Supplemented-air-cooled central cylinder of cyclone separator

A cyclone separator and inner cylinder technology, which is applied to cyclone devices, fuels burning in a molten state, and devices whose axial directions of cyclones can be reversed, etc., to achieve the effects of reducing deformation, small changes, and good nitrogen oxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

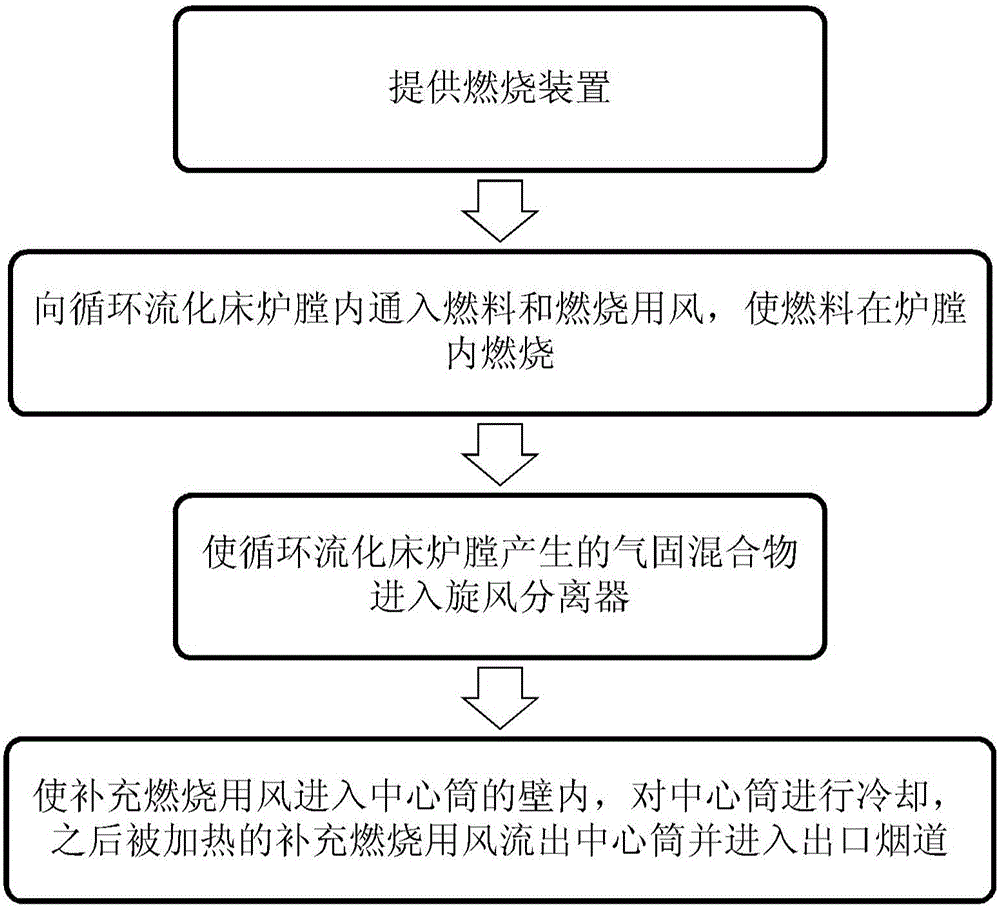

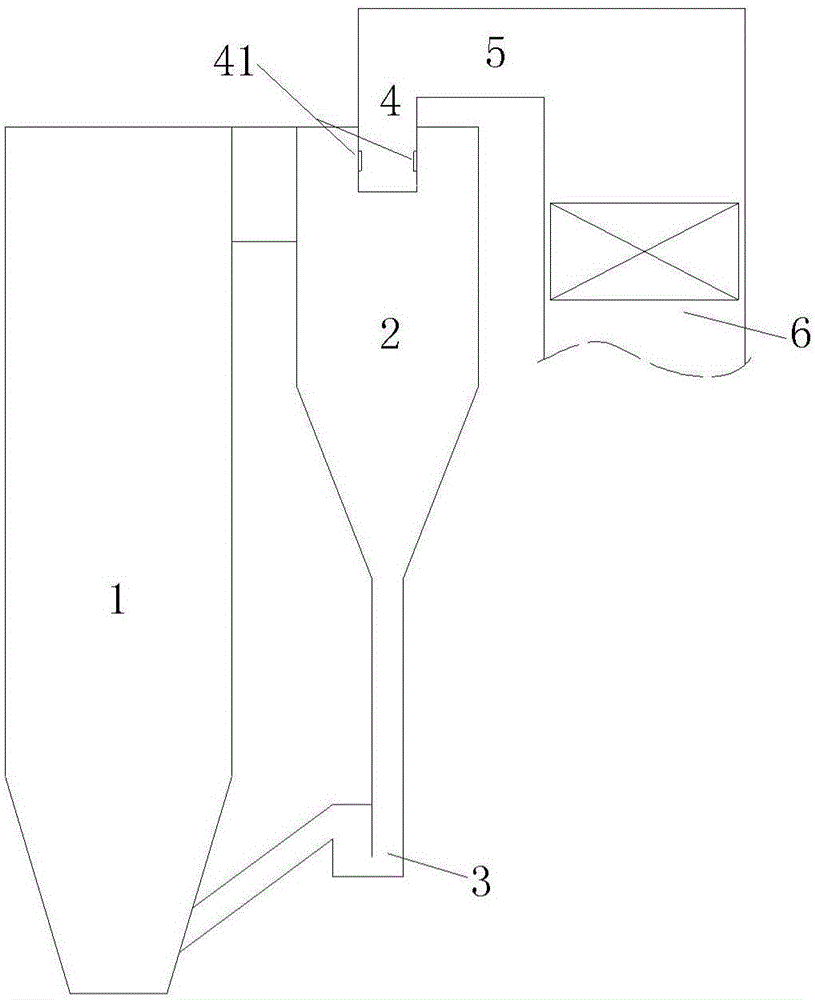

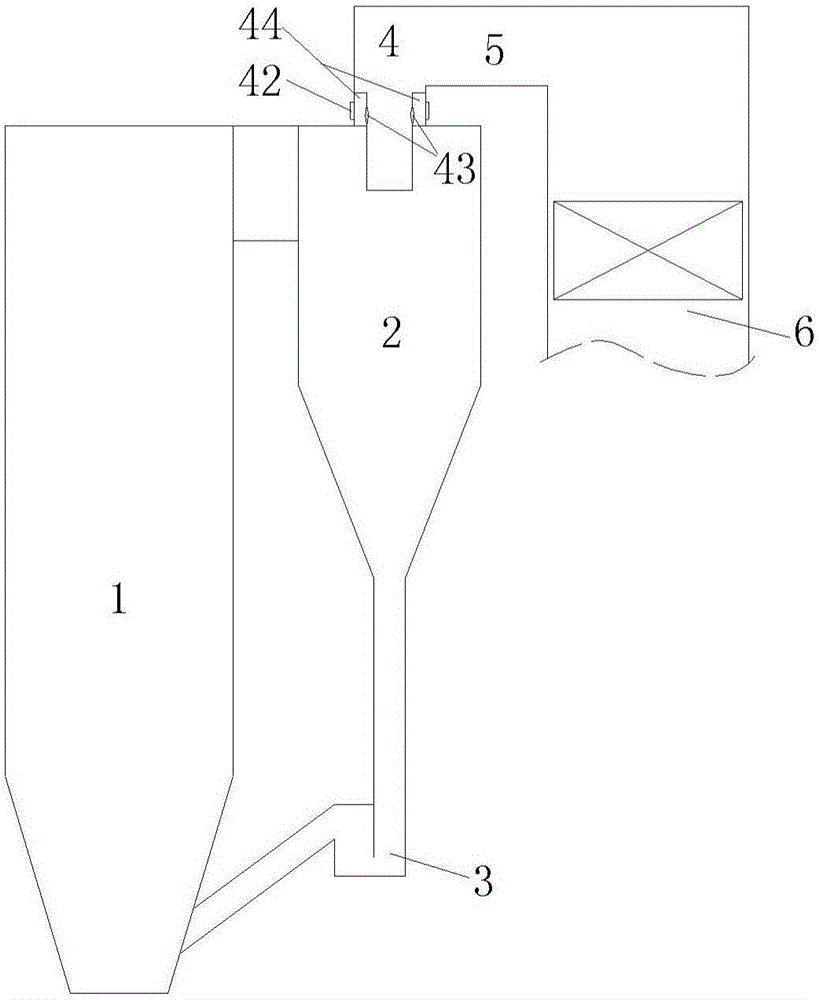

[0037] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements. In addition, in the following detailed description, for purposes of explanation, numerous specific details are set forth in order to provide a comprehensive understanding of the embodiments of the present disclosure. It may be evident, however, that one or more embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in diagrammatic form to simplify the drawings.

[0038] During the combustion process of fuel in the circulating fluidized bed, the nitrogen oxides (NOx) produced are mainly nitric oxide (NO), and its proportion is as high as 95%. Generally, the nitrogen source of NOx generated by coal combustion can be divided into fuel N and thermal N. The fuel nitrogen comes from the N in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com