Ironwork feeding mechanism

A technology of iron products and reclaiming mechanism, which is applied in the field of machinery, can solve the problems of jammed feeding direction, low production capacity, easy fatigue and error, etc., and achieve the effect of improving work efficiency, improving work efficiency and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings.

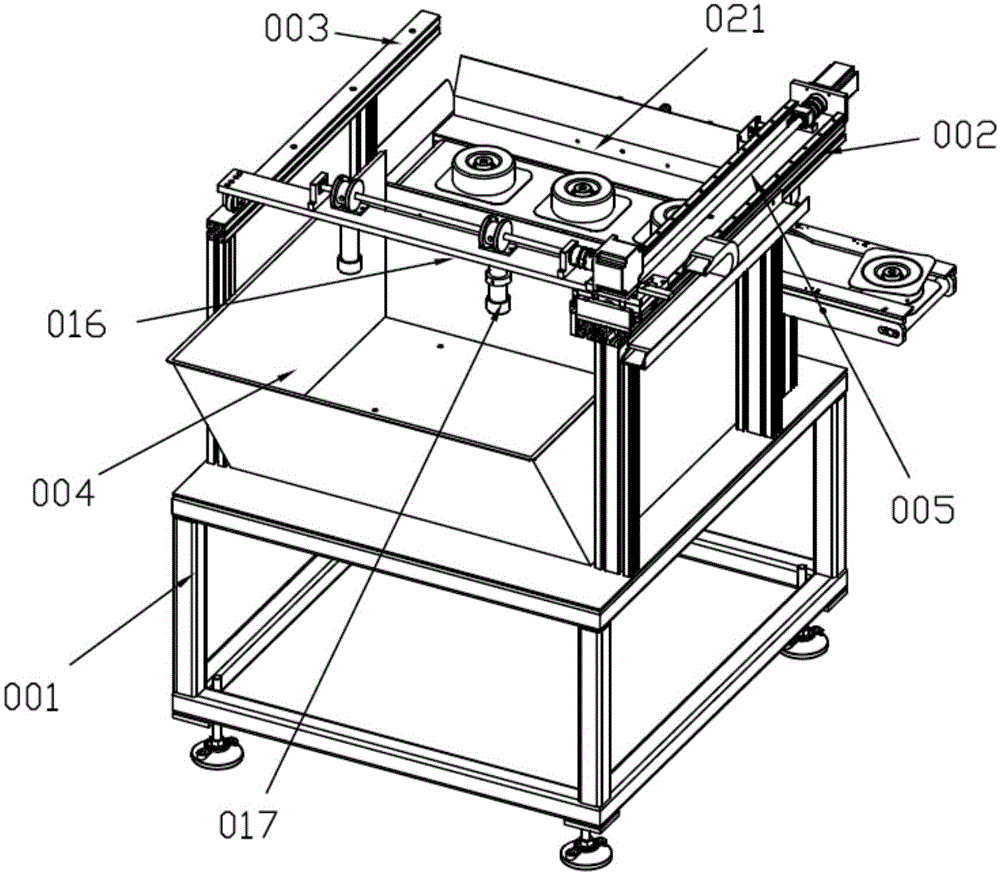

[0019] figure 1 It schematically shows an iron product feeding mechanism according to the present invention.

