Device and method for purifying CO2 in natural gas by low-temperature pressure swing adsorption process

A technology of pressure swing adsorption and natural gas, which is applied in the direction of chemical instruments and methods, separation methods, gas fuels, etc., to achieve the effects of increasing adsorption capacity, reducing use, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

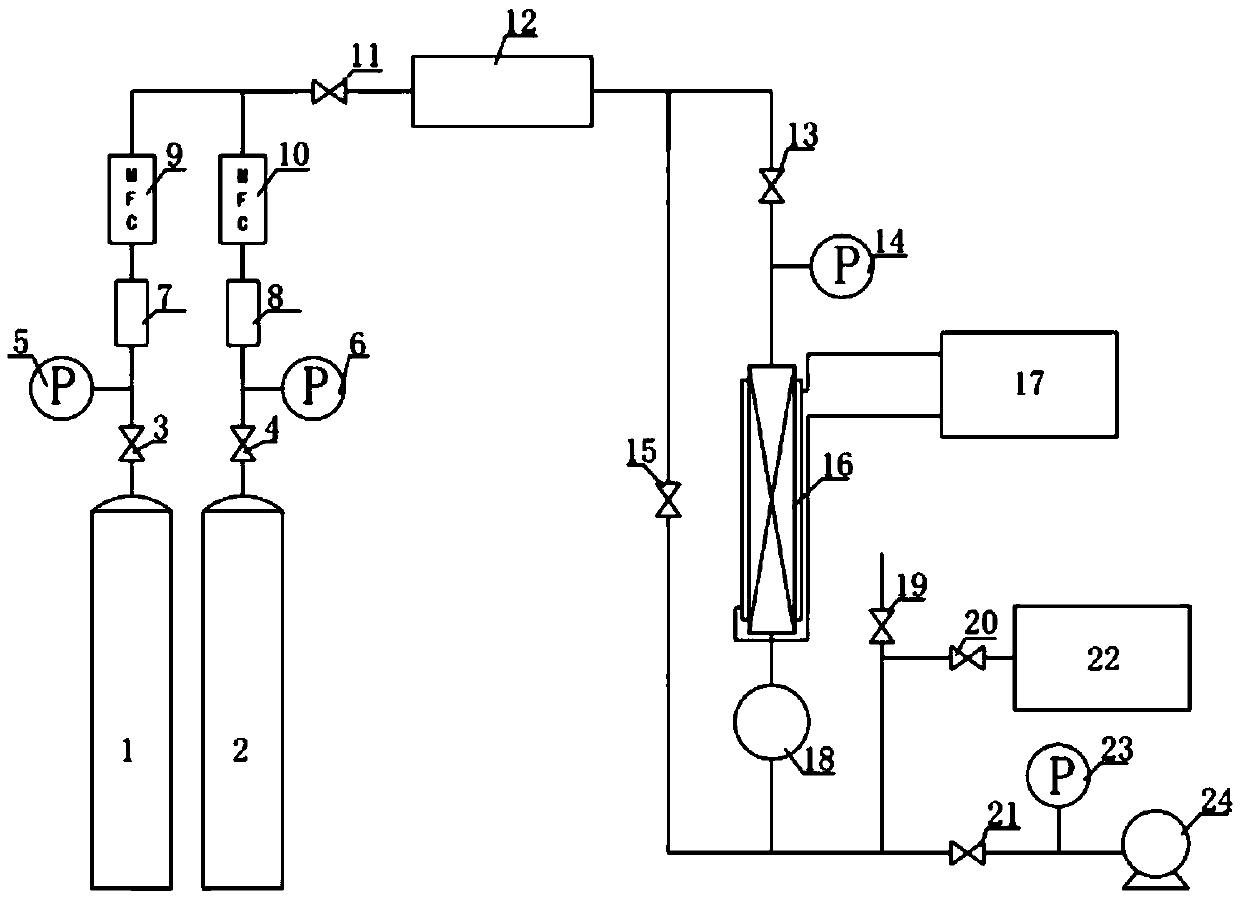

Method used

Image

Examples

Embodiment 1

