Fruity soft sweets and preparation method thereof

A soft candy and fruity technology, which is applied in the field of fruity soft candy and its preparation, can solve the problems of insufficient selection, weakened effect of other excipients, easy loss of water, etc., and achieves simple and easy preparation method, promotion of absorption and transformation, and good health value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

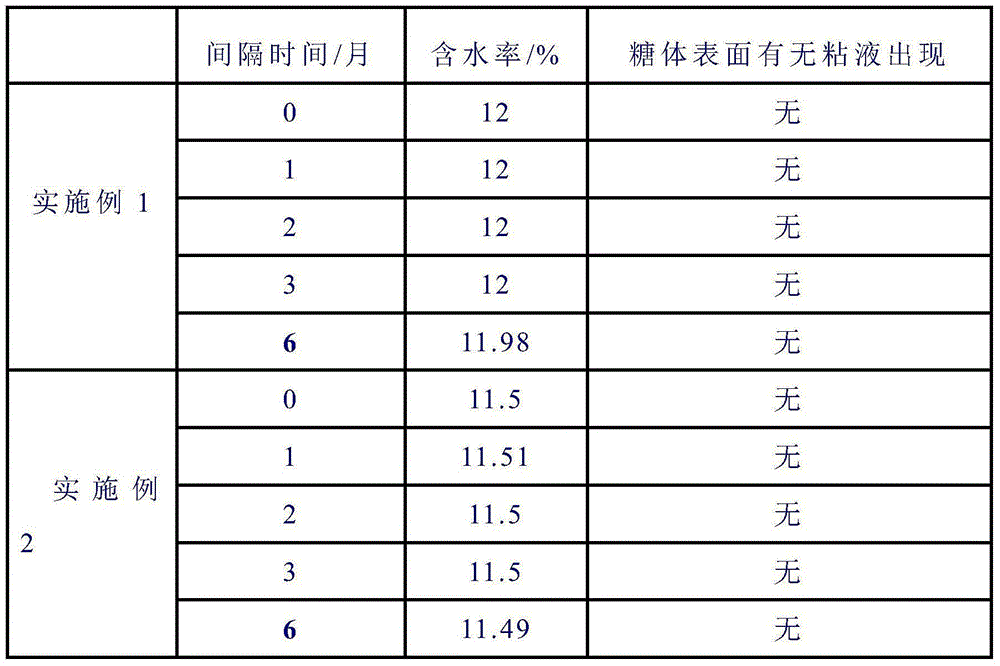

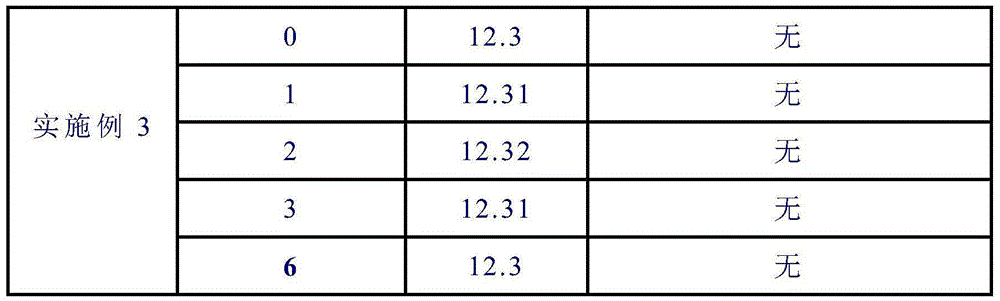

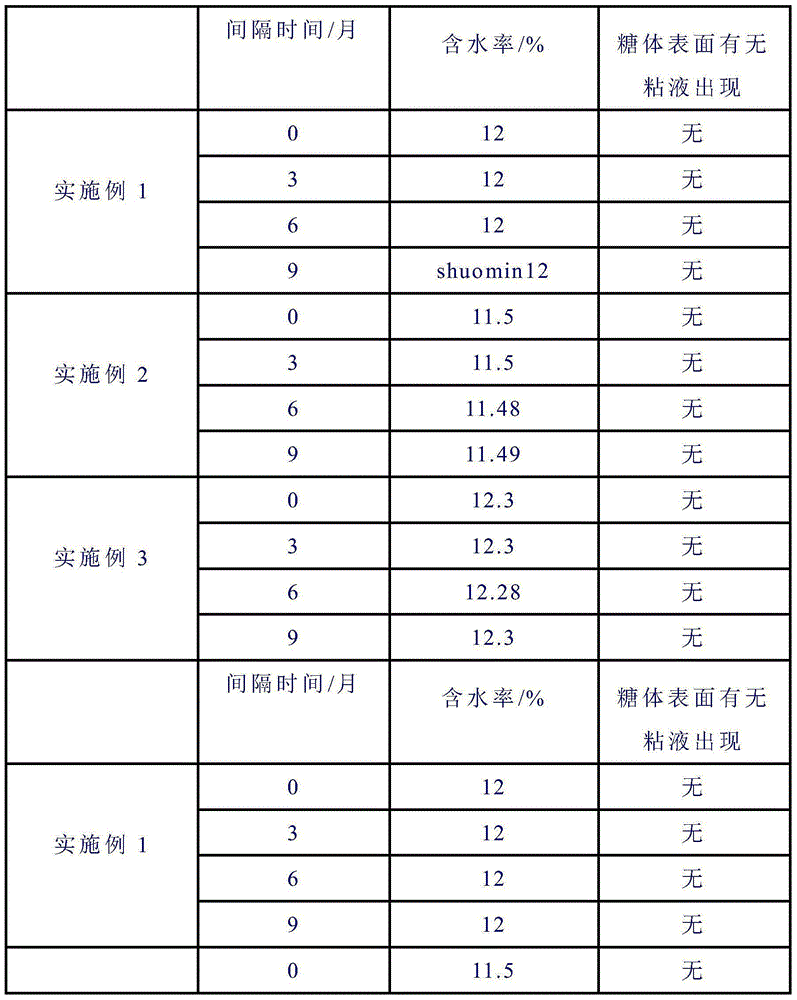

Examples

Embodiment 1

[0025] Fruity soft candy, made of the following components in parts by mass: 21.6 parts of white sugar, 72.3 parts of glucose syrup, 1.9 parts of compound carrageenan, 0.65 parts of citric acid, 0.336 parts of sodium citrate, 3.0 parts of concentrated fruit juice 0.21 parts of edible essence, 0.004 parts of lemon yellow, 30 parts of water.

[0026] The preparation method of described fruity jelly, comprises the steps:

[0027] Step 1: According to the mass ratio, add 1.9 parts of compound carrageenan to 28.5 parts of water and soak for 2 hours, mix 0.65 parts of citric acid and 0.336 parts of sodium citrate evenly, add to 1.5 parts of water, stir and dissolve for later use;

[0028] Step 2: Mix 72.3 parts of glucose syrup and 2 / 3 of the white granulated sugar, heat up and cook, stir continuously during cooking, then add the soaked compound carrageenan obtained in Step 1, heat up to 105°C insulation;

[0029] Step 3: Add 0.004 parts of tartrazine, 3.0 parts of concentrated fr...

Embodiment 2

[0032] Fruity soft candy, made of the following components in parts by mass: 21 parts of white granulated sugar, 72 parts of glucose syrup, 1 part of compound carrageenan, 0.5 part of citric acid, 0.2 part of sodium citrate, 2.9 parts of concentrated fruit juice part, 0.2 part of edible essence, 0.002 part of lemon yellow, and 16.05 part of water.

