A kind of rubber material with high hardness and low compression set and preparation method thereof

A permanent deformation and rubber material technology, which is applied in the field of rubber, can solve the problems of high hardness and low compression permanent deformation rubber materials, such as unsatisfactory effects, inability to continue production, and complex processes, etc., to achieve broad industrialization and market prospects, taking into account processing technology and Performance requirements, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

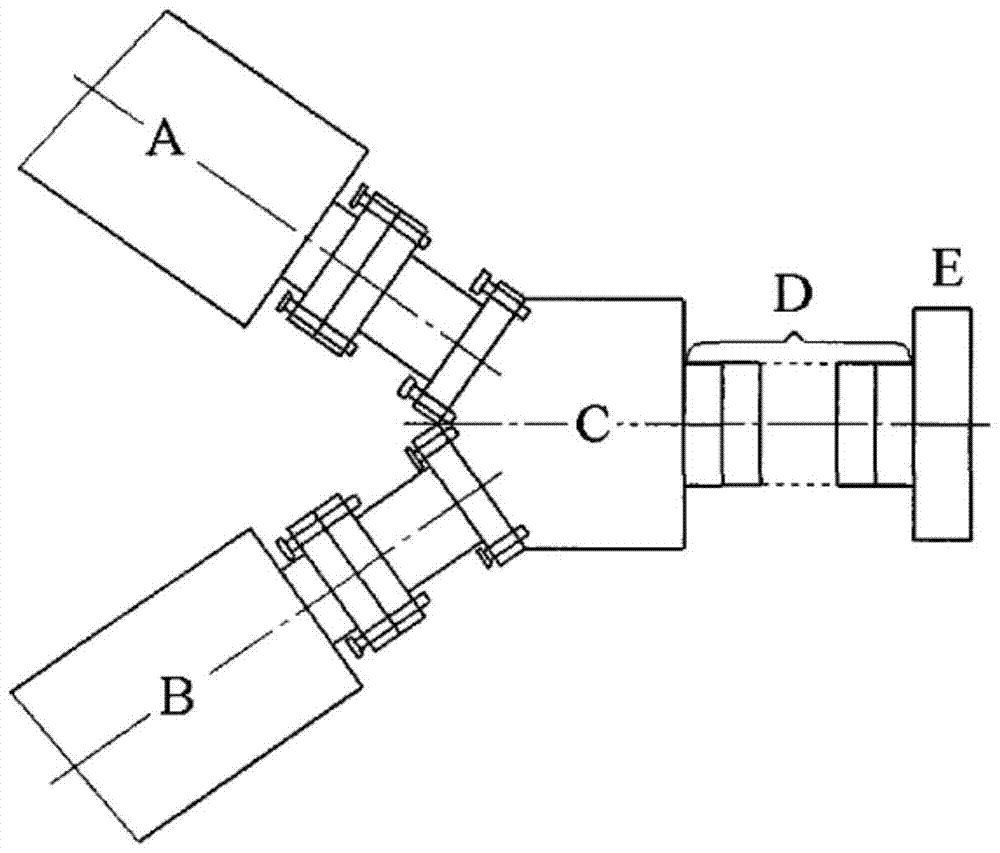

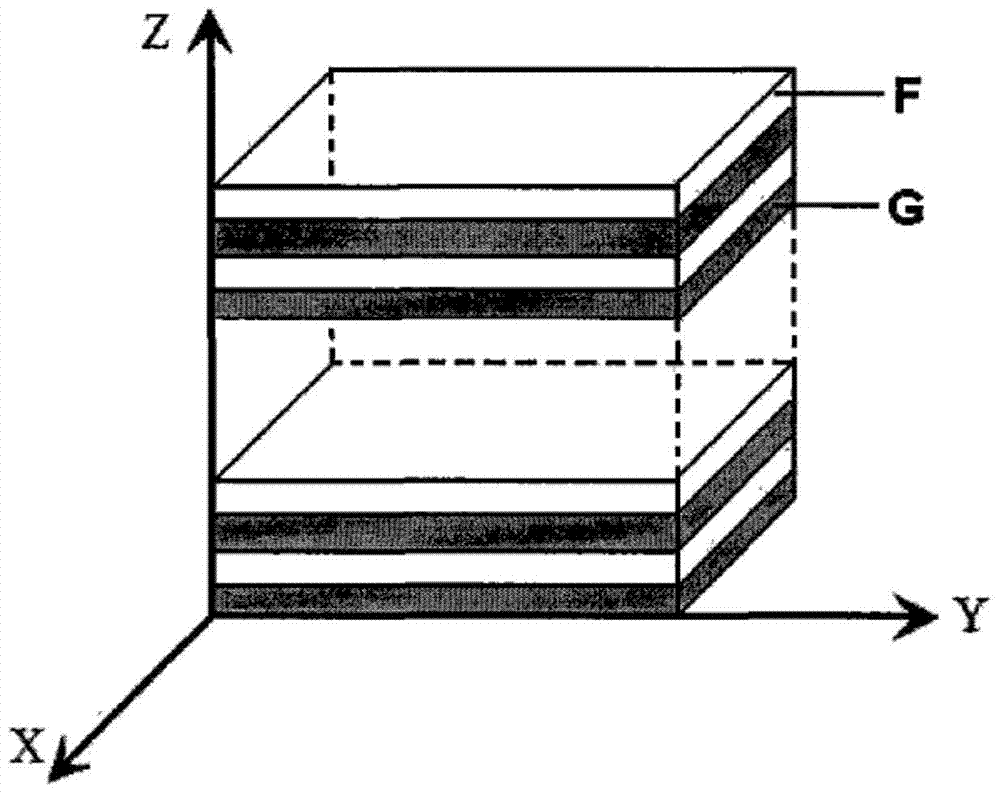

Method used

Image

Examples

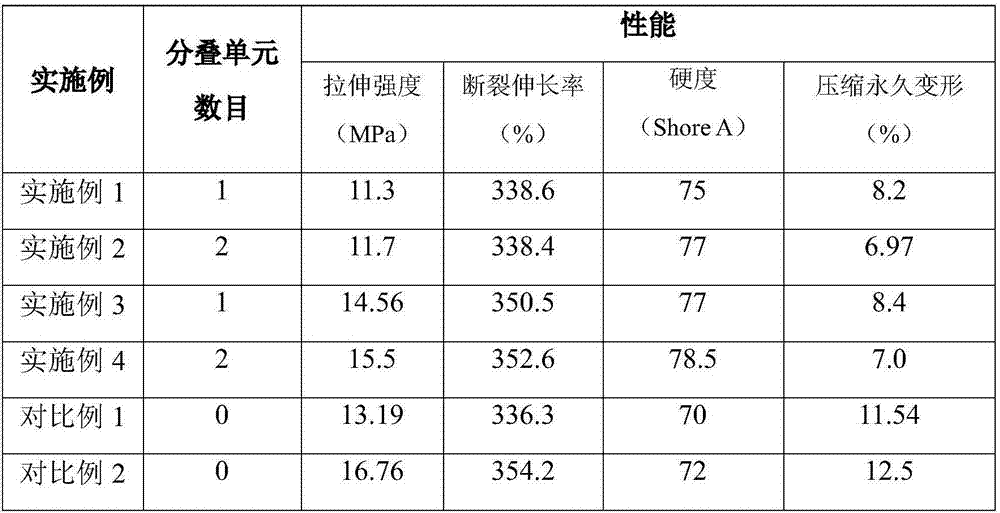

Embodiment 1

[0050] (1) Select 100 parts of EPDM rubber (Keltan2650) as the matrix of the rubber soft layer, add 60 parts of carbon black N990 (filler), 3 parts of bis-tert-butyl peroxide dicumylbenzene (vulcanizing agent), three parts Allyl isocyanurate (curing aid) 1 part, zinc oxide (activator) 5 parts, stearic acid (processing aid) 0.5 parts, 2,2,4-trimethyl-1,2- 2 parts of dihydroquinoline polymer (anti-aging agent), 1 part of 2-mercaptobenzimidazole (anti-aging agent), knead on a double-roll mill at 80 ° C for 15 to 20 minutes to produce a rubber soft layer compound Rubber mixing. The Shore A hardness of the mixed rubber after vulcanization was 68, and the compression set was 4.8 (125°C×22h, 25%).

