A kind of paper-based friction material for adaptive automatic transmission and manufacturing method

A paper-based friction material, automatic transmission technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, paper, papermaking, etc. problem, to achieve the effect of excellent durability, stable friction performance, and small thermal recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

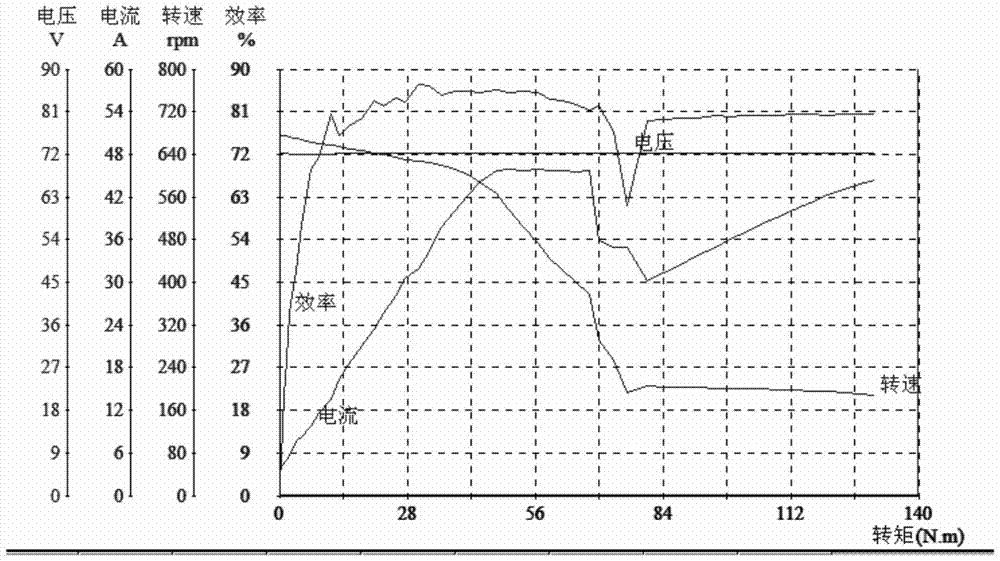

Embodiment 1

[0024] Embodiment 1, with the carbon fiber of 12 parts by weight, the aramid fiber pulp of 15 parts by weight, 10 parts by weight of modified phenolic resins, 9 parts by weight of powdered nitrile rubber, 5 parts by weight of graphite, 12 parts by weight of vermiculite, 18 parts by weight of Put diatomaceous earth, 3 parts by weight of friction powder and 0.5 parts by weight of slurry additive into a mixer, and stir for 5 minutes at a speed of 1000-1500r / min to make it evenly mixed into a mixed dry material; mix the dry material 15 parts by weight of cellulose paper are put into the beating tank, injected with water and nitrile latex, wherein the weight ratio of the mixed dry material, the sum of cellulose paper and water is 8:42; then stir in the pulp tank for 4 hours, after stirring evenly Input it into the refining tank for refining for 1 hour to make a uniform mixed slurry. Pass the mixed slurry through the automatic papermaking forming drying line at a uniform speed, and ...

