Special lubricating oil for gas filling sub-station system

A technology for filling sub-stations and lubricating oil, which is applied in lubricating compositions, petroleum industry, etc., can solve the problems of not meeting the requirements of lubrication and gas push, and achieve the effects of excellent extreme pressure and anti-wear properties and reducing equipment noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

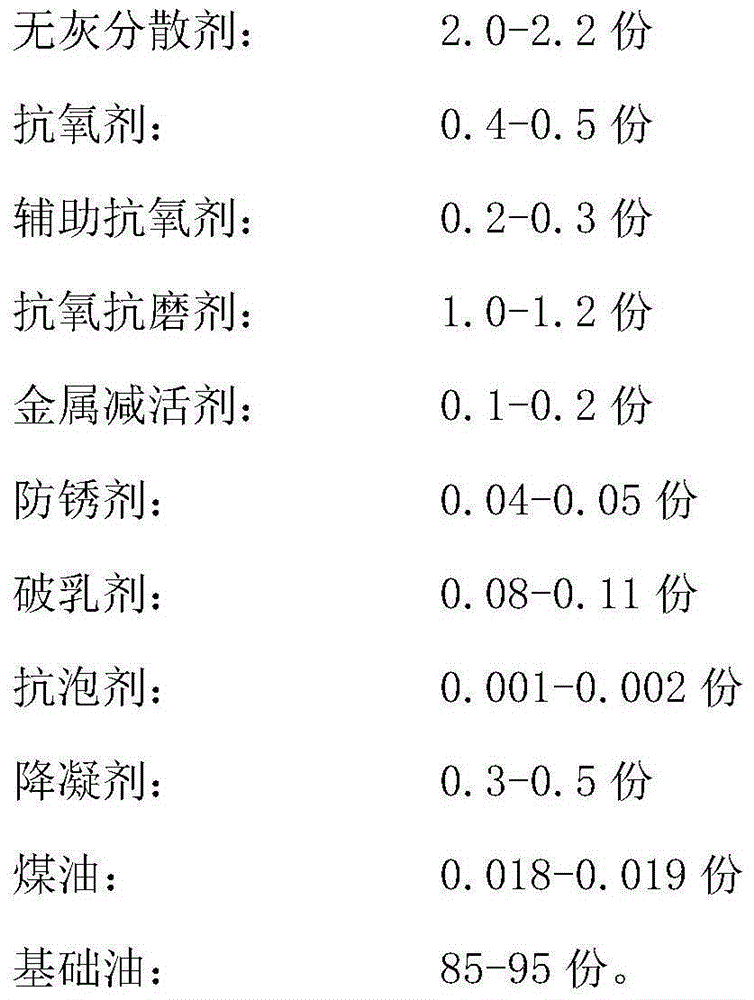

Method used

Image

Examples

Embodiment 1

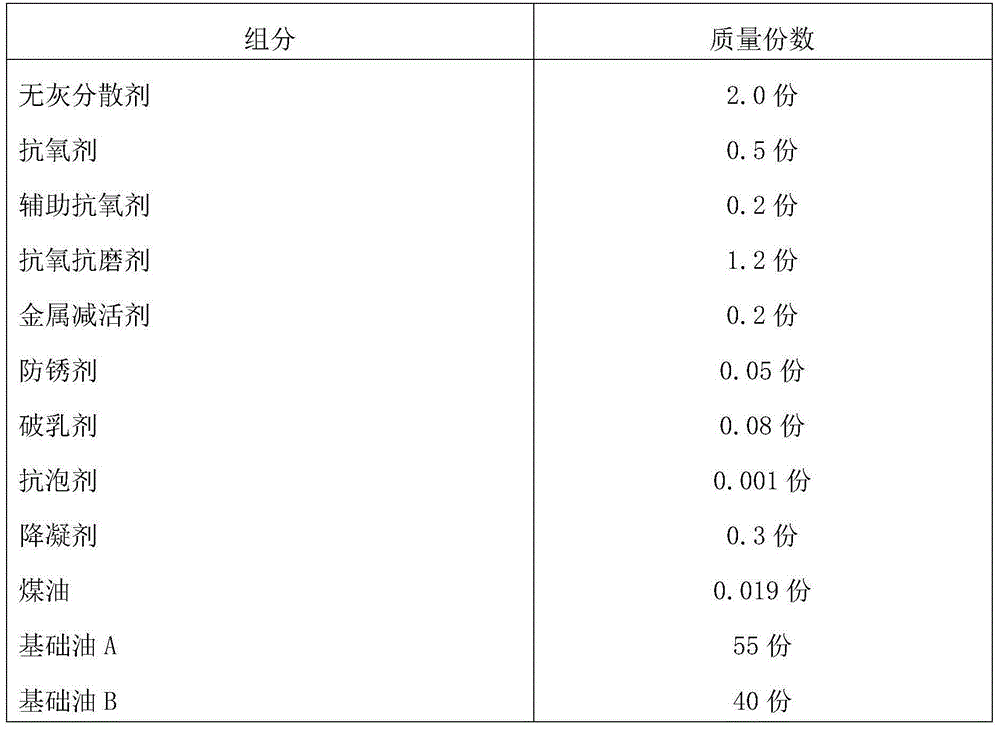

[0021] Example 1 is a full-component lubricating oil for 46# gas filling sub-station system, and the component contents are shown in Table 1.

