Operation method of main punching device of integrated full-automatic device for punching and cutting metal plates

A fully automated equipment and metal sheet technology, applied in the field of blanking devices, can solve problems such as large labor resources and scattered processes, and achieve the effects of reducing costs, improving production efficiency, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

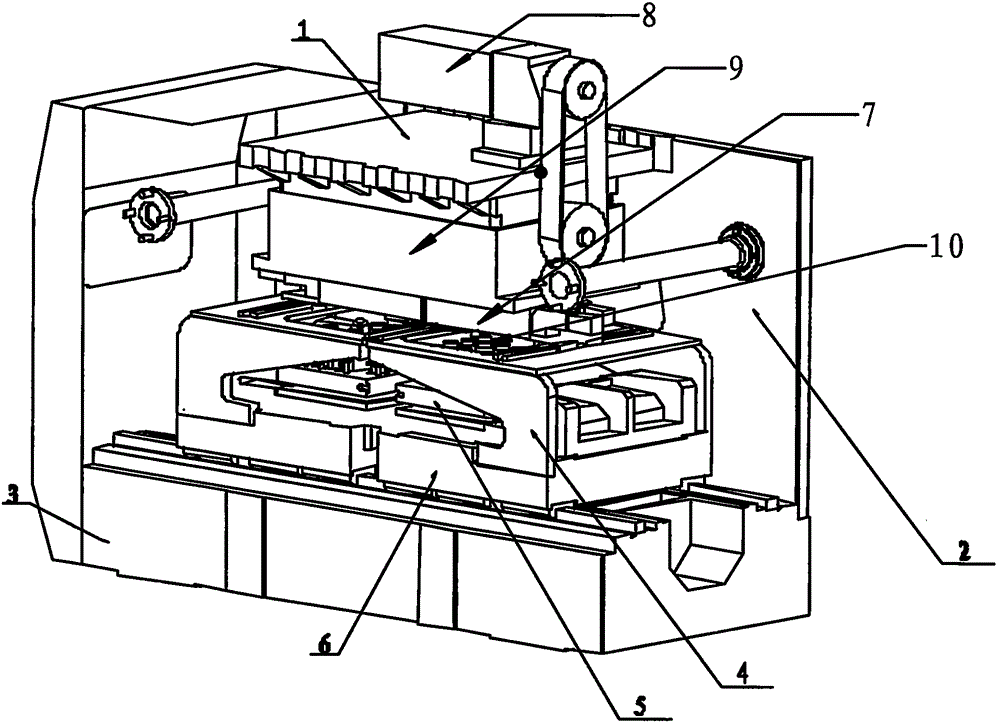

[0020] The punching main machine is installed horizontally, the main base 3 is set under the punching main machine, the main frame 2 is arranged on the symmetrical sides of the main base 3, and the upper side of the main frame 2 is symmetrically reserved. 1. A servo motor 8 is set above, and a mold striking plate 9 is set below the hitting table 1. A timing belt is set between the mold striking plate 9 and the servo motor 8;

[0021] Two mold bases 6 are symmetrically arranged above the main base 3, and a transverse guide rail is arranged between the mold base 6 and the main base 3; grooves are reserved symmetrically on the outer edge of each mold base 6, and a striking head pallet frame 4 is arranged in the grooves, and the mold The mold storehouse 5 is arranged on the seat 6, and the middle part of the mold storehouse 5 is reserved for a material inlet and outlet, and the main chassis frame 2 is reserved for an inlet and outlet for the material outlet, and the material outlet...

Embodiment 2

[0024] When processing sheet metal, the plc sends an instruction to the feeding mechanism to send the sheet metal into the material inlet and outlet; at the same time, the mold seat 6 drives the striking head pallet frame 4 above it, the mold library 5, and the striking seat 7 to adjust the integrated machine Lateral position, pause at the right time.

Embodiment 3

[0026] At the same time, the vertical adjustment of the striking seat 7 and the horizontal adjustment of the striking head, the striking head stops when the striking station is set correspondingly, the servo motor 8 drives the mold striking plate 9 to press the striking head downward, and the striking head is aligned with the punch in the mold station 10. Punch the metal sheet into the mold, complete the punching, and enter the second punching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com