Hot isostatic pressing forming method for homogeneous sheath with gradient gradual change structure at connection interface

A technology of hot isostatic pressing and sheathing, which is applied in the field of advanced manufacturing and manufacturing aerospace, to achieve the effect of shortening the process and cycle, overcoming sudden changes in organization and performance, and overcoming technical bottlenecks that are difficult or impossible to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

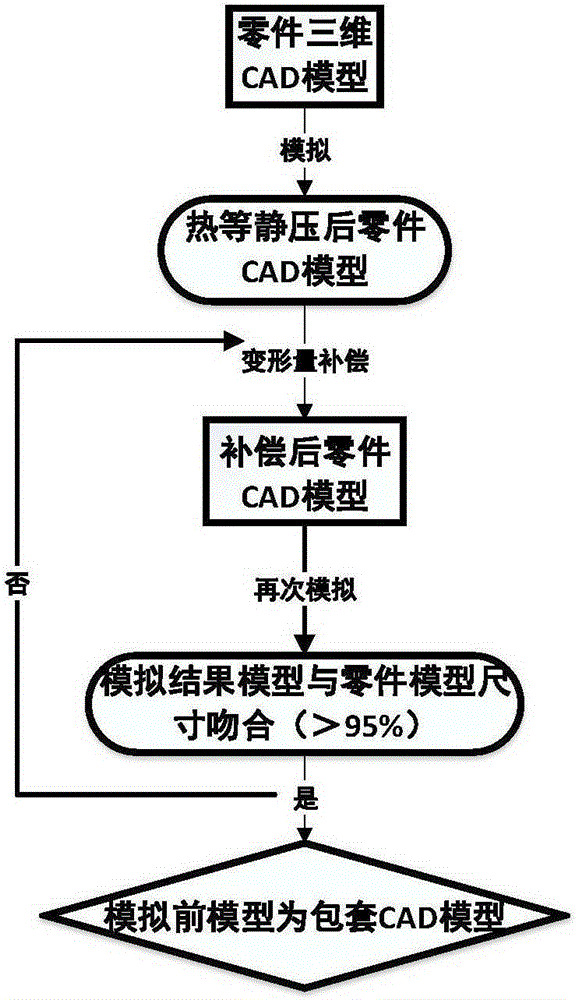

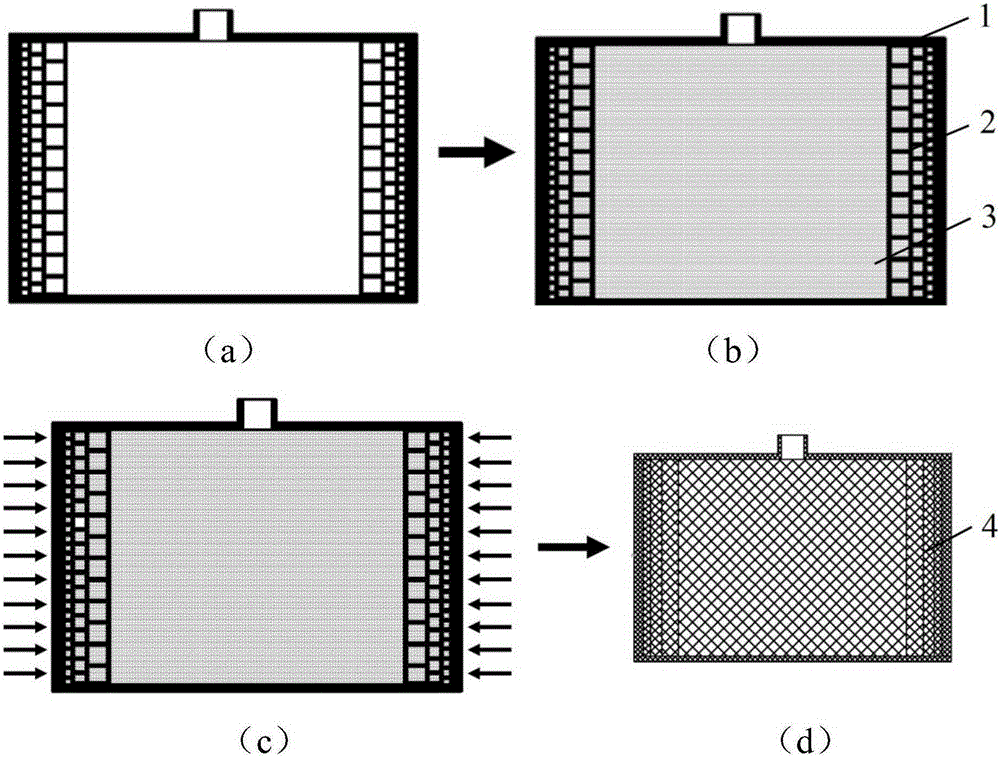

Method used

Image

Examples

example 1

[0047] Using the present invention to manufacture Ni625 turbine disc parts is an example. The manufacture of high-performance aerospace engines is one of the bottlenecks restricting my country's new generation of heavy-duty rockets. As the thrust-to-weight ratio of the new generation of engines continues to increase, its key parts are required to be lighter in weight and have higher mechanical properties. High-performance integral forming technology is required to meet these requirements. Precision casting is currently the mainstream manufacturing technology for key parts such as aerospace engine turbines at home and abroad. However, castings have outstanding problems such as uneven structure, surface quality, internal shrinkage, shrinkage, and inclusions, and it is difficult to meet the high performance and lightweight requirements of the new generation of engines. . For example, in a 460-ton engine turbo pump, the core turbine parts have a linear velocity as high as 300m / s,...

example 2

[0058] Using the present invention to manufacture Ti6Al4V casing parts is an example. With the introduction of new aircraft, higher requirements are put forward for the new generation of engines in terms of working performance indicators. For example, the A320 / B737 and other models with the largest active market share are planning to develop the fifth-generation engine. 0.54-0.55kg / daNh); the noise is 15 decibels lower than the fourth stage of FAR36; the NOx emission is reduced by 40-50%; the maintenance cost is reduced by 15-25%; the service life is extended by 25%. The improvement of these working performances has led to the increasing demand of the engine for high thrust-to-weight ratio, complex structure and high reliability. For example, the tensile strength of the intermediate case when it is in service at 350 ° C is higher than the original index of 500 MPa, which exceeds the existing castings. The performance limit puts forward higher requirements for manufacturing te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com