Connecting structure and connecting method of lithium battery pole lugs and battery shell

A technology of battery casing and connection method, applied in the direction of batteries, structural parts, battery pack components, etc., can solve the problems of connection that cannot be disconnected, cannot be solved, and poor contact, so as to avoid connection uncertainty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

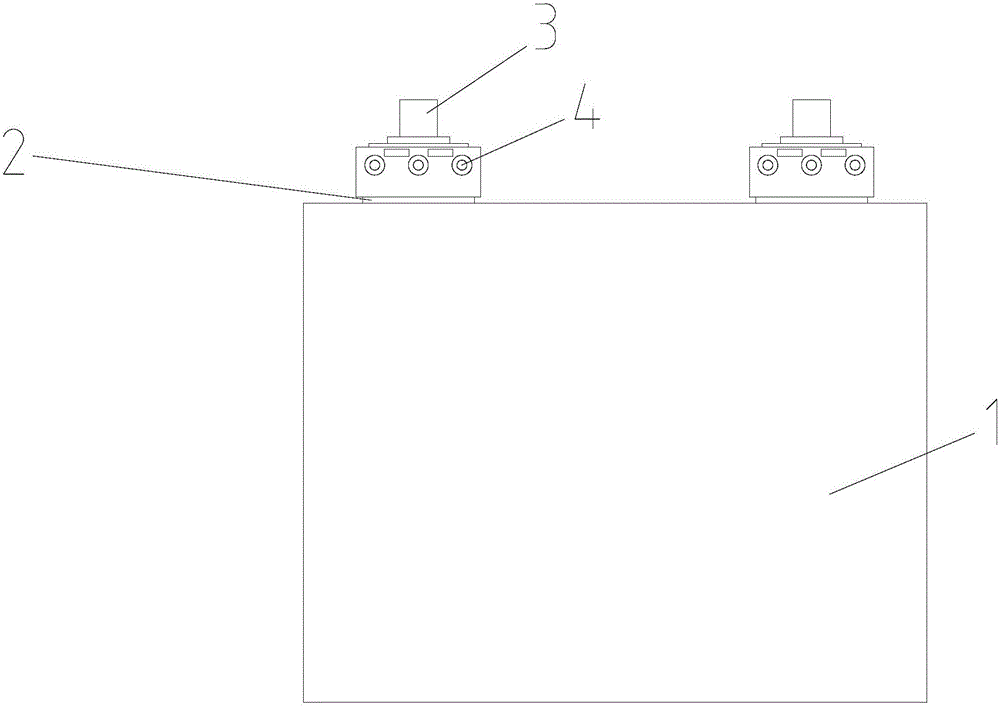

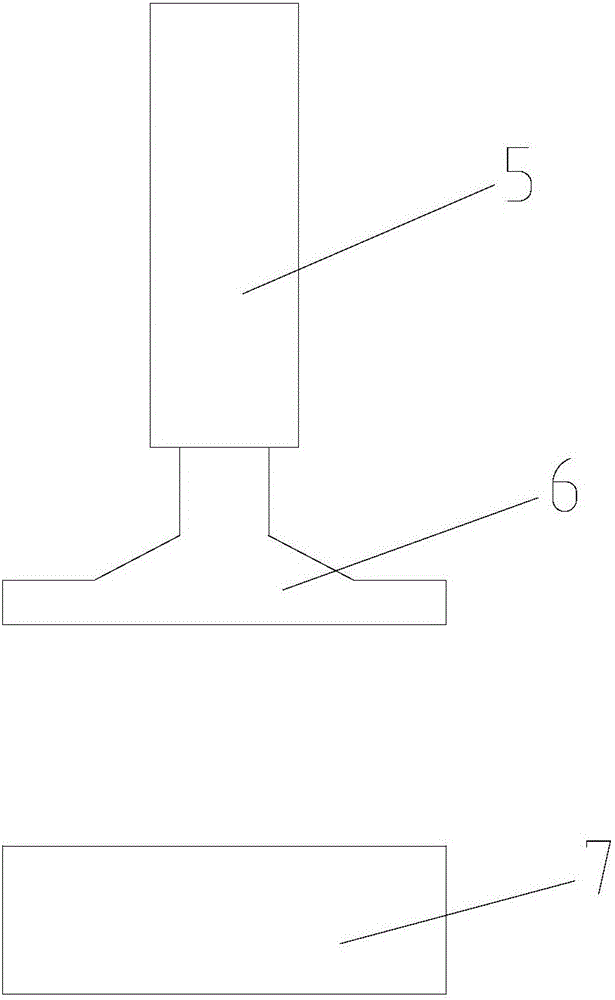

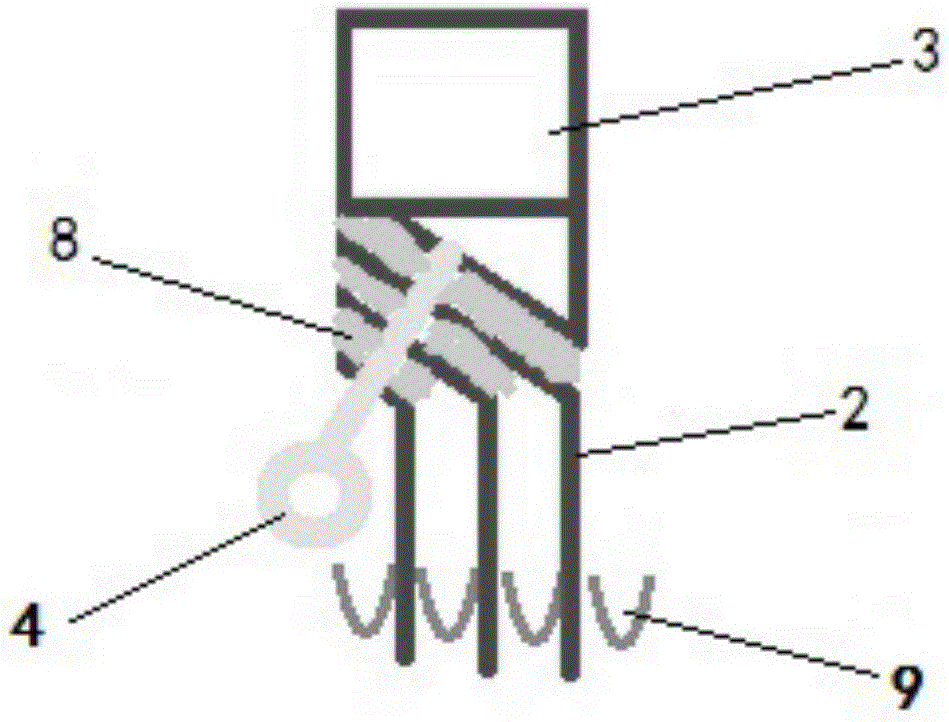

[0023] refer to figure 1 and image 3 As shown, in this embodiment, conductive glue is used to glue and connect the tab 2 provided on the cell body 1 with the pole 3 provided on the battery casing, thereby completing the electrical connection between the tab of the lithium battery and the battery casing, and Ultrasonic welding, laser welding, resistance hot-melt welding, riveting, bolting and other connection methods that have many defects in traditional technology are not used.

[0024] Generally, there are many tabs 2 on the battery core body 1, and these tabs 2 need to be connected to the corresponding poles 3 on the battery case during assembly. Generally, multiple tabs should be connected to one pole. Therefore, in this example, several tabs 2 of the same group are first bonded together with conductive adhesive 8, and then the group of tabs 2 bonded together are bonded and connected to corresponding poles 3 as a whole by using conductive adhesive. Instead of connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com