Preparation method of foundation reinforcement material

A foundation reinforcement and additive technology, applied in the field of building materials, can solve the problems of waste of resources, unreasonable utilization of resources, environmental and social hazards, etc., to reduce processing costs, enhance unconfined compressive strength, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

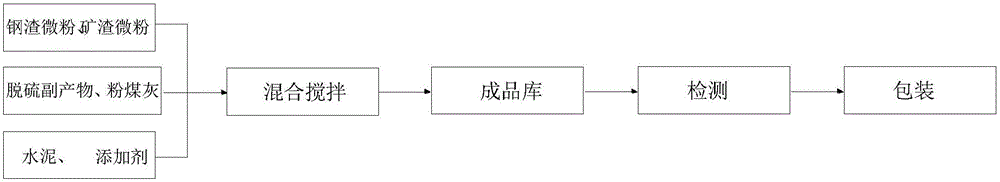

[0026] The above components are fully stirred and mixed evenly, sent to the finished product warehouse, and then packed after passing the test. The process route is shown in Figure 1.

[0027] Performance testing:

[0028] 1. Specimen strength and impermeability test:

[0029] Raw materials: According to the distribution characteristics of the foundation soil of general sites in Shanghai, three typical natural soils were selected and mixed with two cementing materials to process them into reinforced soil. Three typical natural soil types are: the ② layer of brownish-yellow silty clay, the ③1st layer of muddy silty clay and the ③2nd layer of sandy silt.

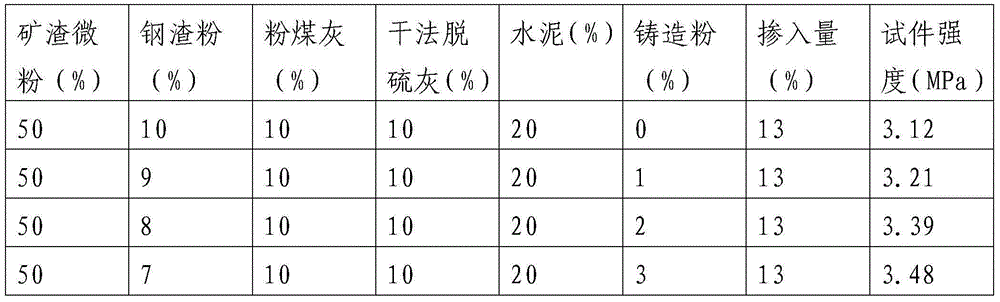

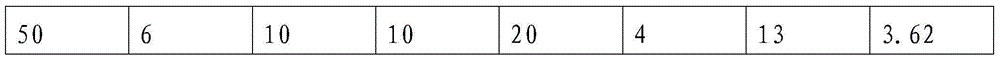

[0030] The two cementing materials are the foundation reinforcement material in this example and P42.5 ordinary silicate cement, the water-cement ratio is 0.45, and the addition amount is 13%.

[0031] Sample preparation: The unconfined compressive strength sample is prepared by using a split test mold with an in...

Embodiment 2

[0055]

[0056] The above components are fully stirred and mixed evenly, sent to the finished product warehouse, and then packed after passing the test. The process route is shown in Figure 1.

[0057] Test: The soil foundation reinforcement material (B#) and 42.5 grade ordinary silicon cement (A#) in this example are used in the construction technology of three-axis mixing piles, the mixing amount is 20%, the water-cement ratio is 1.5, and the sinking speed is 0.5 , the lifting speed is 1.0, the flow rate is 327, and the test age is 28 days. The structural strength of A# and B# mixing piles is shown in the following table:

[0058]

[0059]

[0060] It can be seen from the table that the structural strength of the mixing pile using soil foundation reinforcement materials is obviously higher than that of the mixing pile using 42.5 grade ordinary silicon cement, and the strength of the 20% cemented powder mixing pile is 20% The strength of ordinary silicon cement-soil mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com