Health reconciled milk beverage with nattokinase and preparation method thereof

A milk drink and soybean kinase technology, which is applied in the field of food and microbial fermentation engineering, can solve the problems of low popularity rate, not suitable for taste, complex preparation conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

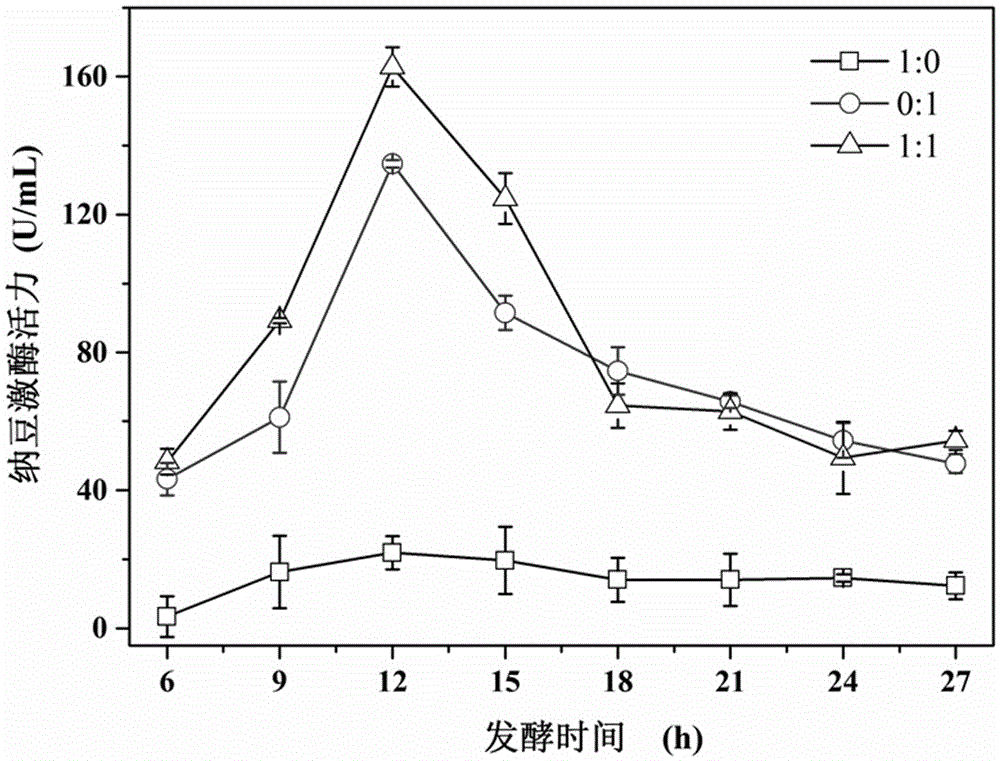

[0060] A health-care blended milk drink containing nattokinase in this embodiment is prepared from soybean milk, milk and natto Bacillus subtilis seed liquid.

[0061] The preparation method of a kind of health-care blended milk drink containing nattokinase of the present embodiment is:

[0062] Add 50g of soybeans to 450mL of water to make soybean milk, filter 3 times, and sterilize the filtrate at 115°C for 30min, then set aside. Dissolve 45g of milk powder into 300mL and sterilize at 65°C for 30min. After the above two kinds of liquids were uniformly mixed at a volume ratio of 1:1, 3% of the total volume of the mixed liquid was added to the logarithmic phase of Bacillus subtilis natto seed liquid, and the shake flask was fermented at 160rpm and 35°C for 12h.

