Feedback driving circuit

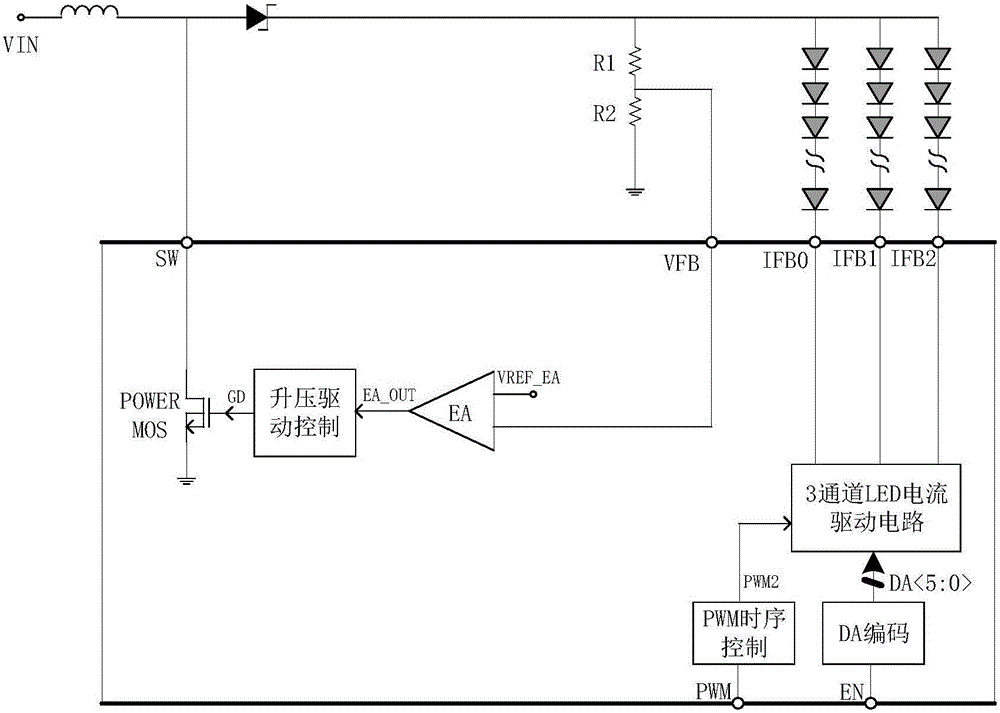

A driving circuit and feedback voltage technology, which is applied in the field of step-up high-voltage LED current drive circuit design, can solve the problems of affecting power utilization efficiency and VREF_LED voltage changes greatly, so as to save voltage divider feedback resistors, maintain voltage stability, apply simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

