Closed adiabatic air cooler

An air cooler and heat insulation technology, which is applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of affecting the heat transfer effect of the tube bundle, wasting electric energy and water resources, and unable to adjust the temperature , to improve the heat transfer effect, reduce water consumption, and meet the heat transfer requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

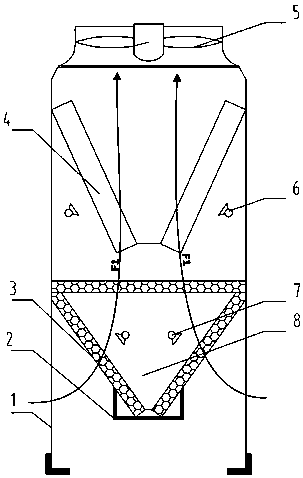

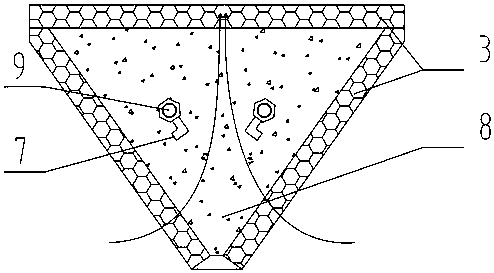

[0026] In the transitional season when the temperature and humidity of the external environment are moderate, the air cooler is in the adiabatic humidifying air mode. At this time, the fan 5 and the atomizing nozzle 7 are in the working state, and the spraying nozzle 6 is in the non-working state. See figure 2 , figure 2 It is a schematic diagram of the adiabatic chamber of the air cooler. The pipe 9 of the atomizing nozzle 7 circulates city tap water for the atomizing nozzle 7 to spray the water. , so that the temperature of the air outlet from the adiabatic chamber is reduced to the wet bulb temperature close to the ambient air. At this time, the low-temperature humid air at the outlet of the adiabatic chamber flushes the heat exchanger tube bundle, which increases the heat exchange temperature difference of the fluid at the heat exchanger and effectively improves the Compared with the spray evaporative cooling mode, the water consumption and the power consumption of the p...

Embodiment 2

[0028] When the temperature and humidity of the external environment are high, the air cooler is in the spray evaporative cooling working mode. At this time, the fan 5 and the spray nozzle 6 are in a working state, the atomizing nozzle 7 is in a non-working state, and the spray nozzle 6 is directed to the fins. The sheet-tube heat exchanger 4 is sprayed with spray water, so that the outer wall of the heat exchanger tube is covered with a water film. The heat is used to cool the circulating fluid in the pipe, and the spray water outside the pipe wall that has not been evaporated in the future flows into the water collection tank. The water in the water collection tank continues to supply water to the spray device through the circulating water pump to reduce water consumption. The spray evaporative cooling mode is suitable for the meteorological conditions of high temperature and high humidity to meet the requirements of heat exchange.

Embodiment 3

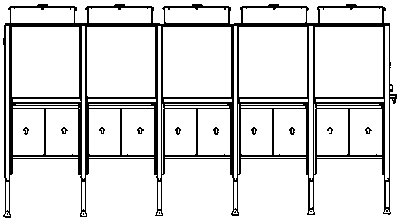

[0030] refer to image 3 , 4, image 3 , 4 is a combination diagram of ten air cooler modules of the present invention. The air cooler of the present invention is a modular device, and the air cooler modules can be combined and used according to different heat exchange requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com