Wet-type lampblack purification all-in-one machine

An oil fume purification and integrated machine technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of easy bacteria, inconvenient maintenance and cleaning, and long pipelines, so as to improve equipment utilization, facilitate cleaning and maintenance, and beautify The effect of building appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

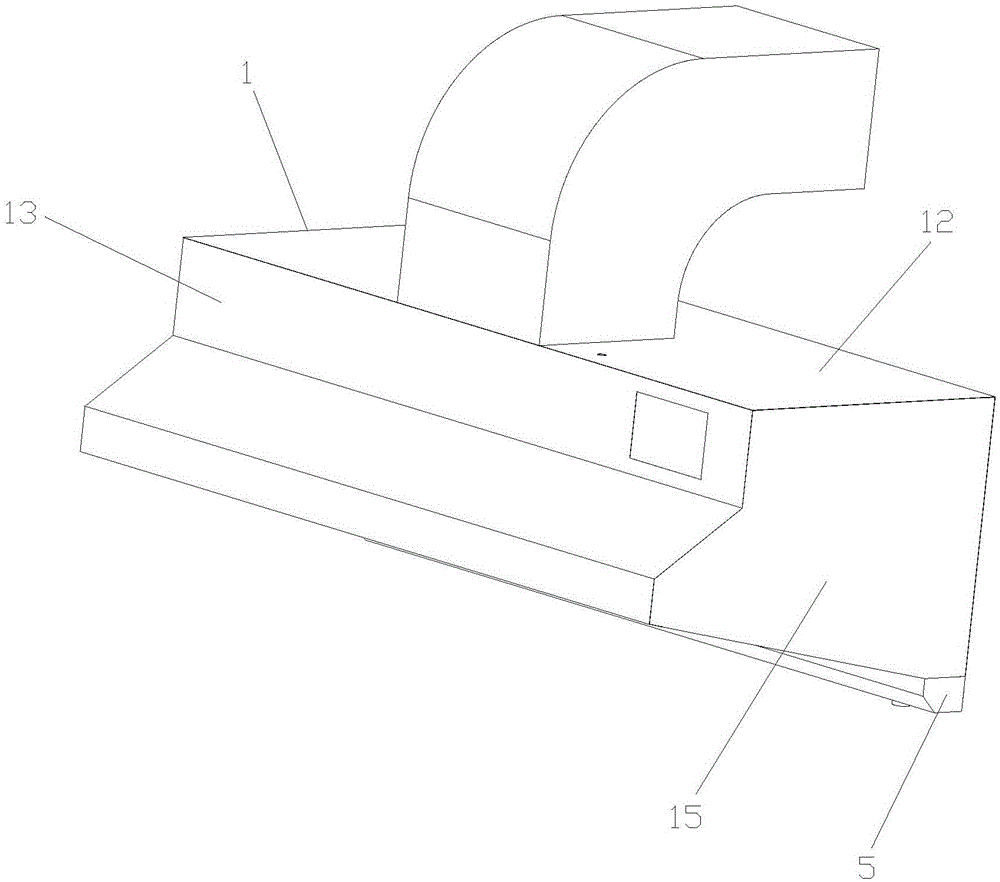

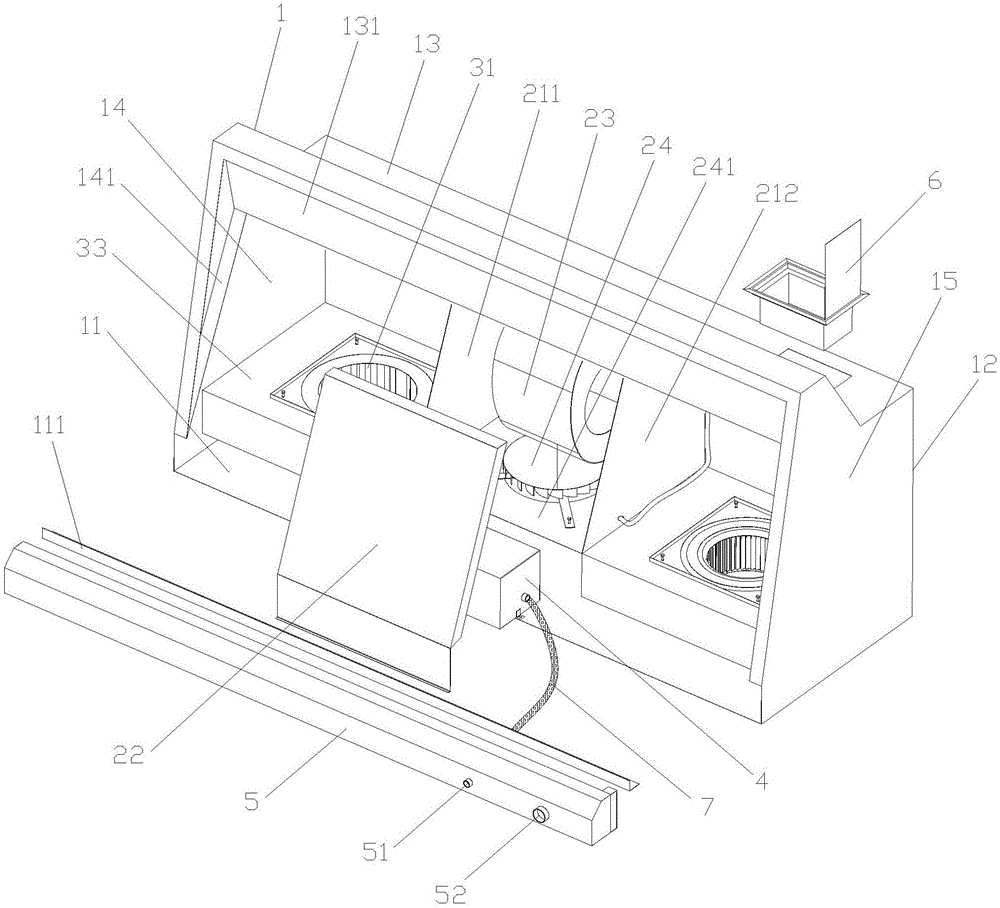

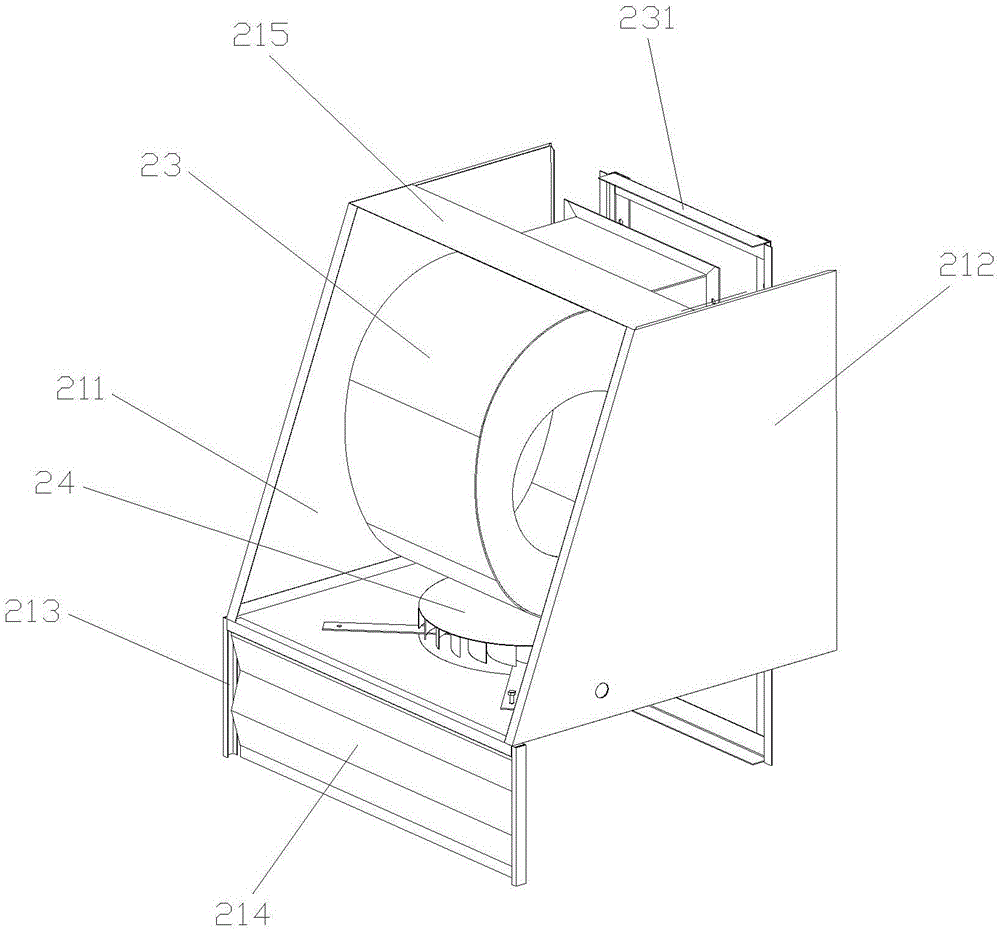

[0028] like Figures 1 to 6 As shown, the all-in-one wet oil fume purification machine of the present invention includes a hood casing 1 , a fan assembly 2 , a wind impeller assembly 3 , a water tank assembly 4 , a water tank 5 and an electrical box assembly 6 .

[0029] The hood casing 1 includes a back plate 11, a top plate 12, a front plate 13, a left side plate 14 and a right side plate 15; the back plate 11 is a rectangular plate structure and the bottom end is provided with an oil screen rear support 111; the top plate 12 Installed on the top of the back plate 11; the front plate 13 is installed on the front end of the top plate 12 and the bottom end is equipped with an oil screen front bracket 131; the left side plate 14 and the right side plate 15 are respectively installed on the back The left and right side ends of plate 11, top plate 12, front plate 13 are arranged in parallel with each other, the bottom end of this left side plate 14 is equipped with oil screen lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com