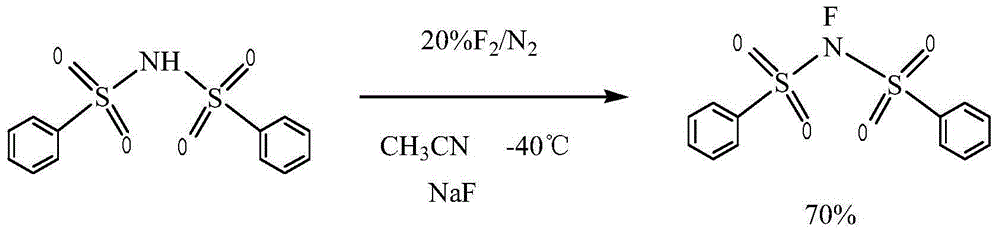

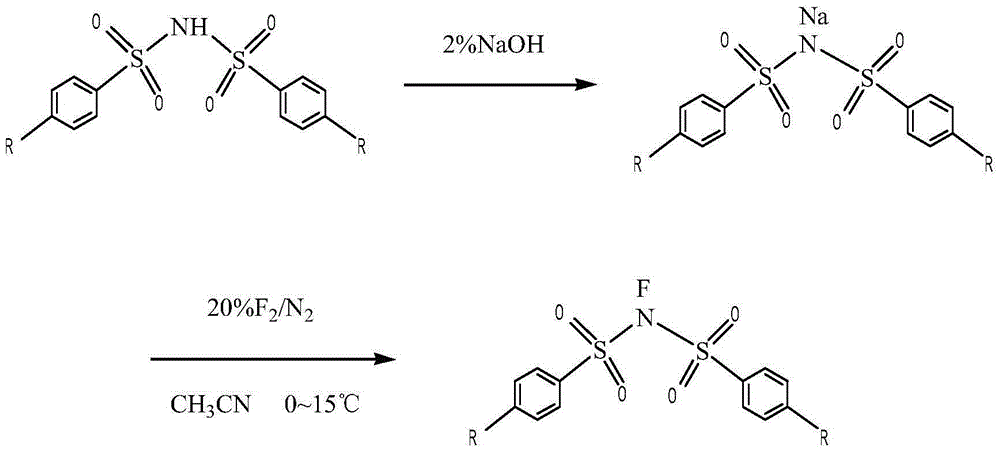

Novel process for preparing N-fluorobenzenesulfonimide with one-step method

A fluorobisbenzenesulfonimide, a new process technology, applied in the field of one-step preparation of N-fluorobisbenzenesulfonimide, can solve the problem of low reaction temperature, low yield, N-fluorobisphenyl Solve the problem of unsafe preparation reaction of sulfonimide, and achieve the effect of less side reactions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

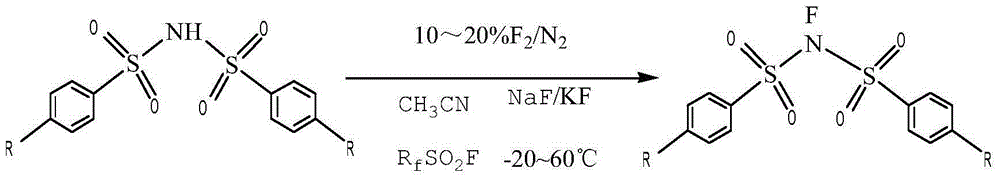

[0027] The synthesis of embodiment 1-15N-fluorinated bisbenzenesulfonylimide

[0028] First, fully stir the p-substituted bisbenzenesulfonimide, metal fluoride and perfluoroalkylsulfonyl fluoride with industrial acetonitrile; The gas is introduced from the final reaction tower; during the reaction process, the flow rate of the fluorine-nitrogen mixed gas is controlled to ensure that the reaction is carried out gently between -20 ° C and 60 ° C; after the reaction is completed, suction filtration, washing, and recrystallization are obtained. N-fluorobisbenzenesulfonimide.

[0029] Table 1 lists the data for the synthesis of N-fluorobisbenzenesulfonimide under different reaction conditions.

[0030] The list of experimental data of table 1 embodiment

[0031]

[0032]

[0033]

[0034] The above data show that:

[0035] 1: Whether to add perfluorobutylsulfonyl fluoride to the reaction system will significantly affect the yield of N-fluorobisbenzenesulfonimide. The o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap