Intelligent control method of steering engine electro-hydraulic loading system

A loading system, intelligent control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the adverse effects of system anti-interference, response speed technical indicators, control accuracy can not meet system requirements, identification information Insufficient accuracy and other problems, to improve the loading accuracy and response speed, and solve the effect of online real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

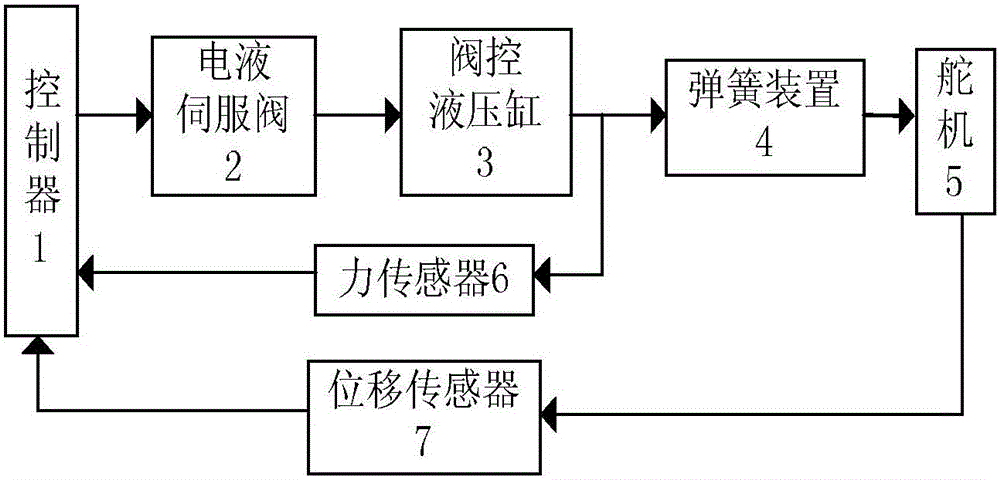

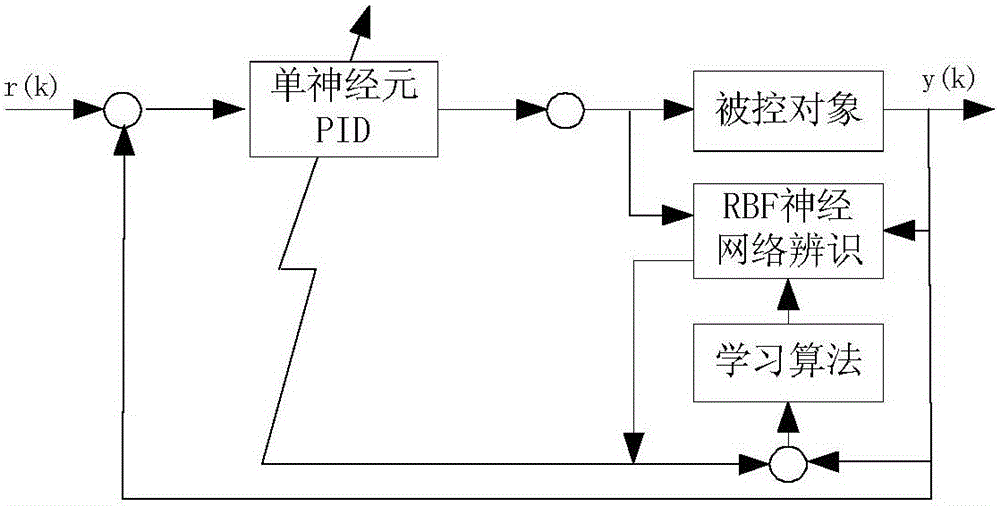

[0022] The intelligent control method of the steering gear electro-hydraulic loading system provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The intelligent control method of the steering gear electro-hydraulic loading system provided by the present invention includes the following steps in order:

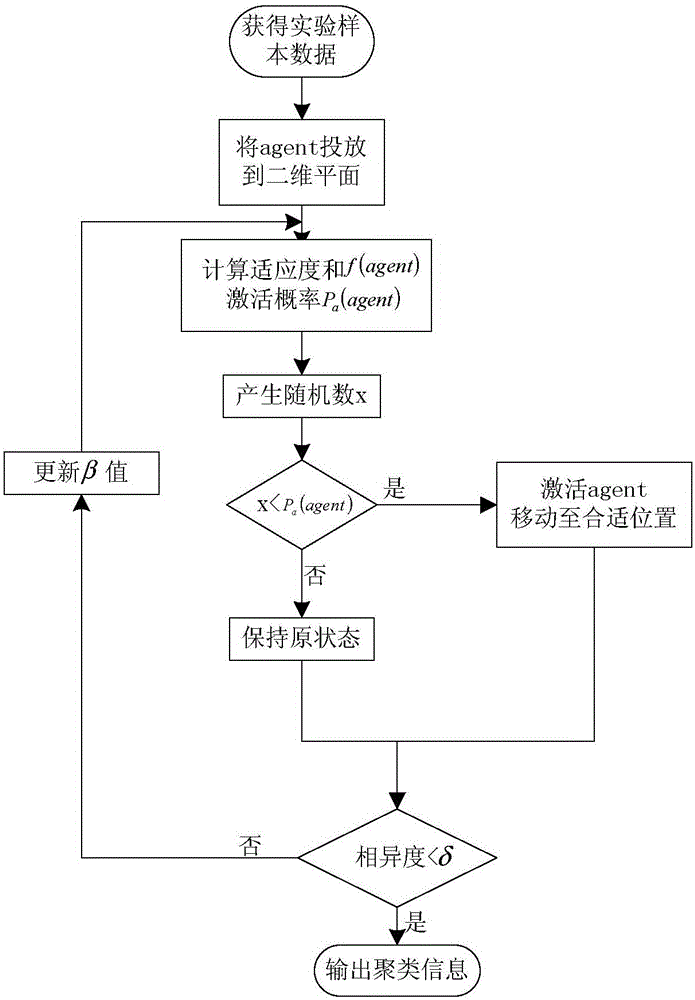

[0024] 1) The controller 1 obtains the clustering information including the number of clusters and the cluster centers by using the ant colony clustering algorithm;

[0025] Such as figure 2 As shown, through a large number of field tests, the input and output experimental sample data of the steering gear electro-hydraulic loading system are obtained, and each artificial ant (agent) is set to represent an experimental sample data, and it is constantly looking for the appropriate location, so that the agent dynamically self-organizes to form clusters.

[0026] In ant colony cluster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com