Automatic sizing roiling-up device

A one-to-one, fixed frame technology, applied in the direction of coiling strips, transportation and packaging, thin material processing, etc., can solve the problems of on-site management and production inconvenience, low production efficiency, and occupying workshop space, so as to broaden the scope of use, Improve mobility and save time in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

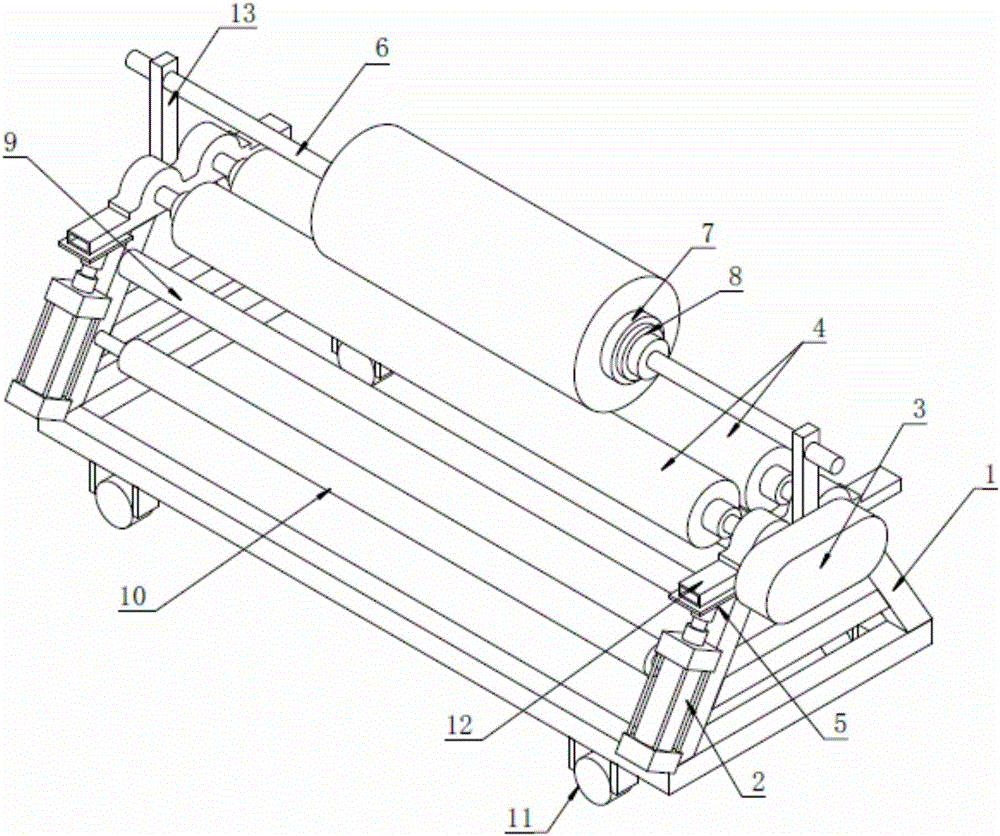

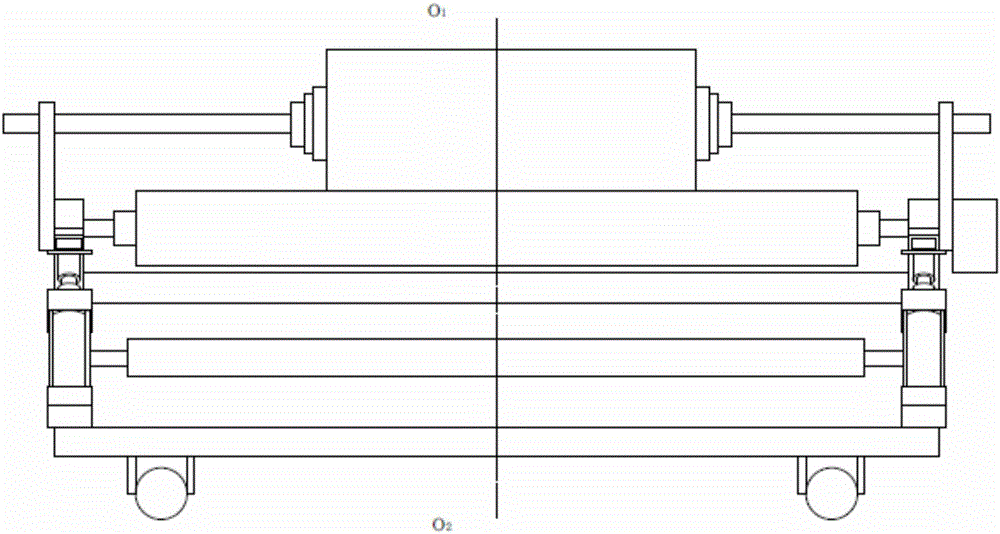

[0025] Such as figure 1 and 2 As shown, a stereotyped self-rolling device includes a bracket 1, a pair of cylinders 2, a transmission motor 3, a pair of support rollers 4, a limit rod 6, two cloth guide sticks and a pair of support rods 13, and is characterized in that : the support 1 is made up of two trapezoidal side supports and a long bar connecting the two trapezoidal side supports, the long side of the trapezoidal side support is on the bottom, and the short side is on the top, and the pair of cylinders 2 are along the center of the support 1 Line 0 1 0 2 Symmetrical, installed on both sides of the trapezoidal side bracket, and the side of the bracket on the same side as the cylinder 2 is sequentially installed with two cloth guide sticks from bottom to top, the pair of support rollers 4 and the bracket 1 The long rods are parallel and installed on the fixed frame 12 above the upper crossbeam of the two trapezoidal side brackets. One side of the fixed frame 12 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com