Electromagnetic valve assembly of electronic jacquard machine

A solenoid valve component and electronic jacquard technology, applied in jacquard machines, textiles, textiles and papermaking, etc., can solve problems such as short service life, non-wear resistance, and increased energy consumption, and achieve improved service life, less wear and tear, and reduced energy consumption the effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

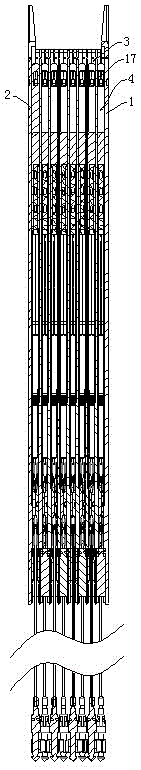

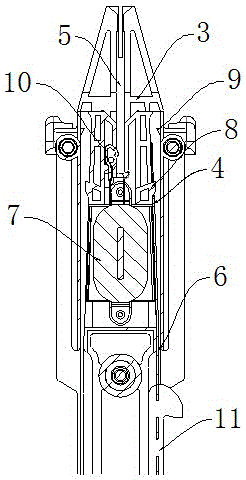

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the electromagnetic valve assembly of the electronic jacquard machine described in this embodiment includes a base plate 1, a panel 2 and several splints 3 arranged between the base plate 1 and the panel 2, and at the top of the base plate 1, the panel 2 and the splint 3 A groove 5 for PCB board insertion is provided, an electromagnet 7 is arranged in the splint 3 below the groove 5, and the electrode 10 of the electromagnet 7 extends into the groove 5; Vertical passage 6, the width of the vertical passage 6 above the electromagnet 7 lower end faces is greater than the width of the vertical passage 6 below, and the side of the electromagnet 7 is slightly lower than the side of the vertical passage 6; A suction piece 4 is arranged inside, and the suction piece 4 slides up and down in the vertical passage 6; a boss 8 is arranged on the side wall of the vertical passage 6 above the electromagnet 7, and the bo...

Embodiment 2

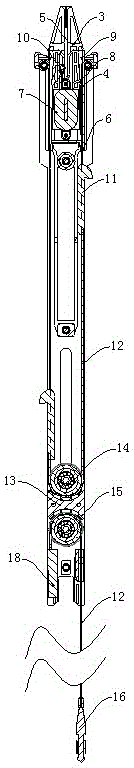

[0024] Such as Figure 5 , Figure 6As shown, the electromagnetic valve assembly of the electronic jacquard machine described in this embodiment includes a base plate 1, a panel 2 and several splints 3 arranged between the base plate 1 and the panel 2, and at the top of the base plate 1, the panel 2 and the splint 3 A groove 5 for PCB board insertion is provided, an electromagnet 7 is arranged in the splint 3 below the groove 5, and the electrode 10 of the electromagnet 7 extends into the groove 5; Vertical passage 6, the width of the vertical passage 6 above the electromagnet 7 lower end faces is greater than the width of the vertical passage 6 below, and the side of the electromagnet 7 is slightly lower than the side of the vertical passage 6; A suction piece 4 is arranged inside, and the suction piece 4 slides up and down in the vertical passage 6; a boss 8 is arranged on the side wall of the vertical passage 6 above the electromagnet 7, and the boss 8 protrudes from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com