Minimum wetted perimeter volute section numerical value solving method based on speed moment conservation principle

A technology for volute section and numerical solution, which is applied in the fields of pumping device components for elastic fluids, electrical digital data processing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

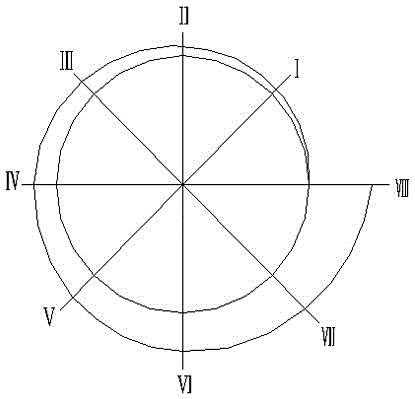

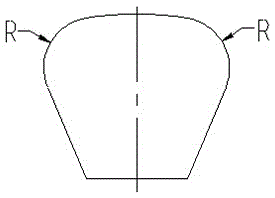

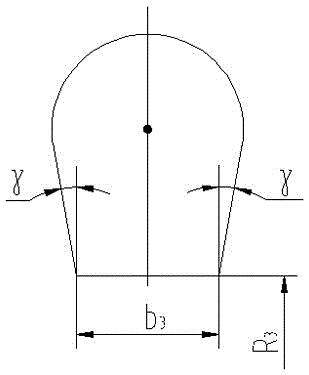

[0066] Although the circle has the minimum perimeter when the area is constant, as analyzed above, the section of the volute of the centrifugal pump should not be circular. In this patent, two symmetrical straight lines are still used at the lower part of the volute section on the axial surface to form an axial streamline without turning. The difference from the traditional trapezoidal section is that this patent replaces the traditional structure of two transitional arcs with a circular arc tangent to two straight lines, and its circumference will be significantly smaller than the traditional structure. The two straight waists at the lower part of this cross-section prevent the water from flowing out, and the bow formed by the single arc at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com