Method of extracting starch from waste tobacco leaves

A technology for discarding tobacco leaves and starch, applied in the field of starch extraction, can solve the problems of low content and low industrial feasibility, and achieve the effects of increasing content, improving utilization value and increasing extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

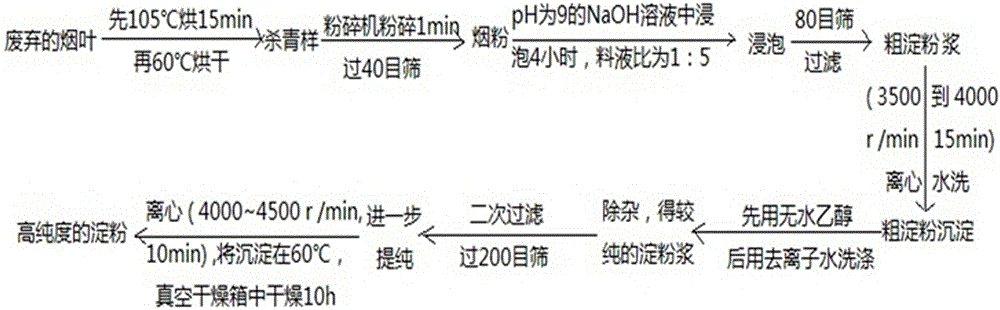

Image

Examples

Embodiment 1

[0024] The method for extracting the starch in the waste tobacco leaf of the present embodiment, the steps are as follows:

[0025] (1) Prepare finished samples: put the tobacco leaves in an oven, adjust the temperature of the oven to 105°C and continue drying for 15 minutes, then lower the temperature of the oven to 60°C, and dry the tobacco leaves;

[0026] (2) Preparation of tobacco powder: Add the dried and finished sample into a pulverizer to pulverize for 1 minute, pass through a 40-mesh sieve, and weigh 100g of processed tobacco powder;

[0027] (3) Soaking: put the smoke powder into NaOH solution with pH 9 and soak for 4 hours, the mass ratio of smoke powder to NaOH is 1:5;

[0028] (4) Filtration: pass the soaked tobacco powder slurry through an 80-mesh sieve, and the under-sieve is the required coarse starch slurry;

[0029] (5) Centrifugation: Centrifuge the coarse starch slurry (3500~4000r / min, 15min), filter the supernatant, and wash the precipitate with water re...

Embodiment 2

[0034] The method for extracting the starch in the waste tobacco leaf of the present embodiment, the steps are as follows:

[0035] (1) Prepare finished samples: put the tobacco leaves evenly on the comb-type tobacco clips and put them in an oven, and bake them at 100°C for 20 minutes, in order to inactivate the enzymes in the tobacco leaves in a short time, and then lower the temperature Tobacco leaves are dried at 55°C to obtain finished samples;

[0036] (2) Preparation of smoke powder: put the finished sample into the pulverizer and pulverize it for 3 minutes, pass through a 40-mesh sieve to obtain smoke powder;

[0037] (3) Soaking: Put the tobacco powder in NaOH solution with a pH of 8 and soak for 6 hours to obtain the tobacco powder slurry. The mass ratio of tobacco powder to NaOH solution is 1:2. The main function is to inhibit the enzymatic hydrolysis of starch in the tobacco powder , enhance the solubility of protein, and improve the whiteness of its starch at the ...

Embodiment 3

[0044] The method for extracting the starch in the waste tobacco leaf of the present embodiment, the steps are as follows:

[0045] (1) Prepare finished samples: put the tobacco leaves evenly on the comb-type tobacco clips and put them in an oven, and bake them at 110°C for 10 minutes, in order to inactivate the enzymes in the tobacco leaves in a short time, and then lower the temperature Tobacco leaves are dried at 65°C to obtain finished samples;

[0046] (2) Preparation of tobacco powder: put the finished sample into a pulverizer and pulverize it for 1 minute, pass through a 40-mesh sieve to obtain smoke powder;

[0047] (3) Soaking: Put the smoke powder into NaOH solution with a pH of 12 and soak for 2 hours to obtain a smoke powder slurry. The mass ratio of smoke powder to NaOH solution is 1:9. The main function is to inhibit the enzymatic hydrolysis of starch in the smoke powder , enhance the solubility of protein, and improve the whiteness of its starch at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com