3D forming method based on outline injection molding

A technology of injection molding and molding method, which is applied in the field of 3D processing, can solve the problems of low interlayer bonding strength and slow speed, and achieve the effect of accelerating injection molding speed and improving interlayer bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

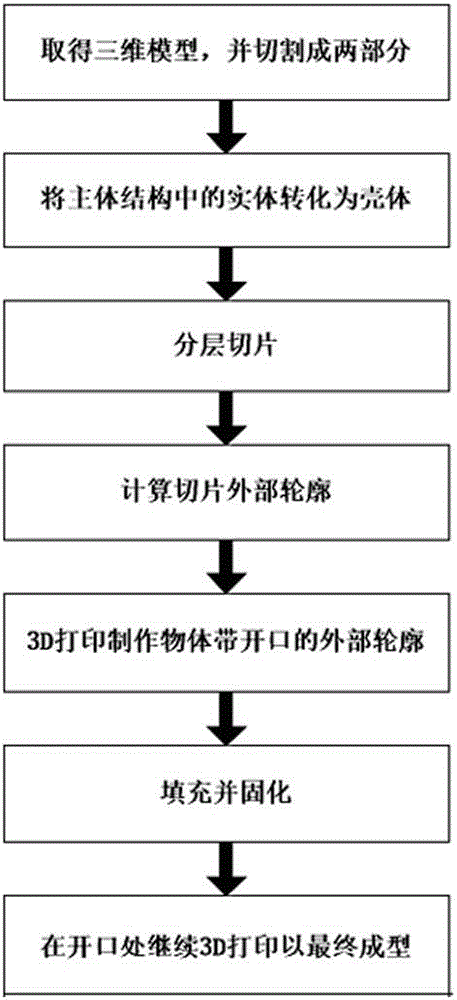

[0018] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0019] see figure 1 , the 3D molding method based on contour injection molding of the present invention, comprises the following steps:

[0020] The first step is to obtain the 3D model and cut it: scan the object to be printed to obtain the point cloud data of the object, use the reverse software to fit the surface and import it into the modeling software to obtain the 3D model of the object, and cut out a small area on the top of the 3D model part, to get the two-part model of the main structure and the top structure; the volume of the main structure in this step depends on the complexity of the top structure. It can ensure the accuracy of printing entities and save the overall printing time.

[0021] The second step is to transform the entity into a shell: shell the main structure in the 3D model, use the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com