Seawater-resistant normal-temperature quickly-cured adhesive

A fast-curing, seawater-resistant technology, used in adhesives, non-polymer adhesive additives, adhesive types, etc., to achieve strong adhesion and mechanical strength, excellent seawater resistance, and improved mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

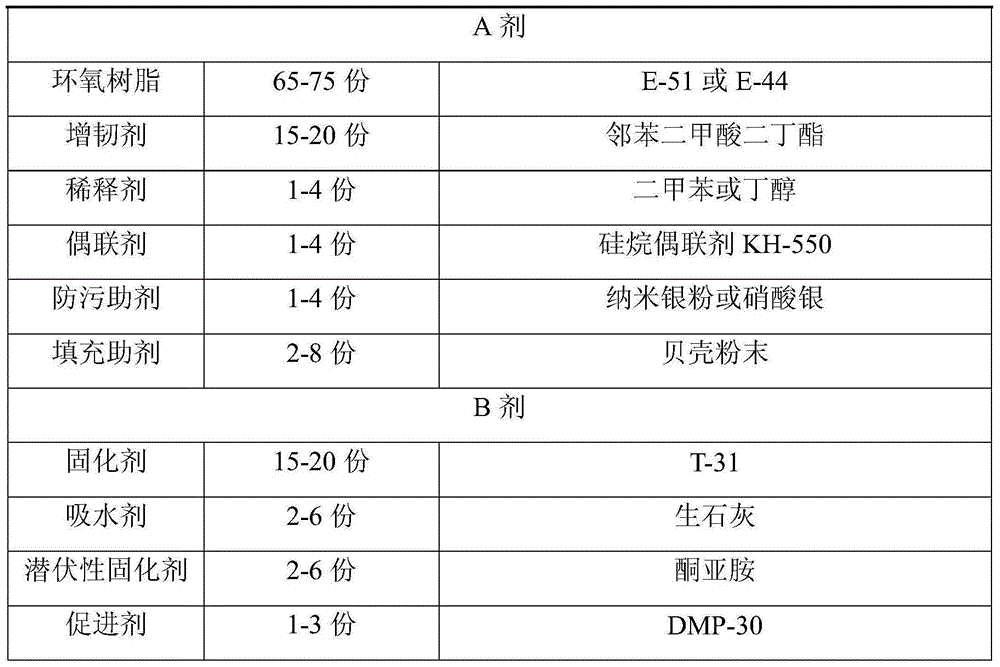

[0024] Combining the characteristics of the required adhesive, the inventor prepared a seawater-resistant fast-curing adhesive that meets the requirements, and successfully solved the problems encountered in the project. The specific implementation method is: according to the weight ratio, 65 parts of E-44 epoxy resin, 18 parts of dibutyl phthalate, 3 parts of butanol, 3 parts of silane coupling agent KH-550, 10 parts of shell powder, Mix it into Agent A; then take 15 parts of T-31, 2 parts of quicklime, 2 parts of ketimine and 2 parts of DMP-30, and mix it into Agent B.

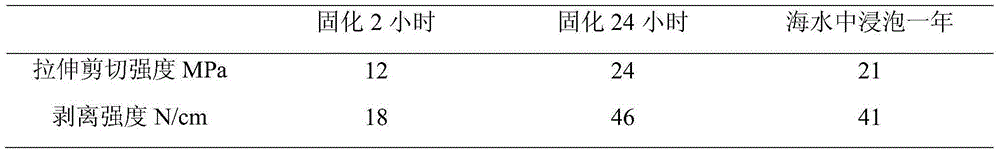

[0025] A and B agents are mixed according to the weight ratio of 5:1, and then the mixed adhesive is applied to the cleaned mussel shell and the surface of the sensor, and then the two can be bonded. It can be initially cured in 10 to 15 minutes, and can reach bonding strength after 2 hours of immersion in seawater. After 12 months of experimental observation, the adhesive can maintain a stable bonding stre...

Embodiment 2

[0032] According to the needs of the actual project, the inventor prepared an adhesive suitable for the instrument according to the following implementation method: according to the weight ratio, get 70 parts of E-51 epoxy resin, 15 parts of dibutyl phthalate, 3 parts of xylene, 3 parts of silane coupling agent KH-550, 2 parts of nano-silver powder and 8 parts of shell powder, mixed into agent A; take 18 parts of T-31, 2 parts of quicklime, 4 parts of ketimine and 2 parts of DMP-30 , and mix it into agent B.

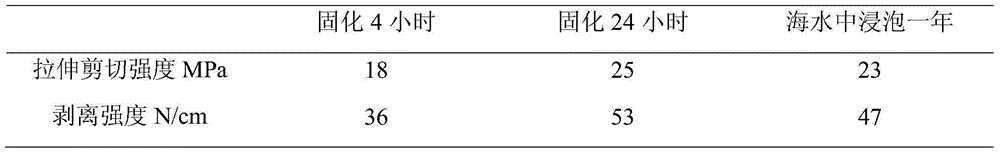

[0033] Mix A and B agents according to the weight ratio of 5:1, and then apply the mixed adhesive evenly on the surface of marine equipment. Under normal circumstances, the required bonding strength can be achieved after 2 hours. If the equipment needs to be soaked in seawater for a long time, in order to ensure the bonding effect, the bonding part should be cured for 4 hours before being put into seawater. After 20 months of experimental observation in seawater, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com