A damping vibration isolator for power facilities

A technology for power facilities and vibration isolators, which is applied in the direction of non-rotational vibration suppression, can solve the problems of easy tearing and vibration isolator failure, and achieve the effects of simple production, improved energy consumption capacity, and improved damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

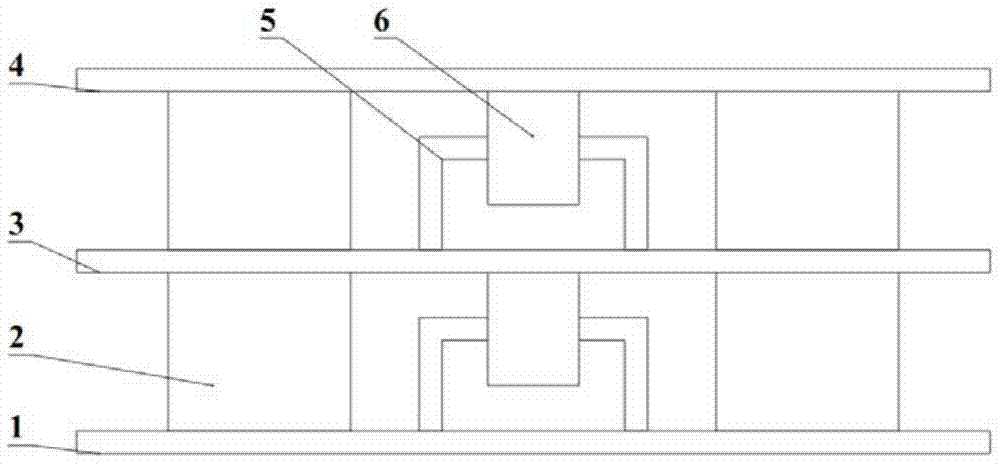

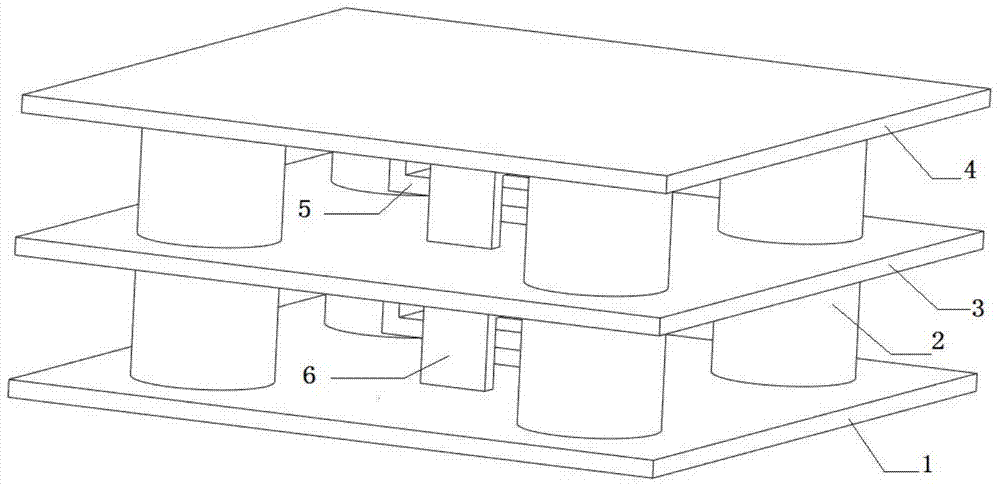

[0041] Such as figure 1 As shown, a damping vibration isolator for power facilities, the vibration isolator includes a top plate 4, a middle plate 3, and a bottom plate 1 arranged coaxially and parallel in the horizontal direction, and a support 2 and a limiter are arranged between every two adjacent plates. pieces.

[0042] Preferably, the support 2 includes a composite layer in which a cylindrical lead alloy core and covered rubber sheets and thin steel plates are arranged alternately.

