Method of making optical planar waveguide

A production method and optical plane technology, applied in the field of optical waveguides, can solve the problems of small batches, the processing technology of optical plane waveguide plates is not very mature, etc., and achieve the effect of reducing half-wave voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, patent of the present invention is described further:

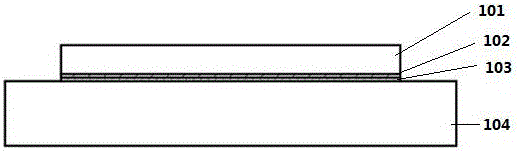

[0013] Such as figure 1 As shown, the side heat dissipation conditions of the waveguide laser microchip are very good, and the heat dissipation of the laser crystal can be greatly improved by bonding without introducing a large stress. For improving the light extraction efficiency of Nd:YVO4, Nd:YAG, Nd:YLF, Yb:YAG and other waveguide lasers. 101 is a laser microchip, 102 and 103 are metal films of the same type (indium film or silver film or gold film), 104 is a substrate, 102 metal film is plated on the side of 101 laser microchip, 103 metal film is plated on 104 substrate . Under the condition of applying uniform pressure between 101 and 104, the two are bonded together by using metal as a bonding medium.

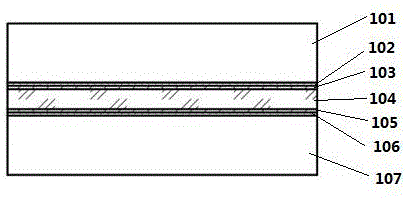

[0014] Such as figure 2 As shown, 101, 107 are substrates; 102, 103, 105, 106 are metal films; 104 is BBO. With this structure, the crystal is calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com