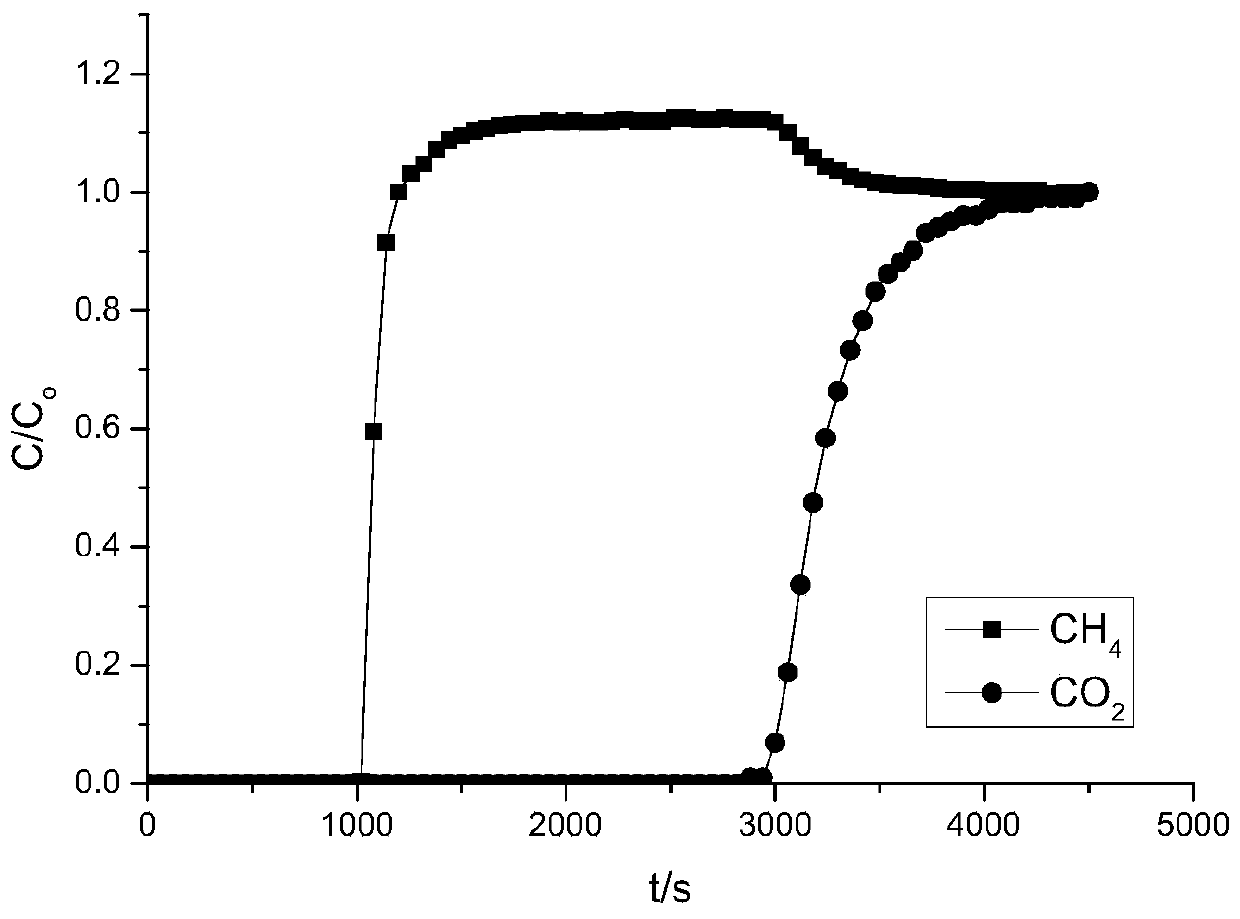

[0041] The pretreated natural gas with a pressure of 1.6MPa is pre-cooled to 0°C, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -10°C. The adsorber has been pre-loaded with coconut shell activated carbon and activated carbon particles. Diameter 1 ~ 3mm, specific surface area greater than 500m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as image 3 shown. CH 4 The breakthrough time is 1840s, CO 2 Breakthrough time is 6120s, CO ...

