Molding method of cooling system of rapid heating die

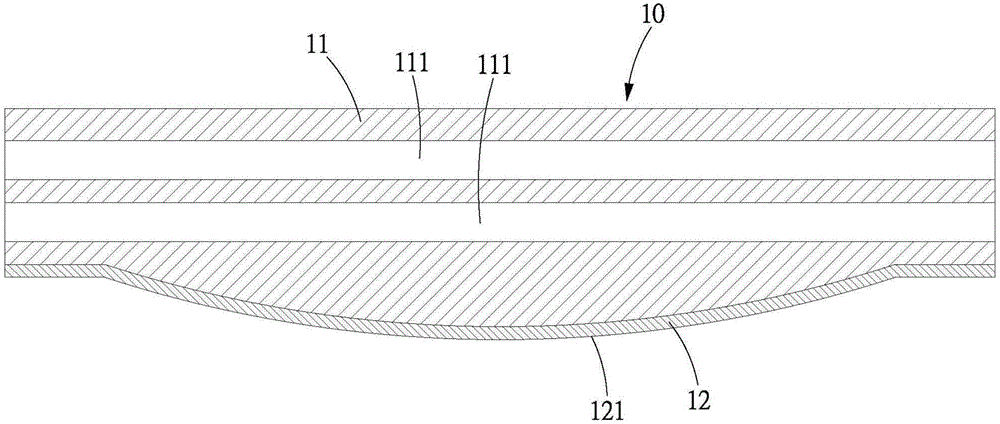

A molding method and cooling system technology, applied in casting molding equipment, cores, molds, etc., can solve the problems of difficult access, difficult processing, and inability to conform to the mold surface 121 of the mold layer 12

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

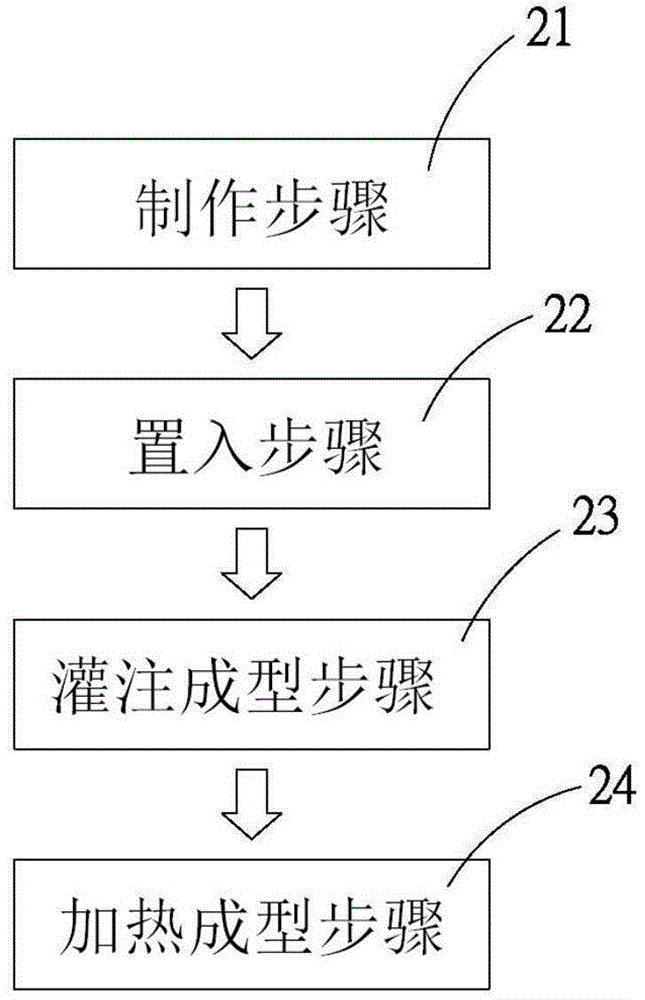

[0087] refer to figure 2 As shown, the cooling system forming method of a rapid heating mold provided by the first embodiment of the present invention is mainly composed of a printing step 21, an inserting step 22, an infusion molding step 23, and a removal molding consisting of step 24, wherein:

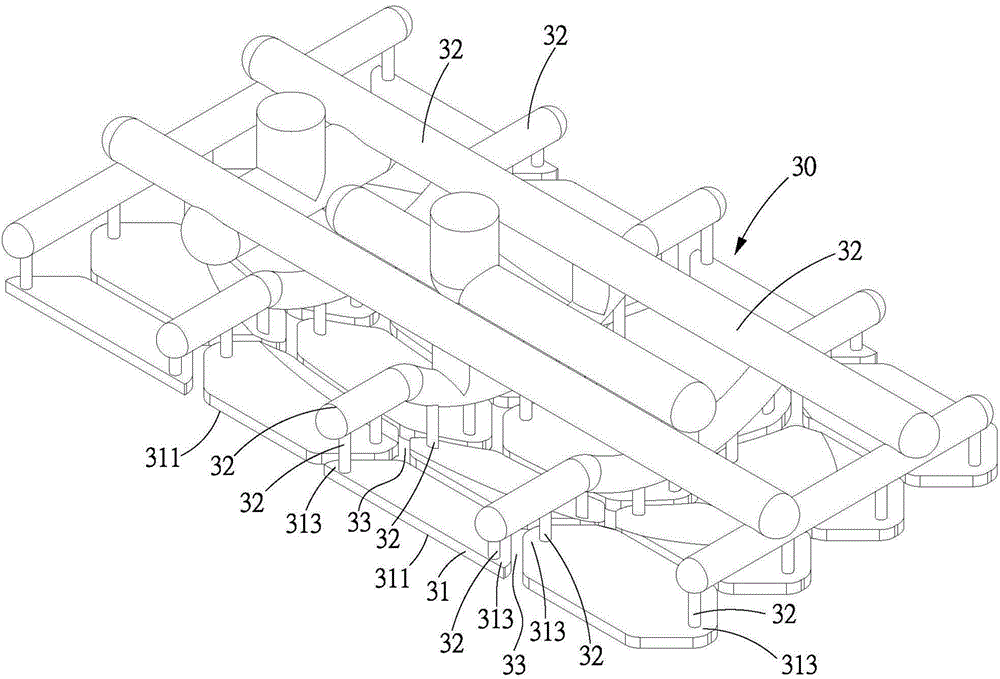

[0088] refer to Figure 3-1 , Figure 3-2 ,and Figure 3-3 As shown, the manufacturing steps are: create a physical cooling waterway object 30 that is the default cooling waterway, and the physical cooling waterway object 30 includes a plurality of bonding parts 31 and a plurality of branch parts 32 connected to each other; in this embodiment, it is The solid cooling waterway object 30 is printed out by 3D printing technology, but not limited thereto. There is a gap 33 between the joint parts 31 of the solid cooling waterway object 30, and each The surface 311 of the bonding portion 31 is on a predetermined shape of a bonding mold surface (not shown in the figure).

[0089] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com