Three-layer solid board

A technology of solid wood boards and panels, applied in the field of furniture materials, can solve the problems of difficult to achieve large-scale overall formwork, damage to the fiber structure of thin wood veneers, and difficult furniture materials, etc., to achieve changing instability, high mechanical strength, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

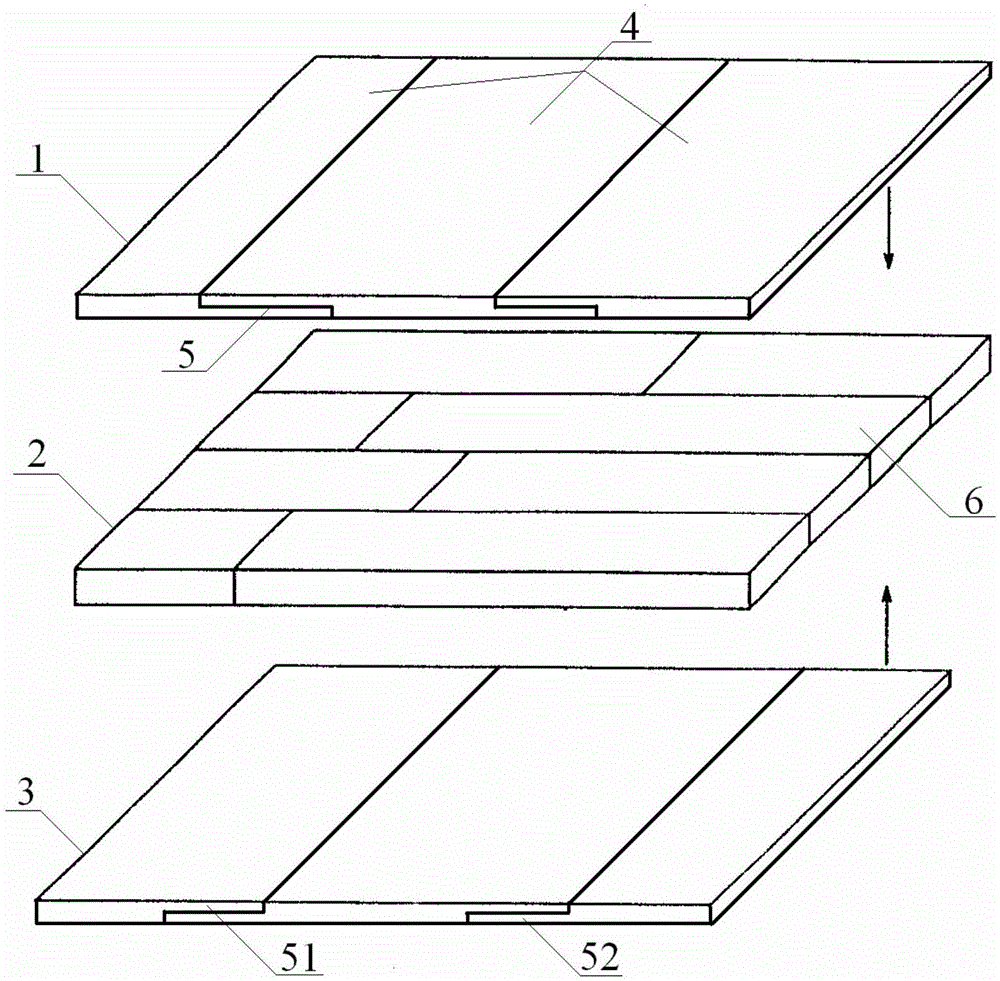

[0026] see figure 1 : a three-layer solid wood board, comprising an upper panel 1, a core panel 2 and a lower panel 3 which are sequentially glued together from top to bottom. Wherein, the upper panel 1 and the lower panel 3 include several sawn veneers 4, and the two sides of the veneer 4 are provided with adhesive parts 5, and the upper panel 1 is formed by bonding the veneers through the adhesive parts 5. and lower panel 3. The core board 2 is spliced by several sawn wooden strips 6 .

[0027] The bonding part 5 includes an upper bonding part 51 and a lower bonding part 52 , the thickness of the upper bonding part 51 and the lower bonding part 52 are both half of the thickness of the veneer 4 .

[0028] The core board 2 is formed by a plurality of sawn wooden strips 6 which are criss-crossed and spliced.

[0029] The veneer 4 can be rectangula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com