Baked fat-based confectionery and method for manufacturing same

A manufacturing method and oil-based technology, applied in cocoa, food science, application, etc., can solve problems such as sticky surface, poor taste and appearance, chocolate melting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

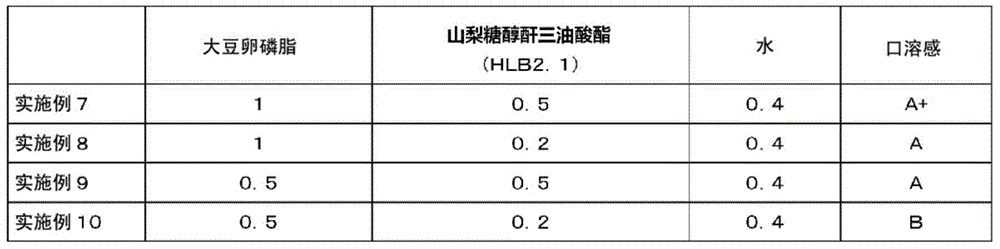

Examples

manufacture example 1

[0050] Using 18 parts by mass of cocoa mass, 40 parts by mass of granulated sugar, 20 parts by mass of whole milk powder, 21 parts by mass of cocoa butter, 0.5 parts by mass of soybean lecithin, and 0.5 parts by mass of flavoring, it was mixed, pulverized, and refined by a conventional method for chocolate manufacturing, A milk chocolate base material having an oil content of 36% by mass was obtained.

Embodiment 1

[0052] 92 parts by mass of the milk chocolate base material obtained in Production Example 1, 7.5 parts by mass of shortening (trade name: MelanoSS, manufactured by FUJIOIL CO., LTD.) and sorbitan trioleate (trade name: Emasol (0-30V, manufactured by KAOCORPORATION) 0.5 parts by mass were mixed to obtain oily confectionery material A for baking.

[0053] The water content of the obtained oil-based confectionery material A for baking was 1.0 mass % with respect to the mass of the whole oil-based confectionery material A for baking.

[0054] The obtained oil-based confectionery base A for baking was adjusted in temperature by a conventional method, then shaped and cooled to solidify, and a roughly cubic oil-based confectionery for baking with a side length of about 1.6 cm and a mass of 4.4 g was obtained.

[0055] The obtained oily dessert was baked at 200° C. for 3 minutes in a hot air oven to obtain the baked oily snack of Example 1. The water content of the obtained oily con...

Embodiment 5

[0067] After tempering the milk chocolate base material obtained in Production Example 1 that does not contain sorbitan fatty acid ester but contains 0.5 parts by mass of soybean lecithin, fill 2.2 g of it into a substantially cubic resin mold with an inner volume of 3.7 ml. . Next, the chocolate base material was expanded using a metal stamper cooled to -20° C. so as to spread over the entire inner wall of the mold. The metal stamper was taken out to obtain a cup-shaped oily confectionery containing the milk chocolate base material in the mold.

[0068] The oily confectionery material A for baking used in Example 1 was temperature-regulated, and 1.6g was filled in the recessed part of the said cup-shaped oily confectionery.

[0069] Furthermore, from above, 1.0 g of the milk chocolate base material obtained in the manufacture example 1 after temperature adjustment was filled in the cup-shaped oily confectionery, and it covered the oily confectionery material A for baking fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com