Trolley for replacement of flip-chip current transformer of centrally installed switchgear

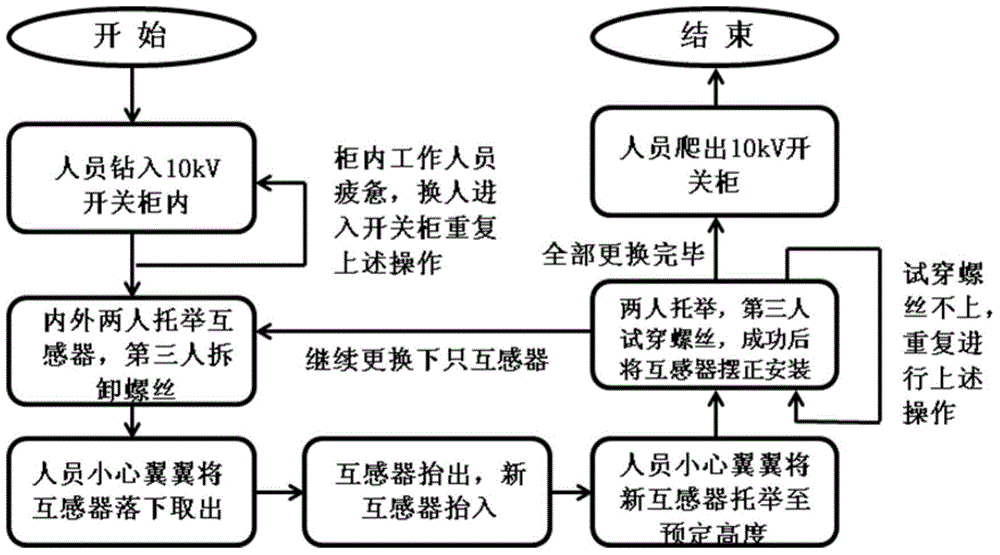

A current transformer and flip-chip technology, which is applied to the field of replacing trolleys for current transformers in central cabinets, can solve the problems of difficult work and labor consumption, and achieve the effects of saving labor costs, reducing operation time, and shortening replacement operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

