A method for co-producing ammonia from melamine tail gas

A co-production technology of melamine and tail gas, which is applied in separation methods, ammonia preparation/separation, chemical instruments and methods, etc., can solve problems such as blocked pipelines and easy crystallization, and achieve improved product benefits, less environmental pollution, and less volatilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

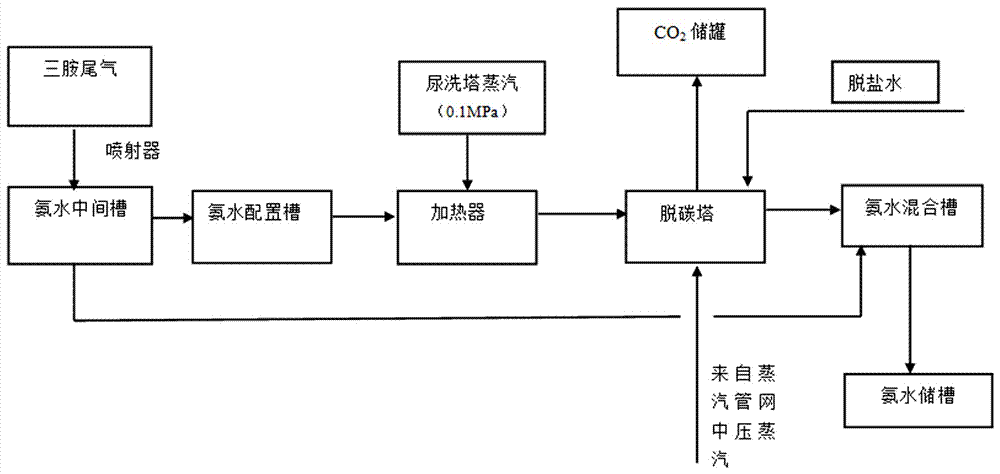

[0016] Refer to attached figure 1 , the specific operation is as follows:

[0017] After the melamine tail gas is sprayed and absorbed by the injector, it is made into high-concentration ammonia water (titer 270tt, CO 2 content 140ml / ml), enter the middle tank of ammonia water (due to CO in high-concentration ammonia water 2 The content is relatively high, it has reached a supersaturated state, and the degree of carbonization is about 100%, so it is easy to crystallize after the temperature cools down), turn on the circulation pump to circulate the high-concentration ammonia water, and after the high-concentration ammonia water is cooled to 54° by evaporative cooling, some The high-concentration ammonia water is sent to the ammonia water configuration tank through the ammonia water intermediate pump, and at the same time, some desalted water from the utility pipe network is added to the ammonia water configuration tank to dilute the ammonia water concentration in the ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com