O (mole weight Y:Yb:Er=80:18:2) was dissolved in 2 mL of water, added to solution A, stirred until fully dissolved, and mixed solution B was obtained. Weigh 5mmol (0.47g) KF·2H 2 O solid, fully dissolved in 8mL ethylene glycol solution, then added dropwise into solution B, and stirred vigorously for half an hour. Finally, the mixed solution was transferred to a 30 mL polytetrafluoroethylene-lined autoclave, sealed, and heated in an oven at 180 °C for 2 hours to obtain NaYF 4 : Yb, Er nanoparticles. Figure 11 Water (alcohol) soluble NaYF prepared by solvothermal method 4 The transmission electron micrograph of :Yb:Er nanoparticles, the average ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com