Cleaning device, washing type nozzle cleaning system, and digital ink-jet printer

A cleaning nozzle, water-washing technology, applied in printing, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as damage to the service life of the nozzle, affect the printing effect, and easily scratch the surface of the nozzle, so as to reduce the use of Long life, convenient and quick cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

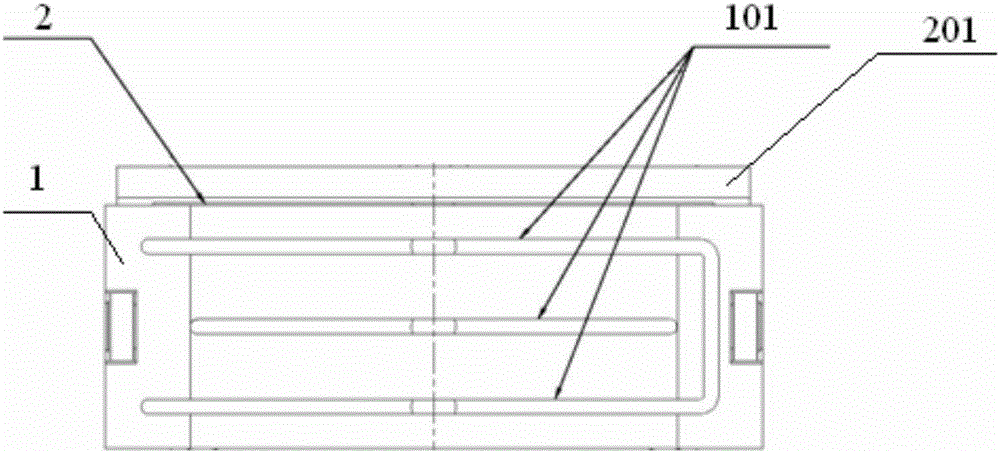

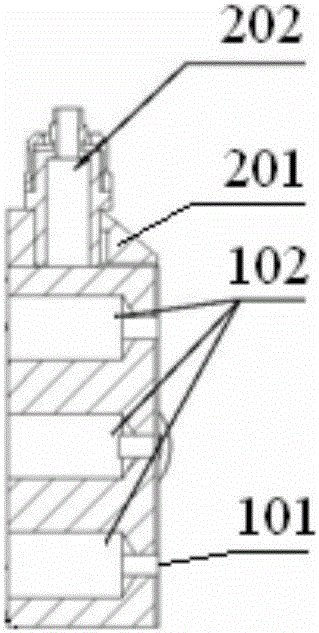

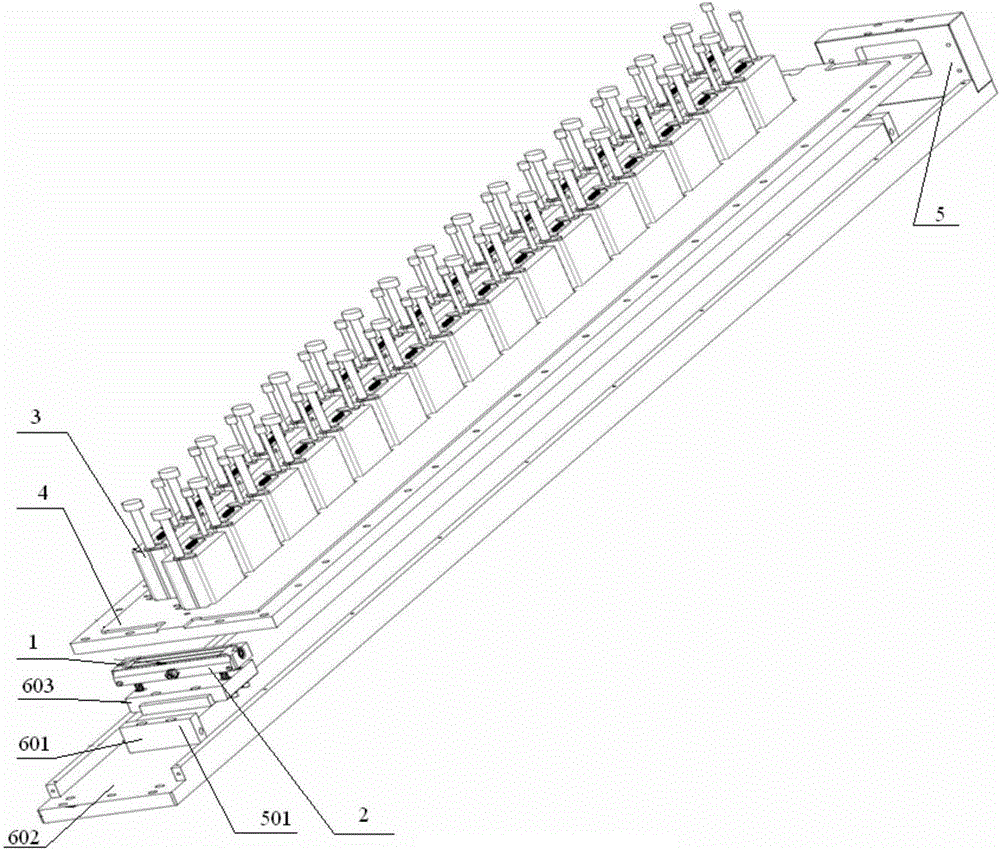

[0045] see Figure 1-Figure 2 , is a structural schematic diagram of the cleaning device provided by the present invention.

[0046] The present invention provides a cleaning device, including a water suction nozzle 1; wherein, a water washing channel 101 and a water inlet hole 102 are opened on the top of the water suction nozzle 1;

[0047] The water washing channel 101 allows the nozzles of the shower head 3 to extend in, so as to clean the nozzles of the shower head 3 . The water inlet hole 102 communicates with the water washing channel 101 , so that cleaning water can be injected through the water inlet hole 102 .

[0048] The cleaning device provided by the present invention, when in use, clean water is input int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com