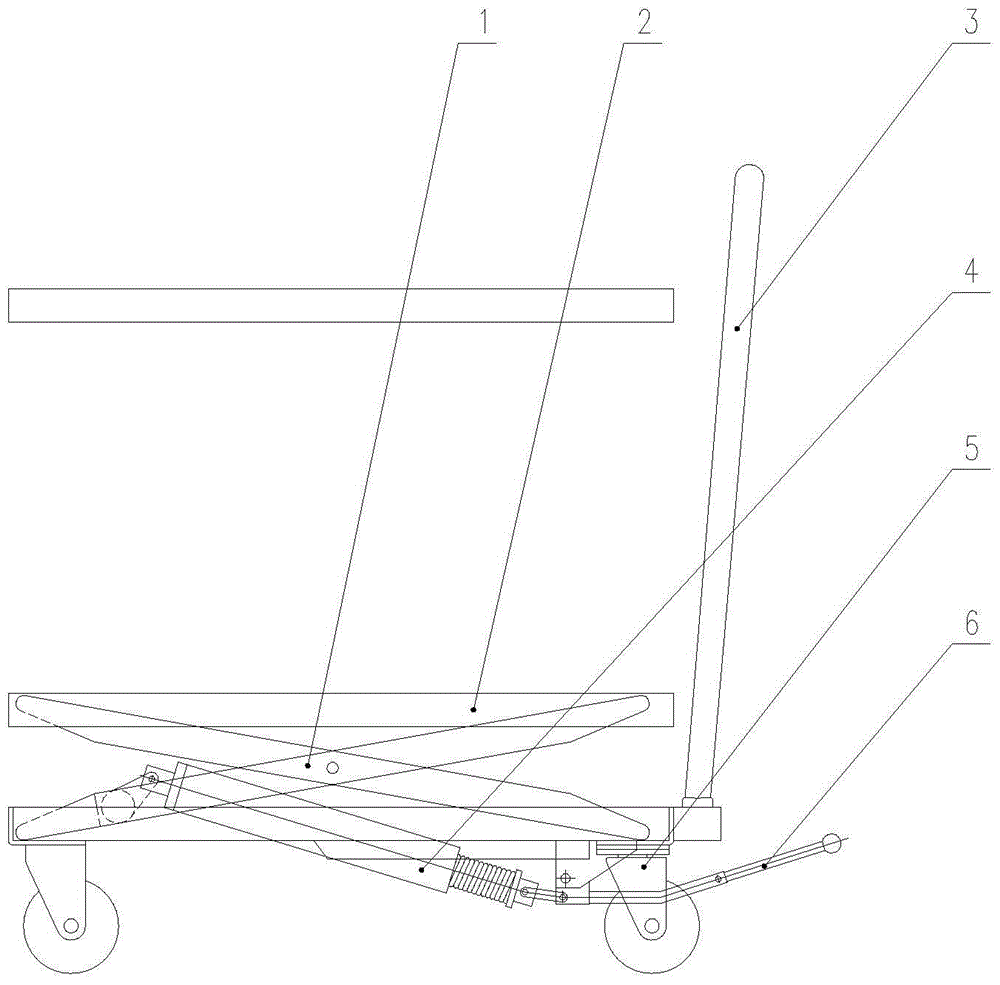

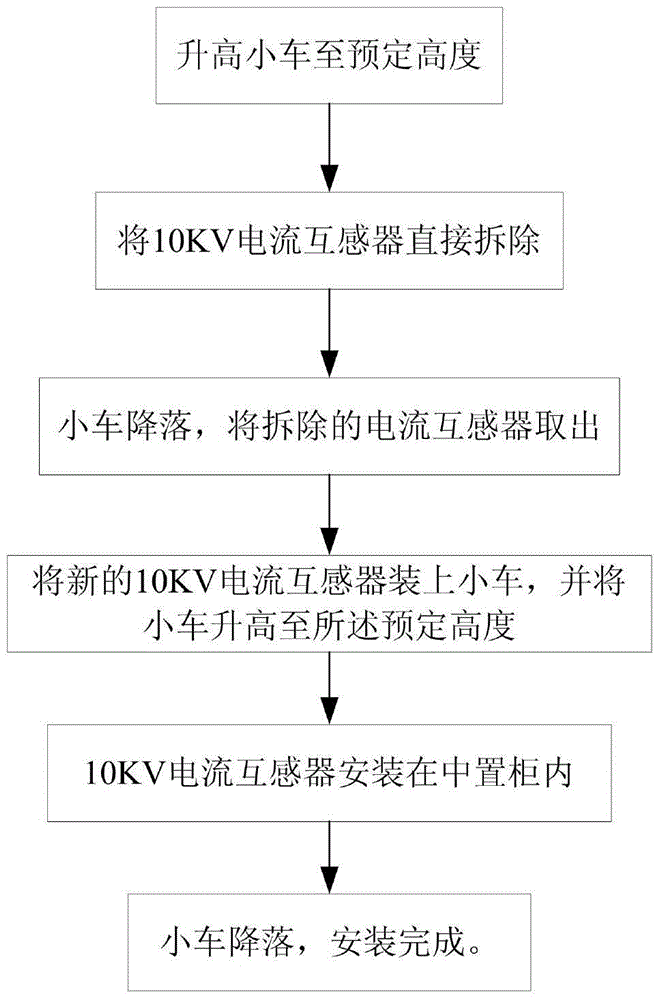

[0021] Specific implementation mode 1. Combination Figure 2 to Figure 4 Description of this embodiment, 1. The trolley for replacing the upside-down current transformer in the middle cabinet is characterized in that it includes fixing the yoke lifting device 1 between the support platform 2 and the base of the trolley, and the yoke lifting device 1 The hydraulic pump 4 fixed on the top, the lifting handle 6 connected with the hydraulic pump 4; the hydraulic pump 4 is operated by the lifting handle 6 to drive the fork arm lifting device 1, and the height of the supporting platform 2 is controlled to realize the inverted installation of the central cabinet. Replacement of current transformers.

[0022] In this embodiment, horizontal guide rails are installed on the lower surface of the support platform and the upper surface of the base. When the hydraulic pump expands and contracts, the yoke lifting device 1 is driven to move on the horizontal guide rails.

[0023] This embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com