A Welding Method of Chromium-Molybdenum-Vanadium Steel for Ultra-Thickness Pressure Vessels

A technology for pressure vessel and chrome molybdenum vanadium steel, which is used in household vessels, welding equipment, welding/welding/cutting items, etc., can solve the problems of cold crack joints, low welding efficiency, lack of fusion, etc. Simple, ensure the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation cases of the patent of the present invention will be described in detail in conjunction with the accompanying drawings.

[0016] In this implementation case, 12Cr2Mo1VR is used as the base material, the thickness is 210mm, and the way of butt jointing of steel plates with the same thickness is adopted. The following welding measures are adopted for the welding of the chromium molybdenum vanadium steel:

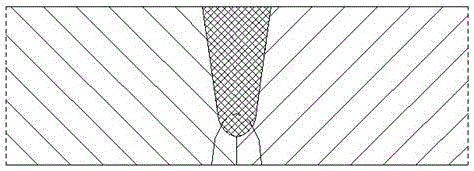

[0017] 1) The groove is processed by mechanical processing method at the butt joint. The groove form is a single-sided U-shaped groove, the blunt edge of the groove is 7-9mm, and the bottom of the groove is a circular arc.

[0018] 2) The two chromium-molybdenum-vanadium steel plates to be welded are butted and fixed by spot welding.

[0019] 3) Submerged arc narrow gap welding: Preheat the workpiece to be welded before welding, the preheating temperature is ≥180°C, and use submerged arc narrow gap welding to perform multi-pass welding from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com