Ultraviolet temperature measuring method and apparatus for MOCVD epitaxial wafer surface temperature measurement

A surface temperature, epitaxial wafer technology, applied in the field of non-contact ultraviolet temperature measurement, can solve the problems of high cost, complex structure, and the magnification cannot meet the temperature measurement, and achieve the effect of high-precision measurement and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further introduced below in conjunction with the accompanying drawings.

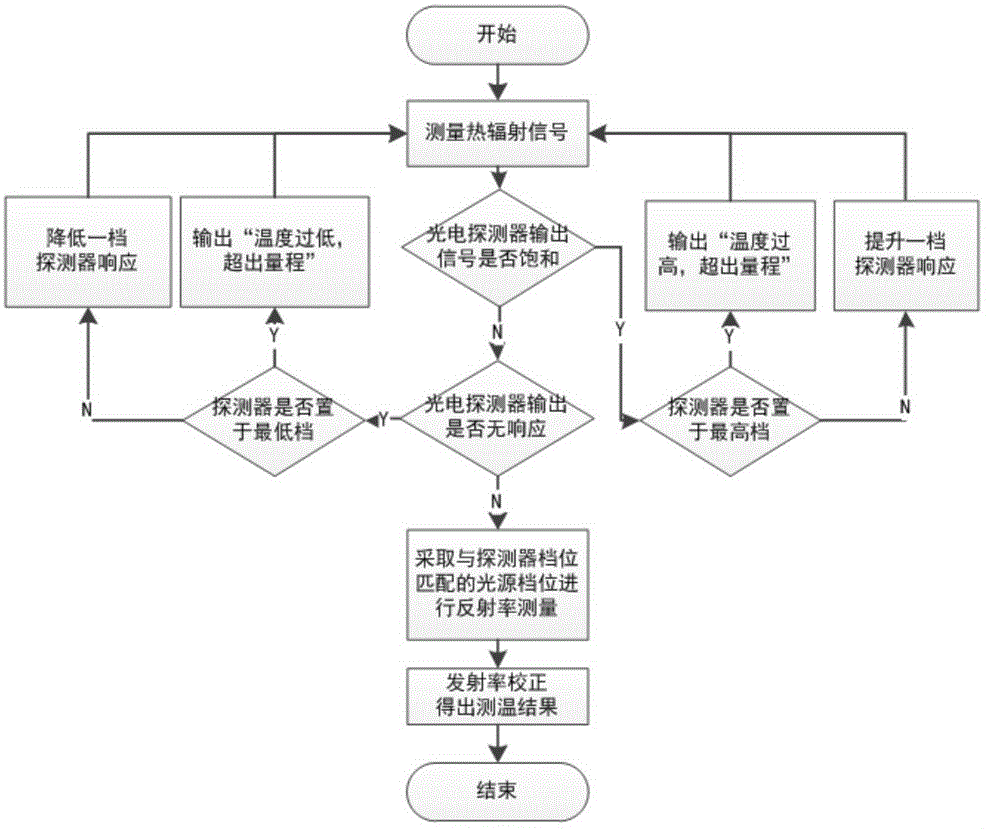

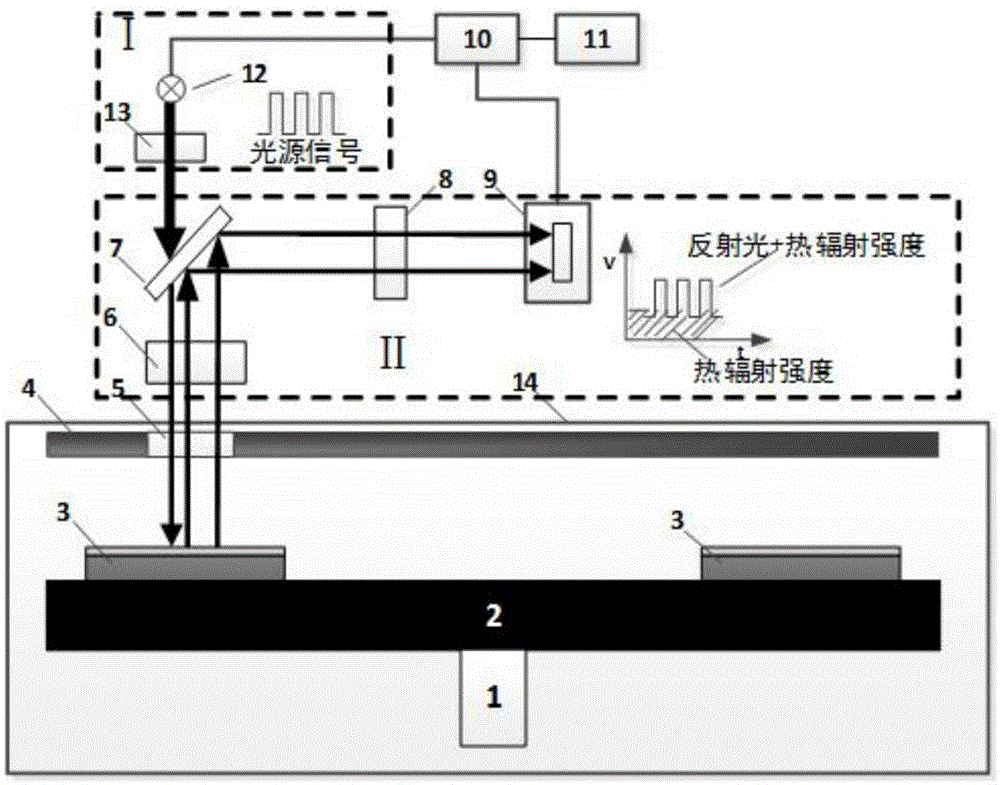

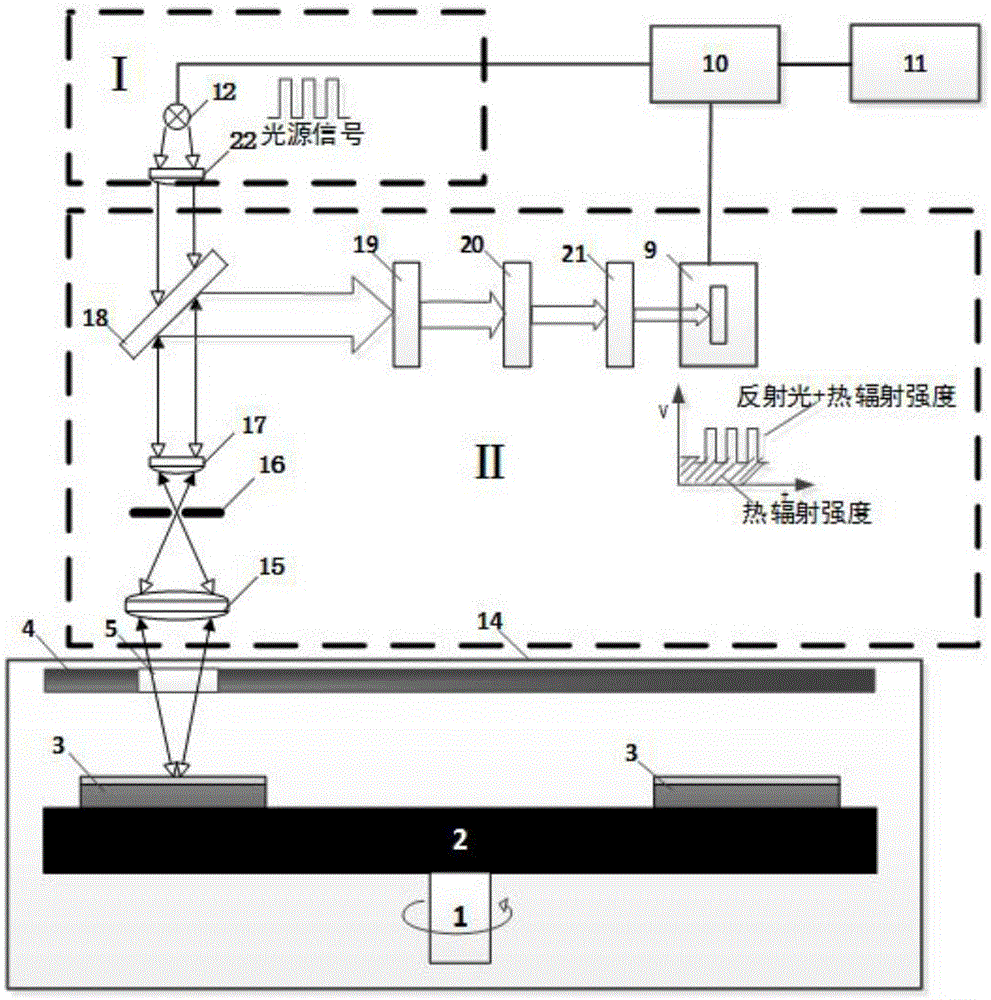

[0026] The invention automatically selects the response of the temperature-measuring photoelectric detector and the intensity of the light source used for measuring the reflectivity according to the measured thermal radiation signal strength of the measured object, thereby realizing high-precision measurement at different temperatures. figure 1 A flow chart of the temperature measurement method provided by the present invention. The gain of the photodetector of the present invention and the intensity of the light source used for measuring the reflectivity are adjustable. During the test, the temperature measurement range is first divided into two or more sub-ranges, and the corresponding photodetector gain gear of each sub-range and The intensity of the light source used to measure the reflectivity is different. The higher the gear, the higher the gain of the photodet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com