Embodiment 2

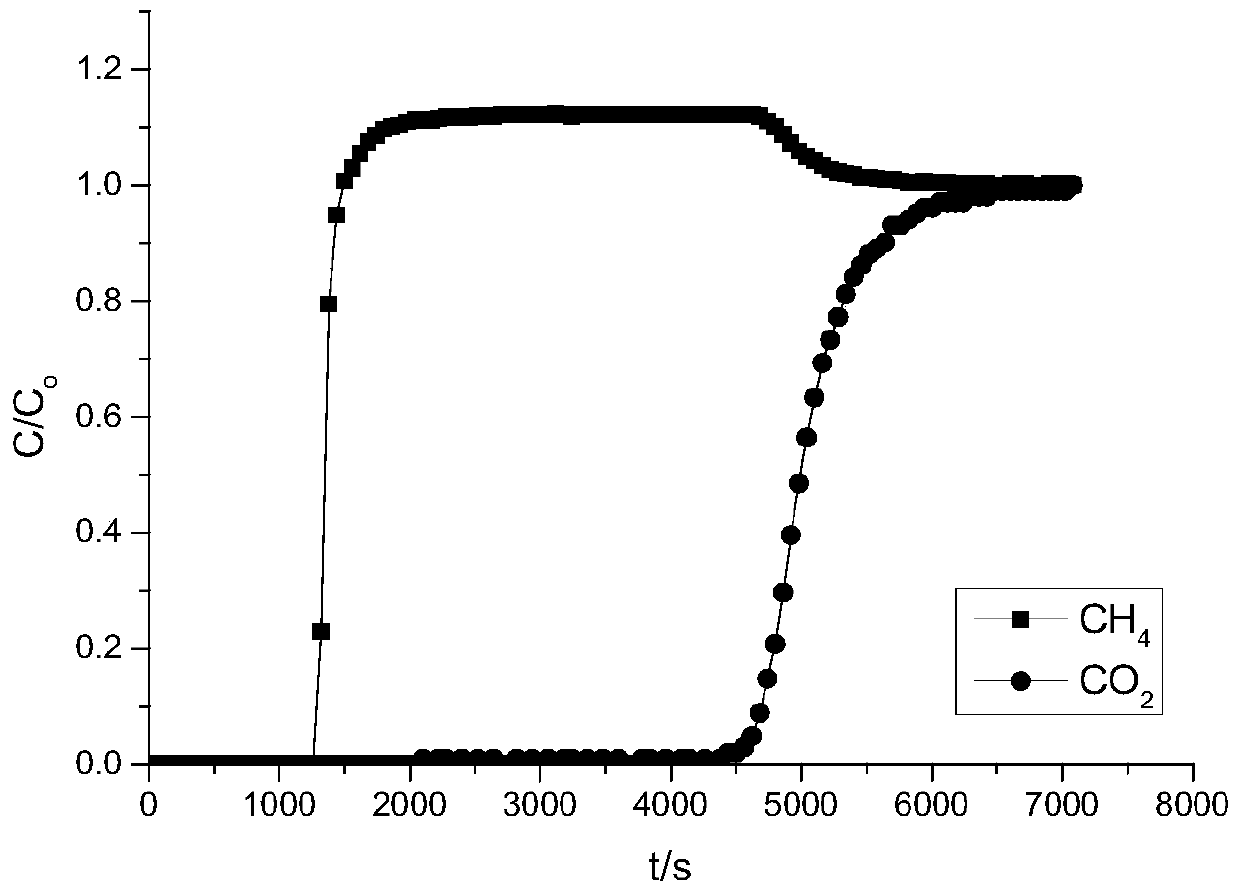

[0043] The pretreated natural gas with a pressure of 3.8MPa is pre-cooled to -10°C, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -20°C. The adsorber has been pre-loaded with 13X molecular sieve, molecular sieve particles Diameter 1.5 ~ 3mm, specific surface area greater than 650m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as Figure 5 shown. CH 4 The breakthrough time is 2240s, CO 2 Breakthrough time is 7210s, CO 2 / CH 4 T...

Embodiment 3

[0045] The pretreated natural gas with a pressure of 6.5MPa is pre-cooled to -10°C in the first stage, and passed into the low-temperature pressure swing adsorption purification natural gas system that has been cooled to -30°C. The adsorber has been pre-loaded with mesoporous material MCM- 41. The particle size of mesoporous materials is 2-4mm, and the specific surface area is greater than 800m 2 / g. At this time, the low-temperature pressure swing adsorption purification natural gas system is in a low-temperature and high-pressure state, and the solid adsorbent will degrade the CO in natural gas. 2 Adsorbed, but little or no adsorption of CH 4 . The natural gas in the low temperature state continuously passes through the system, and the solid adsorbent continuously degrades the CO in the natural gas. 2 Adsorption is carried out to achieve the purpose of purifying natural gas. Dynamic breakthrough curves such as Figure 7 shown. CH 4 The breakthrough time is 3140s, CO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com