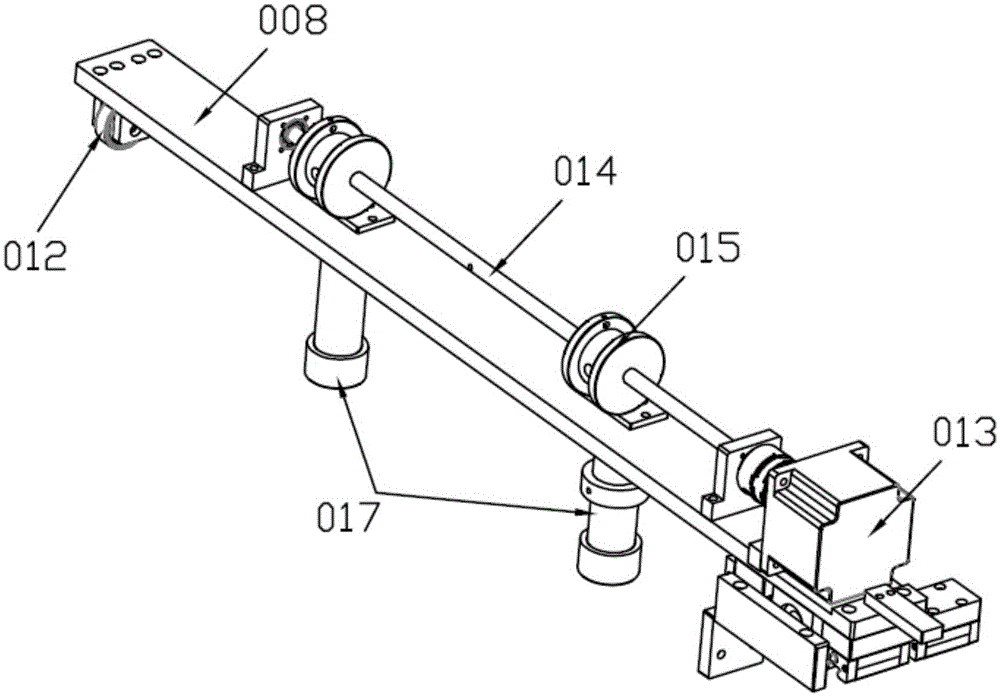

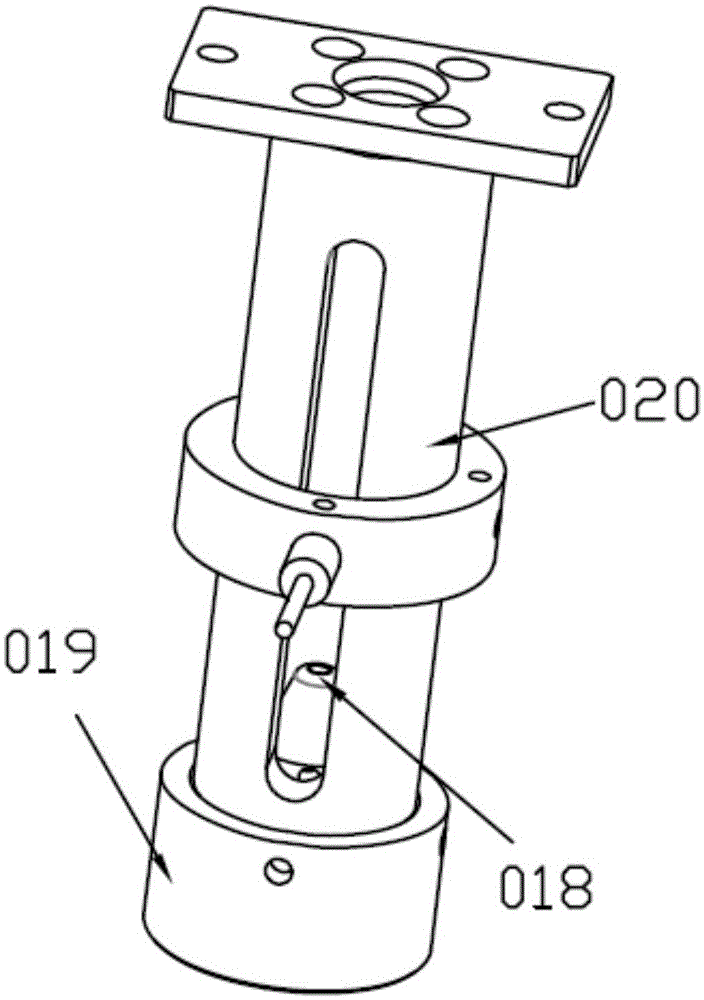

[0020] An iron product feeding mechanism provided in this embodiment, please refer to figure 1 , Including: a loading frame 001, on which a first crossbeam 002 and a second crossbeam 003 are symmetrically arranged, and a lower part between the first crossbeam 002 and the second crossbeam 003 The front and rear servo moving mechanism 005 with a loading frame 004 is connected with a product reclaiming mechanism 016, and a reclaiming magnet suction tool 017 is provided on the product reclaiming mechanism 016, please refer to figure 2 , The product reclaiming mechanism 016 includes a reclaiming seat 008 horizontally arranged on the first cross beam 002 and the second cross beam 003, the reclaiming magnet suction tool 017 is set on the reclaiming seat 008, and the reclaimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com