Cored wire of carbonate composite pure metal

A technology of cored wire and carbonate, which is applied in the field of melt purification and calcium treatment in iron and steel metallurgy, to achieve the effect of increasing the specific surface area, solving the problem of splashing, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

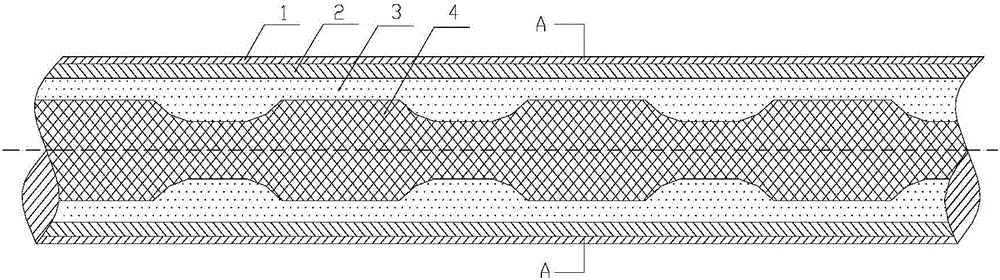

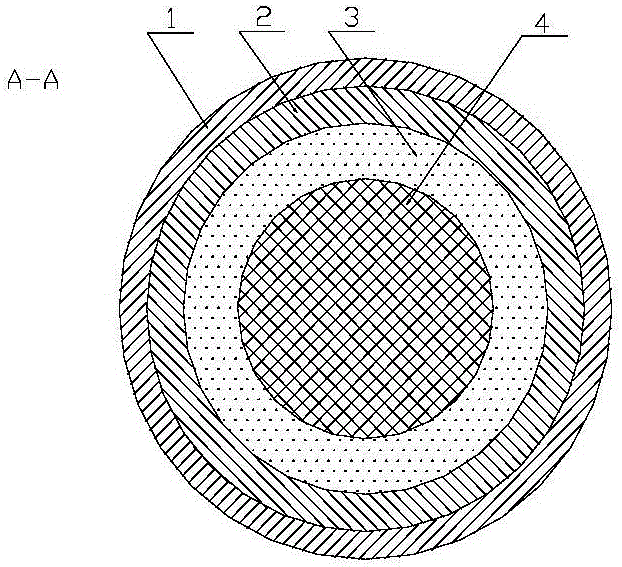

[0037] The cored wire is composed of outer steel strip, middle steel strip layer, carbonate powder layer and pure metal wire.

[0038] The outer layer is a cold-rolled steel strip with a thickness of 0.20mm, and the outer diameter of the cored wire is 8.0mm.

[0039] The middle layer is a 0.40mm cold-rolled steel strip, and the outer diameter of the middle layer made of a cored wire is 7.6mm.

[0040] The arc between the sealing part of the outer cladding layer and the sealing part of the middle layer is 120°.

[0041] The carbonate powder layer is analytically pure magnesium carbonate, the mass content is greater than 98%, and the particle size is less than 0.2mm.

[0042] The wire core is pure metal calcium wire, and the calcium mass content is greater than 99%.

[0043] The physical form of pure metal calcium wire is a bamboo-shaped structure, the length of the thick end is 0.01m, the diameter is 0.005m, the length of the thin end is 0.005m, and the diameter is 0.003m. 19±...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com