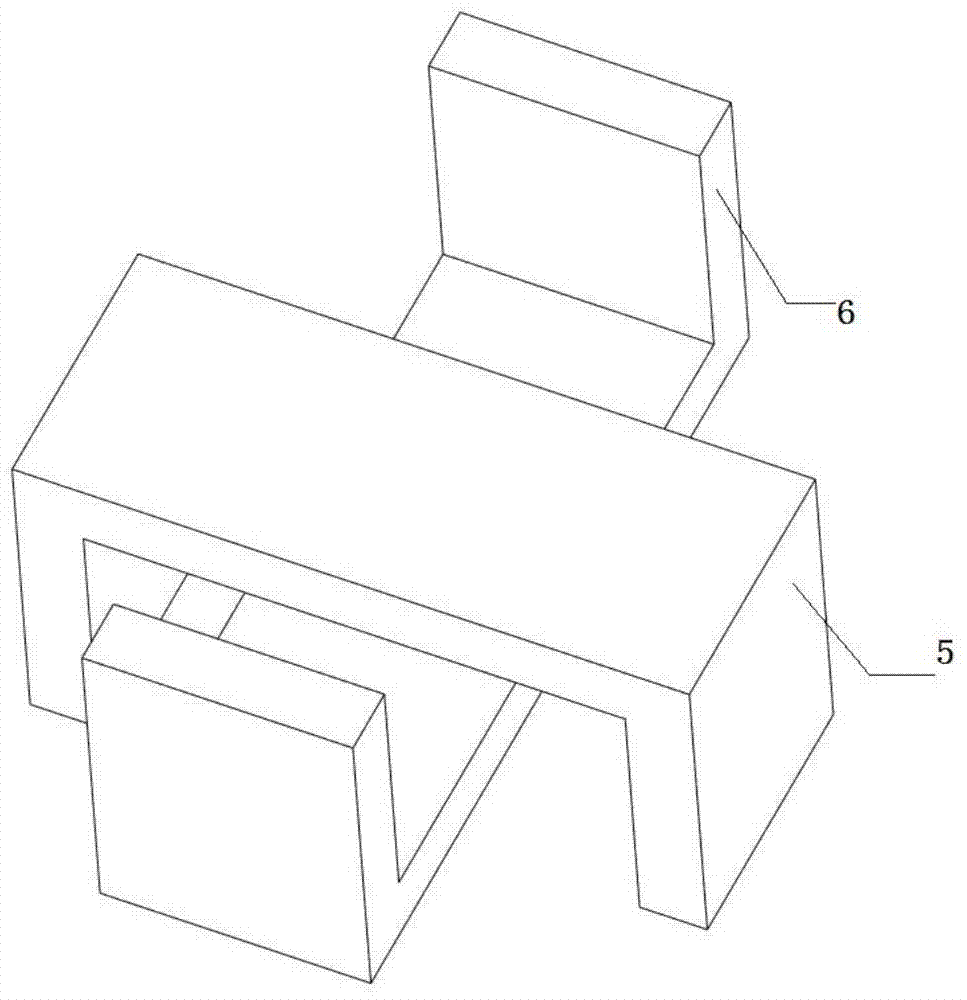

[0043] Preferably, the limiter includes an inverted U-shaped lower limiter 5 and a U-shaped upper limiter 6 respectively correspondingly arranged on the upper and lower surfaces of two adjacent plates where the upper and lower surfaces perpendicularly intersect, and the limiter is arranged inside the support 2 .

[0044] The limit block is made by welding steel plates.

[0045] Preferably, the top plate 4, the middle plate 3, and the bottom plate 1 adopt square steel plates with correspond...

Embodiment 2

[0055] The structure is consistent with Example 1, and the lead alloy core is made of the following components in terms of mass percentage: 0.10% aluminum, 2% antimony, 0.1 calcium, 1% strontium, and the balance is lead and unavoidable impurities.

[0056] Connect the center of support 22 to form a square, and the center of the square is located on the axis of the plate; the distance between the intersection of the axis of support 22 and the plate and the nearest apex of the plate is 1 / 5 of the diagonal length of the plate.

Embodiment 3

[0058] The structure is consistent with Example 1, and the lead alloy core is made of the following components in terms of mass percentage: 0.15% aluminum, 2% antimony, 3% calcium, 1% strontium, and the balance is lead and unavoidable impurities.

[0059] Connect the center of support 22 to form a square, and the center of the square is located on the axis of the plate; the distance between the intersection of the axis of support 22 and the plate and the nearest apex of the plate is 1 / 9 of the diagonal length of the plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com