Domestic wastewater purifying treatment technology

A domestic sewage and purification treatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of no treatment process, reduce burden, improve treatment efficiency, High removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

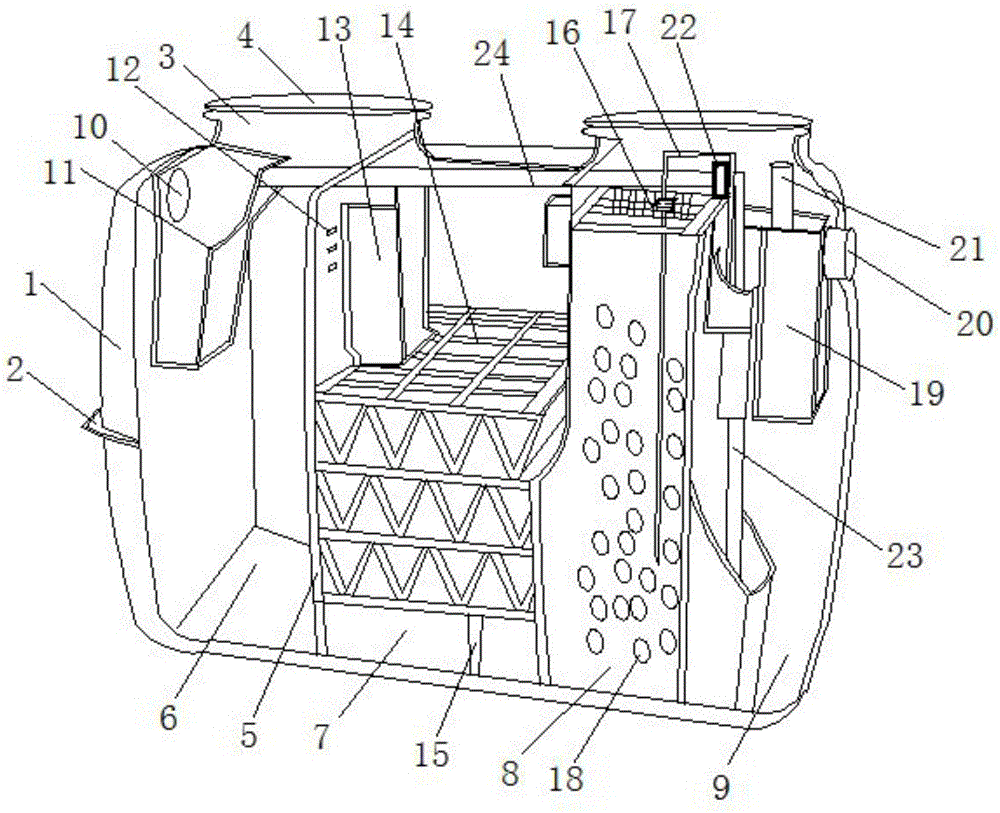

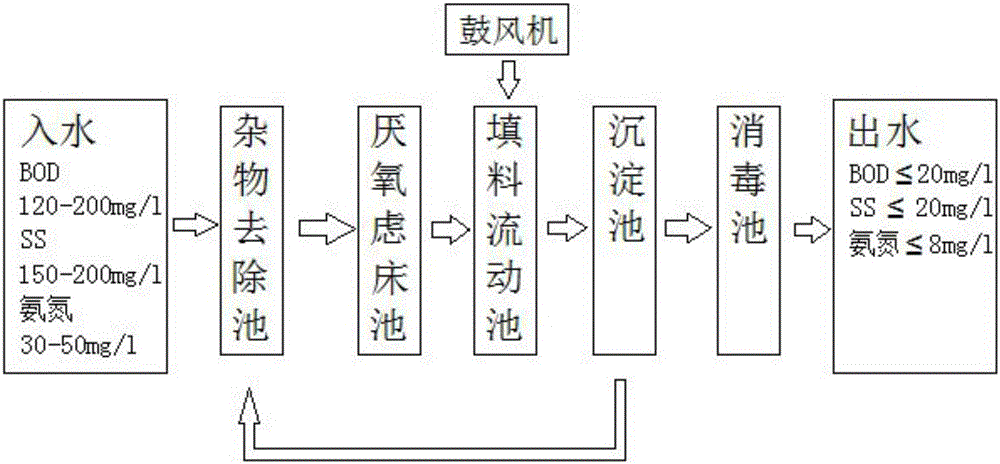

[0018] A domestic sewage purification process, such as figure 2 As shown, the process includes specific steps in the following sequence: pass domestic sewage through the debris removal tank to intercept domestic debris, control the flow rate of sewage at 0.1-0.3 cubic meters per hour, and control the retention time at 30-50min; the intercepted sewage Enter the anaerobic filter bed pool for anaerobic fermentation for 12-24 hours, remove deactivated organic matter after fermentation, control the fermentation temperature at 35-55°C, and control the pH at 5.5-6.5; the sewage after anaerobic fermentation enters the filled flow pool for exposure Gas fermentation, the sewage after aeration and fermentation enters the sedimentation tank for sedimentation for 5-8 hours, the supernatant is sterilized and discharged from the chlorine disinfection tank for recycling, and the lower part of the sediment is in the state of aeration and agitation, and the water pump returns to the sundries re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com