Homogeneous olaquindox granules and preparation method thereof

A technology of olaquindox and granules, which is applied in the field of oxaethanol homogeneous granules and their preparation, can solve the problems of uniformity of polluted feed, sticking to walls, animal poisoning, etc., so as to improve intestinal bacteriostatic ability, reduce absorption, and reduce residues. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

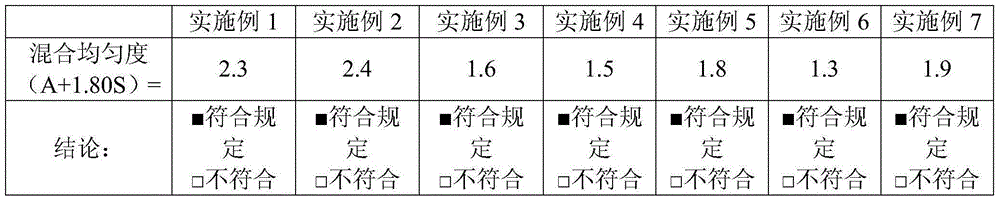

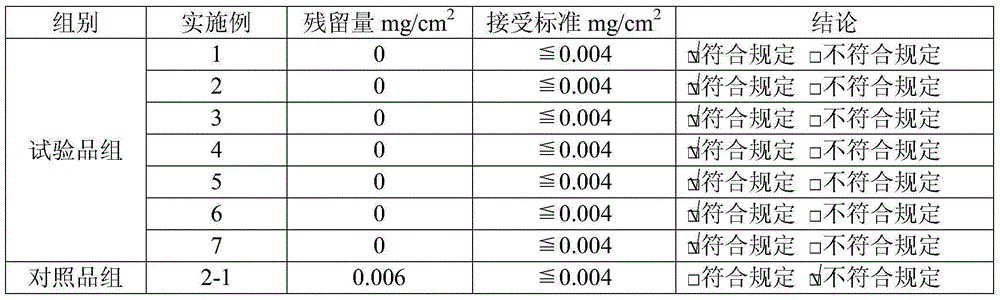

Examples

Embodiment 1

[0026] Weigh 2kg of olaquindox raw material and 98kg of hydrogenated castor oil for later use, first heat the hydrogenated castor oil to 90°C to melt and stir evenly, then mix the olaquindox raw material with the melted hydrogenated castor oil, shear and stir evenly to obtain the mixed solution; The mixed solution is sprayed, condensed and granulated to obtain the homogeneous olaquindox granules.

Embodiment 2

[0028] Weigh 10kg of olaquindox raw material and 90kg of polyethylene glycol 6000 for standby, first heat the polyethylene glycol 6000 to 65°C to melt and stir evenly, then mix the olaquindox raw material with melted polyethylene glycol 6000, shear and stir evenly The mixed solution is obtained; the mixed solution is sprayed, condensed and granulated, and the olaquindox homogeneous granules are obtained.

Embodiment 3

[0030] Weigh 20kg of the olaquindox raw material and 80kg of stearic acid for later use, first heat the stearic acid to 65°C to melt and stir evenly, then mix the olaquindox raw material with the melted stearic acid, shear and stir evenly to obtain the mixed solution; The mixed solution is sprayed, condensed and granulated to obtain the homogeneous olaquindox granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com