Production technology of sterile oxygen humidification bottles

A production process and oxygen humidification technology, which is applied in the field of medical devices, can solve the problems of inability to carry out terminals, plastic packaging materials are not resistant to high temperature, and bacteria, and achieve the effect of solving infection and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

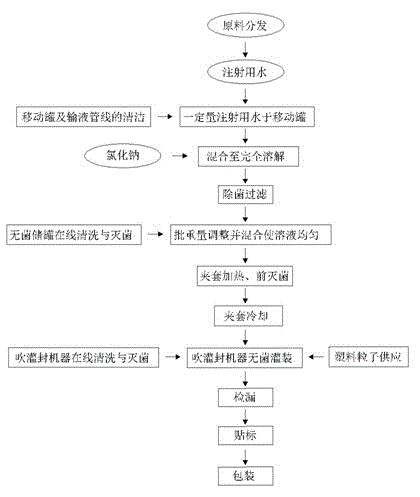

[0018] Such as figure 1 , now in conjunction with the production process flow chart of the present invention, the production process of the aseptic humidification bottle using the humidification solution produced by the present invention as physiological saline is described in detail;

[0019] The implementation environment of the present invention is a clean workshop that meets the requirements of GMP, and the environment level is set to C level, and the blowing, filling and sealing machine is installed under the A level laminar flow of the C level background environment, and all tools and clothing in contact with materials are sterilized Store under laminar flow; before production, personnel should change their clothes as required; production tools and utensils should be sterilized; mobile tanks should be cleaned; aseptic storage tanks, blow-fill-seal machines, and humidification fluid delivery pipelines should be cleaned and sterilized online ; The transportation of the hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com