Fiber-reinforced thermosetting plastic corrugated pipe production equipment and process

A fiber reinforced and production equipment technology, which is applied in the field of fiber reinforced thermosetting plastic corrugated pipe production equipment and production technology, can solve the problems of inability to achieve safe and fast cable threading, uneven quality of power pipes, and small space for thermal energy dissipation, and achieve thermal energy. Large circulation range, simple design, and the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

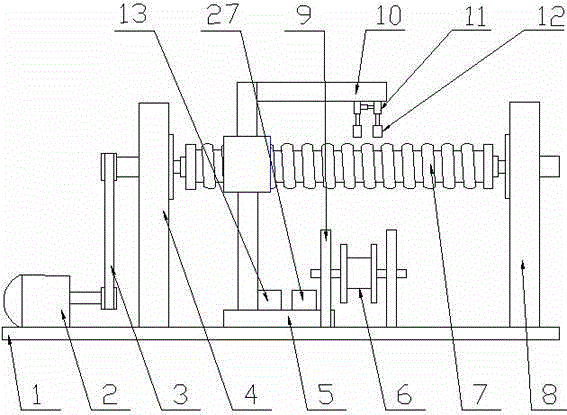

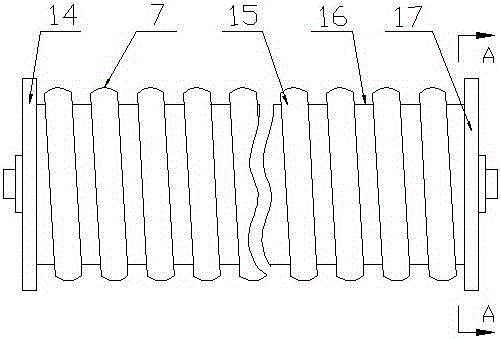

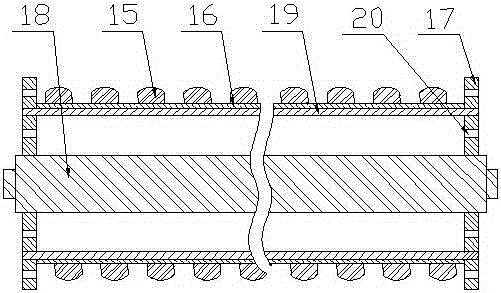

[0044] as attached figure 1 , 2 As shown, a pipe-making equipment for producing fiber-reinforced thermosetting plastic bellows of the present invention includes a base 1, a left mandrel support 4, a right mandrel support 8, a mandrel 7, a strip frame 9, a walking trolley 5 and a press wheel device. The left and right mandrel supports 4,8 are arranged on the base 1, and the mandrel 7 is rotated between the left and right mandrel supports 4,8. The corrugated surface formed by winding the rubber rope 15 includes arched crests and flat troughs, and the arched crests and flat troughs are connected by arc transitions, and the crests of the corrugated surface expand spirally along the axial direction. The strip frame 9 and the walking trolley 5 are arranged on one side of the mandrel 7, the strip frame 9 is provided with a strip winding wheel 6, and the strip winding wheel 6 is used to place rolls of fiber strip profiles, specifically including glass fiber felt, Roving fiberglass ...

Embodiment 2

[0054] as attached Figure 8 As shown, the second embodiment is the same as the first embodiment, the difference is that the corrugated surface is formed by connecting arc-shaped crests and circular-arc-shaped troughs, and the crests of the corrugated surface expand helically along the axial direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com