[0051] (2) Select 100 parts of EPDM rubber of the same brand as the matrix of the rubber hard layer, add 60 parts of carbon black N550 (filler), 60 parts of silicon powder (filler), bis-tert-butyl peroxide diisopropylbenzene (vulcanizing agent) 3 parts, triallyl isocyanurate (curing aid...

Embodiment 2

[0054] The one stacked unit in step (3) in Example 1 was changed to two stacked units to obtain 8 layers of soft and hard alternating multilayer structure rubber material, and the corresponding test results are shown in Table 1.

Embodiment 3

[0058] (1) Select 100 parts of EPDM rubber (Keltan2650) with a higher double bond content as the matrix of the rubber soft layer, add 60 parts of carbon black N990 (filler), bis-tert-butyl peroxide diisopropylbenzene (sulfurized agent) 3 parts, triallyl isocyanurate (co-curing agent) 1 part, zinc oxide (activator) 5 parts, stearic acid (processing aid) 0.5 parts, 2,2,4-trimethyl 2 parts of 1,2-dihydroquinoline polymer (anti-aging agent), 1 part of 2-mercaptobenzimidazole (anti-aging agent), kneading on a double-roller mill at 80°C for 15 to 20 minutes to produce a tablet. A rubber soft layer compound is prepared. The Shore A hardness of the mixed rubber after vulcanization was 68, and the compression set was 4.8 (125°C×22h, 25%).

[0059] (2) Select 100 parts of EPDM rubber (Keltan2470) with higher ethylene content as the matrix of the rubber hard layer, add 60 parts of carbon black N550 (filler), bis-tert-butyl peroxide dicumyl benzene (vulcanizing agent) ) 2 parts, trially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com