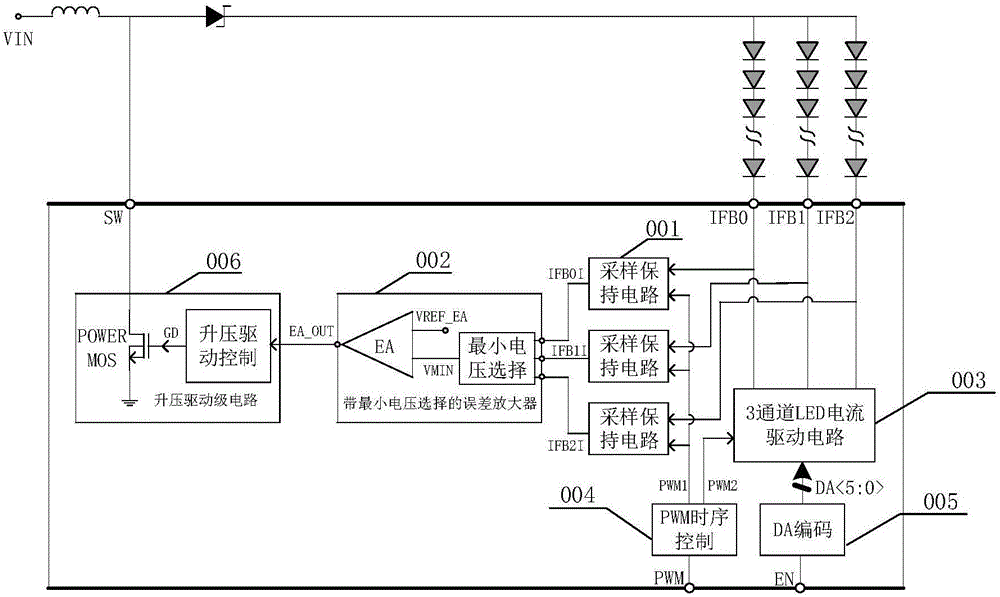

[0034] The circuit of the present invention ensures that the output voltage for driving the LED is high enough without increasing the chip area, and is an optimized output voltage, which fundamentally solves the problem of needing to calculate the feedback voltage divider resistance in different applications; maintains the external circuit The voltage stability not only saves the external voltage divider feedback resistor, but also makes the application simpler and improves the utilization efficiency of the power supply at the same time.

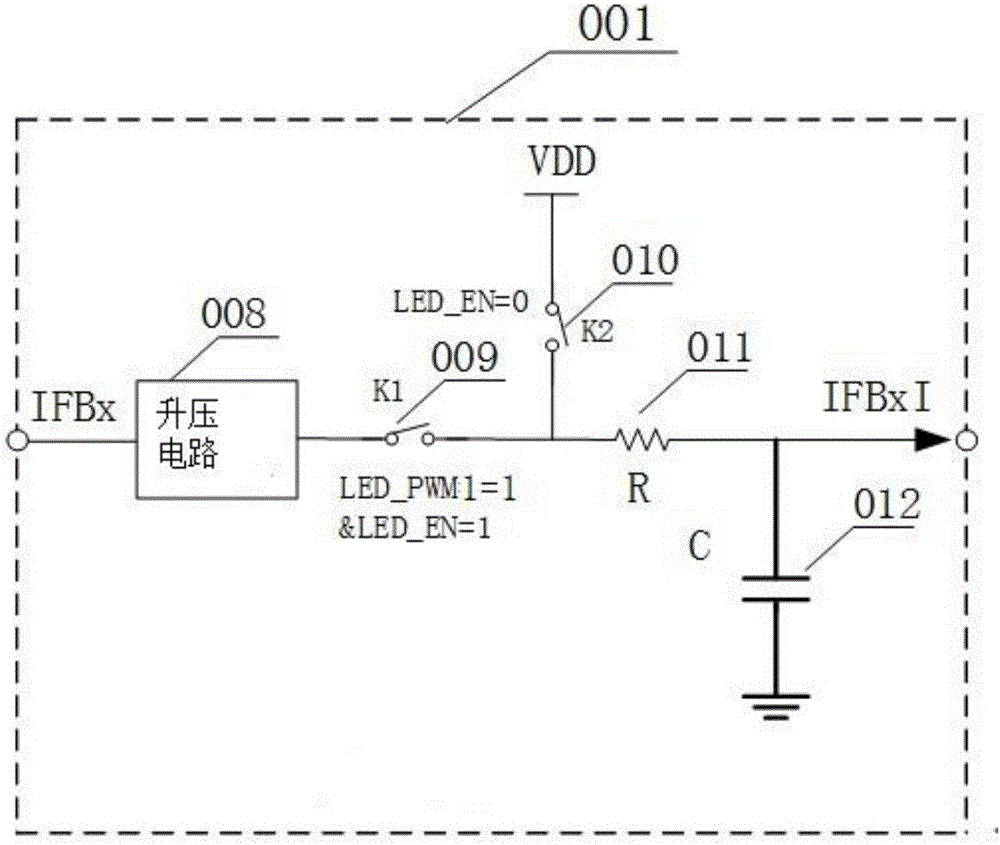

[0035] figure 2 It is a schematic diagram of a feedback driving circuit provided by an embodiment of the present invention. As shown in the figure, a feedback drive circuit includes a channel LED current drive circuit module 003, a boost drive stage circuit module 006, and at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com