Operational optimization method for nitration and nitrosation processes

A technology for operation optimization and nitrosation, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as simulation of unammonia nitrogen nitration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

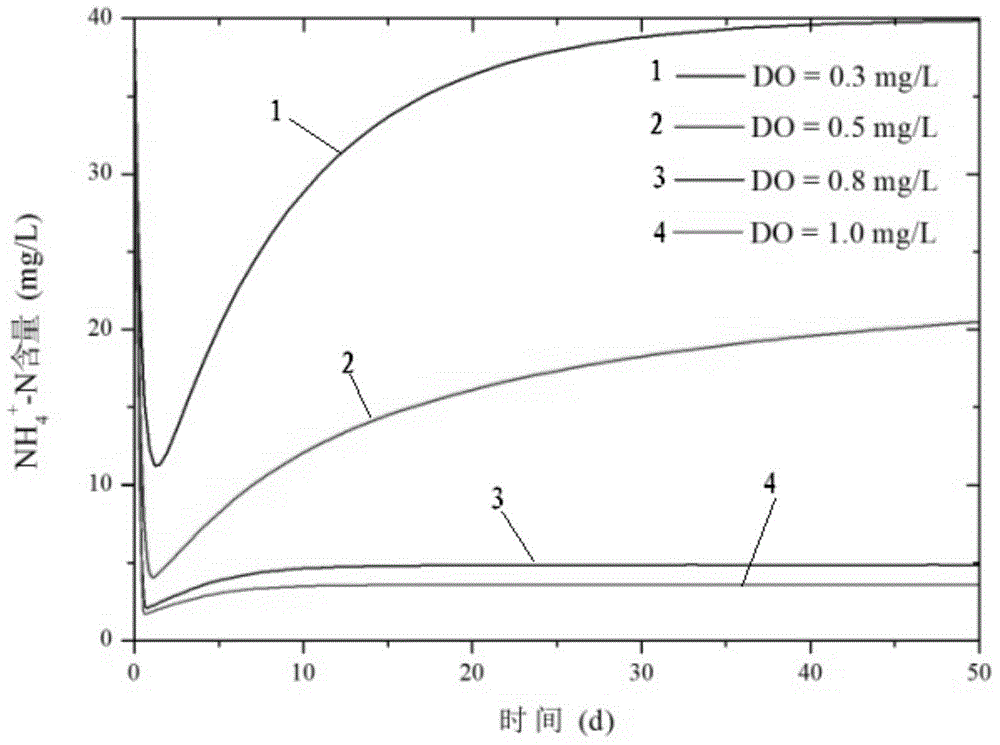

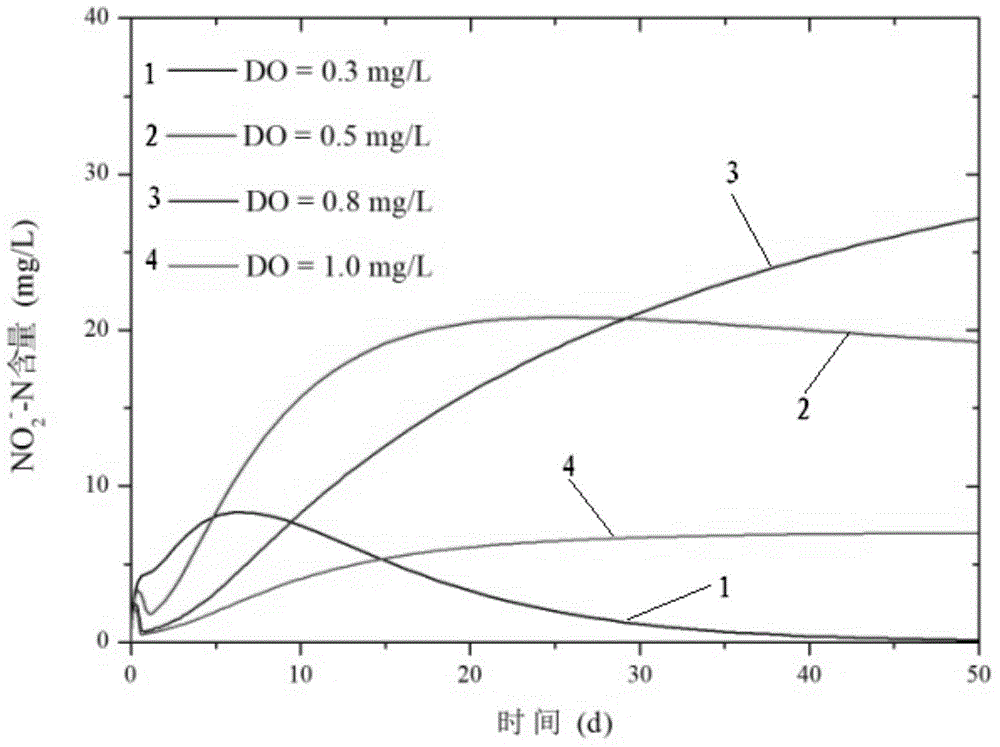

[0047] An operation optimization method for nitrification and nitrosation process, taking the continuous flow short-cut nitrification process to treat urban sewage as an example, using numerical analysis software (such as Mathematica, etc.) to simulate the biochemical tank and sedimentation tank in a certain sewage treatment process. The design requirements are that the ammonia nitrogen removal rate of the effluent should be more than 85%, and the nitrite accumulation rate should be more than 70%.

[0048] 1. Build a dynamic control system.

[0049] According to the characteristics of the process, a dynamic control system for the short-cut nitrification process is constructed, as follows:

[0050] 1. Establish the kinetic model of nitrosation and nitrification process.

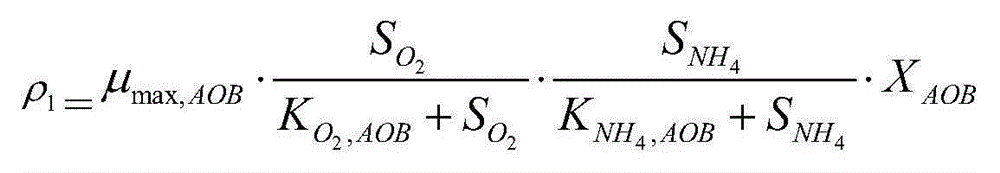

[0051] According to NH 4 + -N→NO 2 - -N and NO 2 - -N→NO 3 - -N The parameters involved in the two-step nitrification process, and the kinetic model of the nitrification and nitrification process were...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com