Anti-glycation particles used for powder-type cosmetics and preparation method thereof

A technology of anti-glycation and cosmetics, applied in the field of ultra-fine functional materials, can solve the problems of inconspicuous effect, and achieve the effect of smooth hand feeling, good use feeling and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

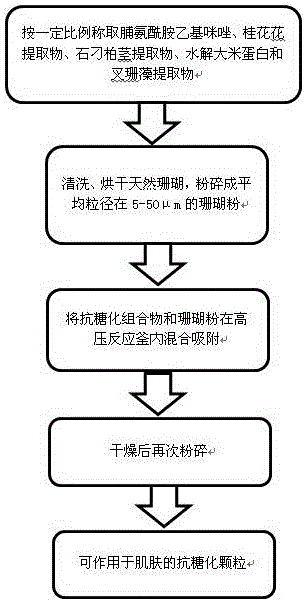

[0045] like figure 1 As shown, a preparation method of anti-glycation granules for powder cosmetics, comprising the following steps:

[0046] A. Weigh 10g of prolineamide ethylimidazole, 10g of Osmanthus fragrans extract, 30g of cypress stem extract, 30g of hydrolyzed rice protein, and 30g of hydrolyzed rice protein in a ratio of 1:1:3:3:1 by mass. 10 g of the product was heated to 50°C and stirred to obtain an anti-glycation composition;

[0047] B. Take the dried coral and wash it with deionized water with a conductivity of less than 10 μS / cm to remove the salt, until the conductivity of the cleaning water is less than 100 μS / cm. After drying and washing the cleaned coral, it is crushed into particles with an average particle size of 0.1mm by a ball mill, and then crushed into fine particles with an average particle size of 5-50μm by a jet mill for use;

[0048] C. Weigh 100 g of the anti-glycation composition prepared in step A and 50 g of coral particles prepared in ste...

Embodiment 2

[0051] An anti-glycation particle for powder cosmetics The preparation method comprises the following steps:

[0052] A. Weigh 10g of prolineamide ethylimidazole, 20g of osmanthus flower extract, 30g of cypress stem extract, 50g of hydrolyzed rice protein and algae extract in a ratio of 1:2:3:5:3 by mass ratio 30 g of the product was heated to 50°C and stirred evenly to obtain an anti-glycation composition;

[0053] B. Take the dried coral and wash it with deionized water with a conductivity of less than 10 μS / cm to remove the salt, until the conductivity of the cleaning water is less than 100 μS / cm. After drying and washing the cleaned coral, it is crushed into particles with an average particle size of 0.1mm by a ball mill, and then crushed into fine particles with an average particle size of 5-50μm by a jet mill for use;

[0054] C. Weigh 100 g of the anti-glycation composition prepared in step A and 100 g of coral particles prepared in step B in a mass ratio of 1:1, and...

Embodiment 3

[0057] An anti-glycation particle for powder cosmetics The preparation method comprises the following steps:

[0058] A. Weigh 20 g of prolineamide ethyl imidazole, 30 g of osmanthus flower extract, 40 g of cypress stem extract, 40 g of hydrolyzed rice protein and algae extract in a ratio of 1:2:3:5:3 by mass ratio 20 g of the product was heated to 50°C and stirred evenly to obtain an anti-glycation composition;

[0059] B. Take the dried coral and wash it with deionized water with a conductivity of less than 10 μS / cm to remove the salt, until the conductivity of the cleaning water is less than 100 μS / cm. After drying and washing the cleaned coral, it is crushed into particles with an average particle size of 0.1mm by a ball mill, and then crushed into fine particles with an average particle size of 5-50μm by a jet mill for use;

[0060] C. Weigh 100 g of the anti-glycation composition prepared in step A and 500 g of coral particles prepared in step B in a mass ratio of 1:5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com