[0033] The preparation method of described fruity jelly, comprises the steps:

[0034] Step 1: According to the mass ratio, add 1 part of compound carrageenan to 15 parts of water and soak for 1 hour, mix 0.5 part of citric acid and 0.2 part of sodium citrate evenly, add to 1.05 parts of water, stir and dissolve for later use;

[0035] Step 2: Mix 72 parts of glucose syrup and 2 / 3 of the white granulated sugar, heat up and cook, stir continuously during cooking, then add the soaked compound carrageenan obtained in Step 1, heat up to 105°C insulation;

[0036] Step 3: Add 0.002 parts of lemon yellow, 2.9 parts of concentrated frui...

Embodiment 3

[0039] Fruity soft candy, made of the following components in parts by mass: 22 parts of white granulated sugar, 73 parts of glucose syrup, 2 parts of compound carrageenan, 1 part of citric acid, 0.4 part of sodium citrate, 3.2 parts of concentrated fruit juice 0.25 parts of edible essence, 0.005 parts of lemon yellow, 32.1 parts of water.

[0040] The preparation method of described fruity jelly, comprises the steps:

[0041] Step 1: According to the mass ratio, add 2 parts of compound carrageenan to 30 parts of water and soak for 3 hours, mix 1 part of citric acid and 0.4 part of sodium citrate evenly, add to 2.1 parts of water, stir and dissolve for later use;

[0042] Step 2: Mix 73 parts of glucose syrup and 2 / 3 of the white granulated sugar, heat up and cook, stir continuously during cooking, then add the soaked compound carrageenan obtained in Step 1, heat up to 106°C insulation;

[0043] Step 3: Add 0.005 parts of tartrazine, 3.2 parts of concentrated fruit juice, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com