Integrated crushing disposal method of industrial timber wastes

A processing method and integrated technology, applied in grain processing, chemical instruments and methods, solid separation, etc., can solve the problems of limited wood crushing equipment, different shapes of branches, difficult economic transportation, etc., and achieve good results and good quality of finished products , The effect of high crushing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

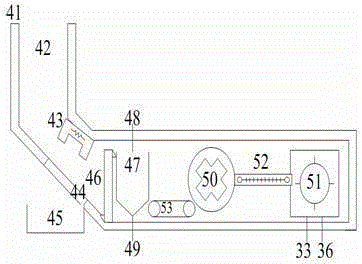

[0019] Such as figure 1 The integrated processing system for industrial wood waste shown includes a housing 41, a wood inlet 42 is provided on the upper left of the housing 41, a first discharge port 44 is provided at the lower left slope of the housing 41, and a first discharge port 44 is provided below the first discharge port 44. Equipped with a material storage box 45; the area inside the shell is divided into two areas, the left area is the pretreatment area, and the right area is the crushing area; the lower end of the wood inlet 42 is connected to the pretreatment area, and the right end of the pretreatment area is connected to the crushing area through a scraper conveyor 52 Area left end; pretreatment area includes high magnetic electromagnet device 43, elevator 46, soaking pool 47, metal water inlet pipe 48, metal outlet pipe 49, conveyor belt 53, hammer mill 50; crushing area includes rotary crusher 51; wherein , industrial wood waste is dropped into the machine by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com