Embodiment 2

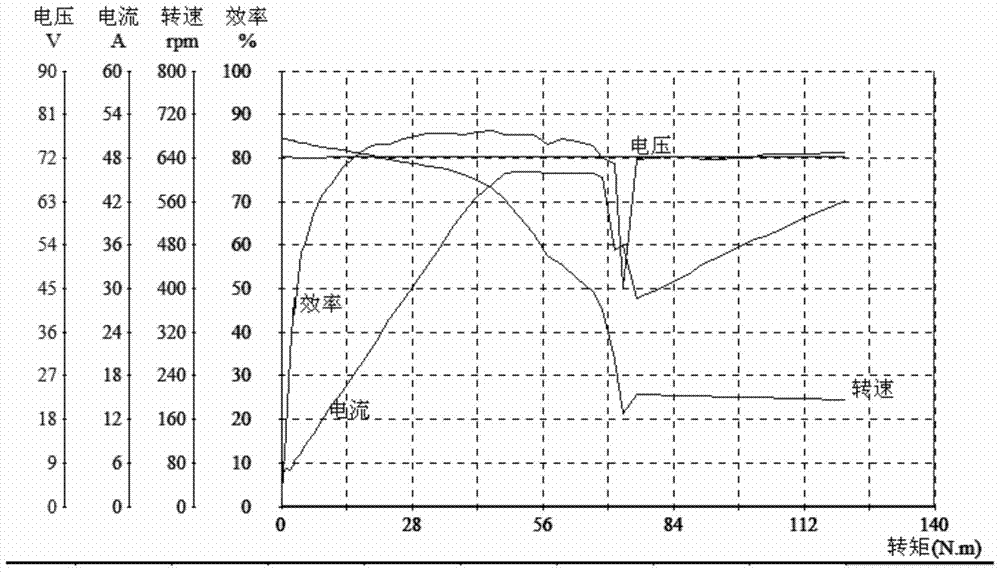

[0025] Embodiment 2, with the carbon fiber of 10 parts by weight, the aramid fiber pulp of 13 parts by weight, 13 parts by weight of modified phenolic resins, 7 parts by weight of powdered nitrile rubber, 7 parts by weight of graphite, 10 parts by weight of vermiculite, 16 parts by weight Diatomaceous earth, 5 parts by weight of friction powder and 0.8 parts by weight of slurry additives are put into a mixer, stirred at a speed of 1000-1500 r / min for 5 minutes, and mixed evenly to obtain a mixed dry material. Put the mixed dry material and 18 parts by weight of cellulose paper into the beating tank, inject water and nitrile latex, wherein the weight ratio of the mixed dry material, cellulose paper and water is 7.5:42.5; stir in the pulp tank for 4 hours, After stirring evenly, input it into the refining pool for refining for 1 hour to make a uniform mixed slurry. Pass the mixed slurry through the automatic papermaking forming drying line at a constant speed, and precisely cont...

Embodiment 3

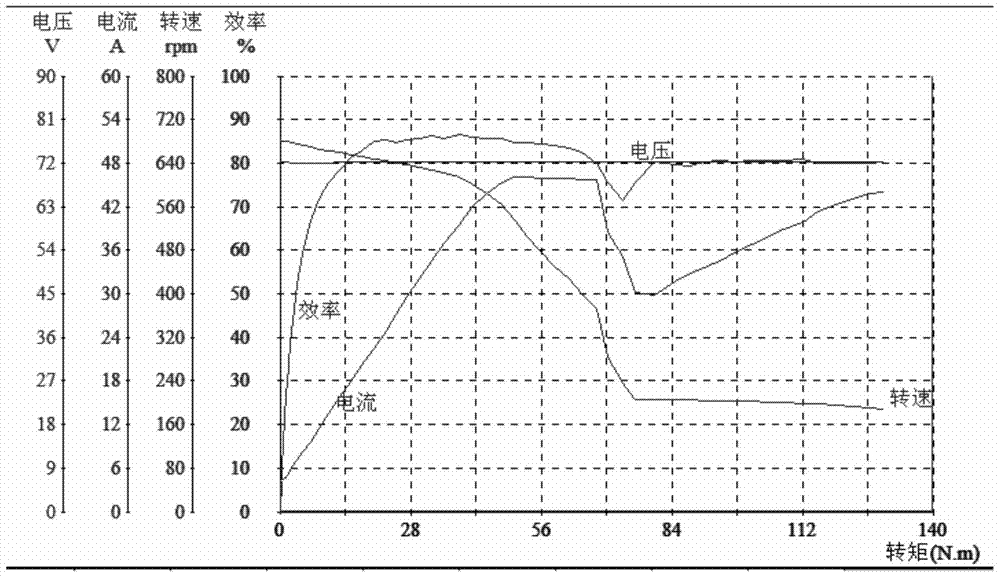

[0026] Embodiment 3, with the carbon fiber of 9 parts by weight, the aramid fiber pulp of 10 parts by weight, 15 parts by weight of modified phenolic resins, 5 parts by weight of powdered nitrile rubber, 9 parts by weight of graphite, 8 parts by weight of vermiculite, 15 parts by weight of Diatomaceous earth, 8 parts by weight of friction powder and 1 part by weight of slurry additive are stirred at a high speed of 1000-1500 r / min for 5 minutes to make them evenly mixed to obtain a mixed dry material. Put the mixed dry material and 20 parts by weight of cellulose paper into the beating tank, inject water and nitrile latex, and the weight ratio of the mixed dry material, cellulose paper and water is 7:43; stir in the pulp tank for 4 hours , after stirring evenly, put it into the refining tank for refining for 1 hour to make a uniform mixed slurry. Pass the mixed slurry through the automatic papermaking forming drying line at a constant speed, and precisely control the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com