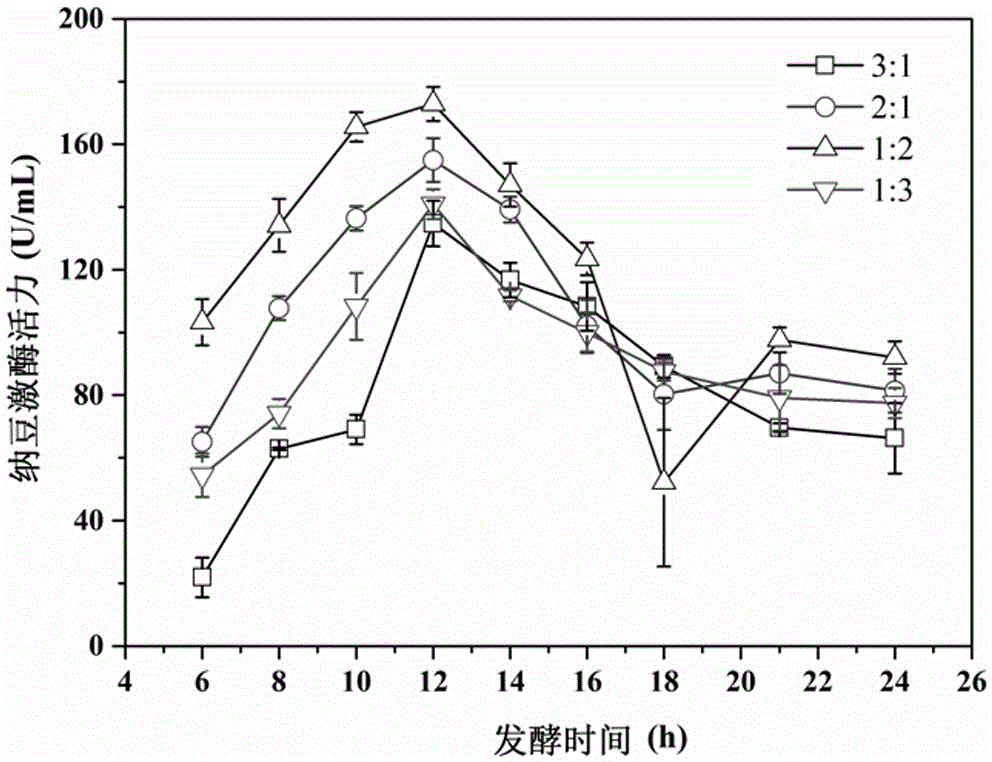

Embodiment 2

[0064] The difference between this example and Example 1 lies in that: the volume ratio of soybean milk and milk is 1:2; during fermentation, the shake bottle fermentation is carried out at 180 rpm and 40° C. for 8 hours.

Embodiment 3

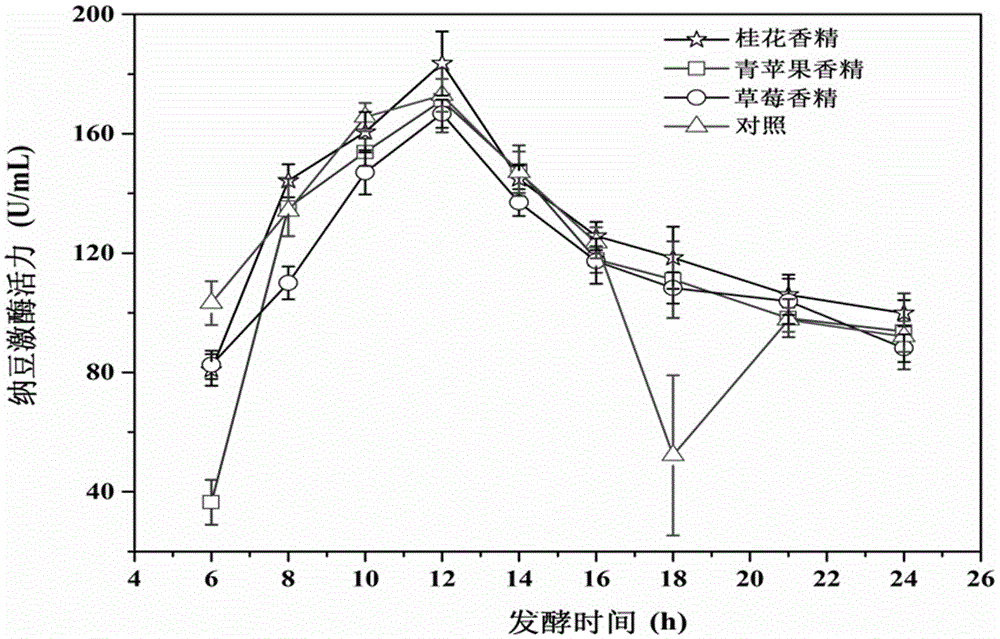

[0066] A health-care blended milk drink containing nattokinase in this embodiment is prepared from soybean milk, milk, essence and Bacillus subtilis natto seed liquid.

[0067] The preparation method of a kind of health-care blended milk drink containing nattokinase of the present embodiment is:

[0068] Add 50g of soybeans to 450mL of water to make soybean milk, filter 3 times, and sterilize the filtrate at 115°C for 30min, then set aside. Dissolve 45g of milk powder into 300mL and sterilize at 65°C for 30min. After the above-mentioned two kinds of liquids are uniformly mixed with a volume ratio of 1:2, the logarithmic phase Bacillus subtilis natto seed liquid with a total volume of 3% of the mixed solution is added, and sweet-scented osmanthus essence with a total volume of 1% of the mixed solution is added, 160rpm, 35 ℃ shake flask fermentation for 12h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com