[0022] Table 146# Concentration of special lubricating oil components in gas filling sub-station system

[0023]

[0024] The preparation method of the special lubricating oil for the gas filling sub-station system comprises the following steps:

[0025] Step a), pump 55kg of 150N hydrogenated base oil (base oil A) into a 150L blending kettle, and then pump 40kg of 500N hydrogenated base oil (base oil B). Stir and heat to 65±5°C to obtain the first mixture.

[0026] Step b), add 2000g of ashless dispersant, 500g of antioxidant, 200g of auxiliary antioxidant, 1200g of antioxidant and antiwear agent, 200g of metal deactivator, 300g of pour point depressant into the first mixture obtained in step a) respectively agent, keep the temperature at 65±5°C, and keep stirring for 45 minutes to obtain the second mixture.

[0027] Step c), us...

Embodiment 2

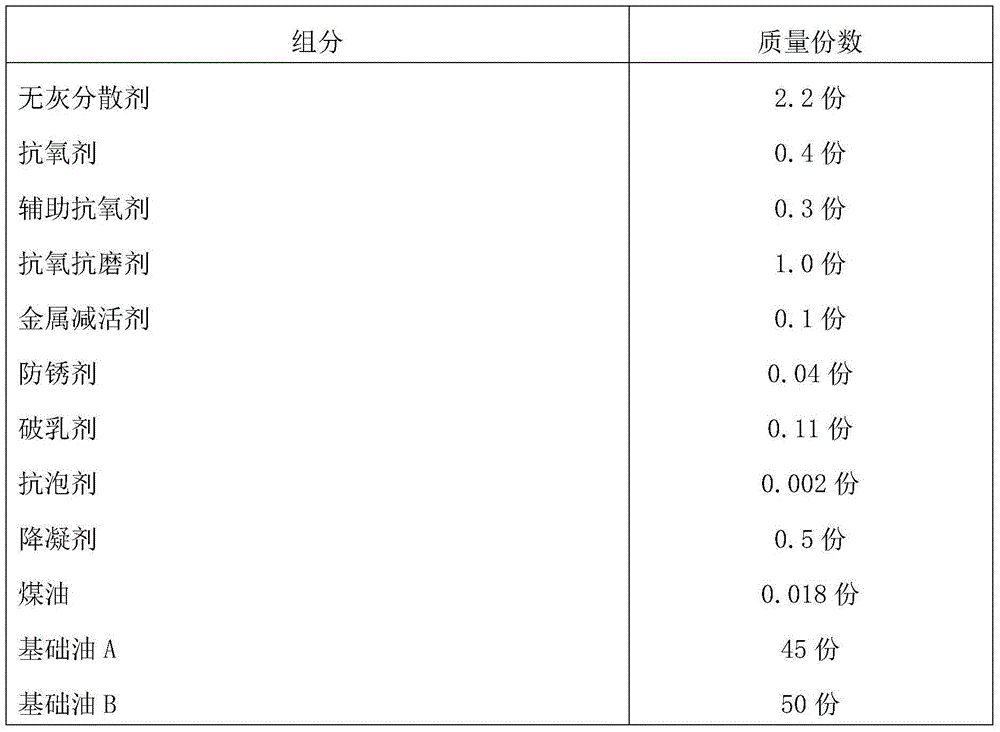

[0032] Example 2 is a special lubricating oil for the full-component 46# gas filling sub-station system. The component contents are shown in Table 2.

[0033] Table 246# Contents of special lubricating oil components in gas filling sub-station system

[0034]

[0035] The preparation method of the special lubricating oil for the gas filling sub-station system comprises the following steps:

[0036] Step a), pump 45kg of 150N hydrogenated base oil (base oil A) into a 150L blending kettle, and then pump 50kg of 500N hydrogenated base oil (base oil B). Stir and heat to 65±5°C to obtain the first mixture.

[0037] Step b), add 2200g of ashless dispersant, 400g of antioxidant, 300g of auxiliary antioxidant, 1000g of antioxidant and antiwear agent, 100g of metal deactivator, 500g of pour point depressant into the first mixture obtained in step a) respectively agent, keep the temperature at 65±5°C, and keep stirring for 45 minutes to obtain the second mixture.

[0038] Step c)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com