On-site recovery system for leaking waste liquid

A waste liquid recovery and waste liquid collection technology, applied in liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc., can solve the problems of physical health hazards of maintenance personnel, leakage of leakage, and easy failure of pumps. Avoid leakage of waste liquid, avoid the danger of explosion, and ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

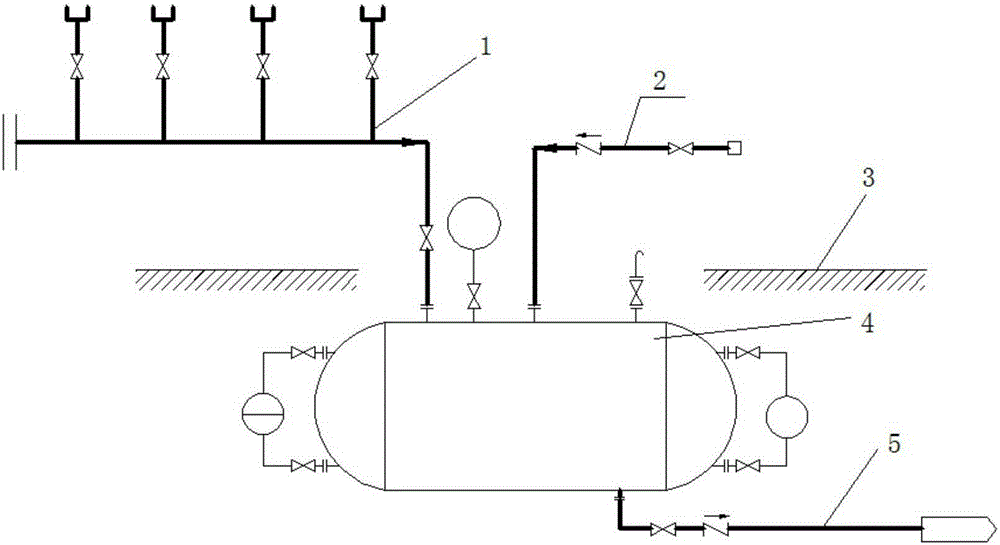

[0026] Such as figure 1 As shown, an on-site waste liquid recovery system includes a waste liquid recovery pipeline 1, a waste liquid collection tank 4, an inert gas pressurized pipeline 2, and a waste liquid delivery pipeline 5, wherein the waste liquid recovery pipeline 1 and the inert gas The pressurized pipelines 2 are all connected to the waste liquid collection tank 4, and the waste liquid delivery pipe 5 is connected to the lower end of the waste liquid collection tank 4. When the waste liquid recovery tank 4 is filled with waste liquid, the inert gas is pressurized and the waste liquid is passed through the waste liquid. The liquid delivery pipeline 5 is transported to the set position.

Embodiment 2

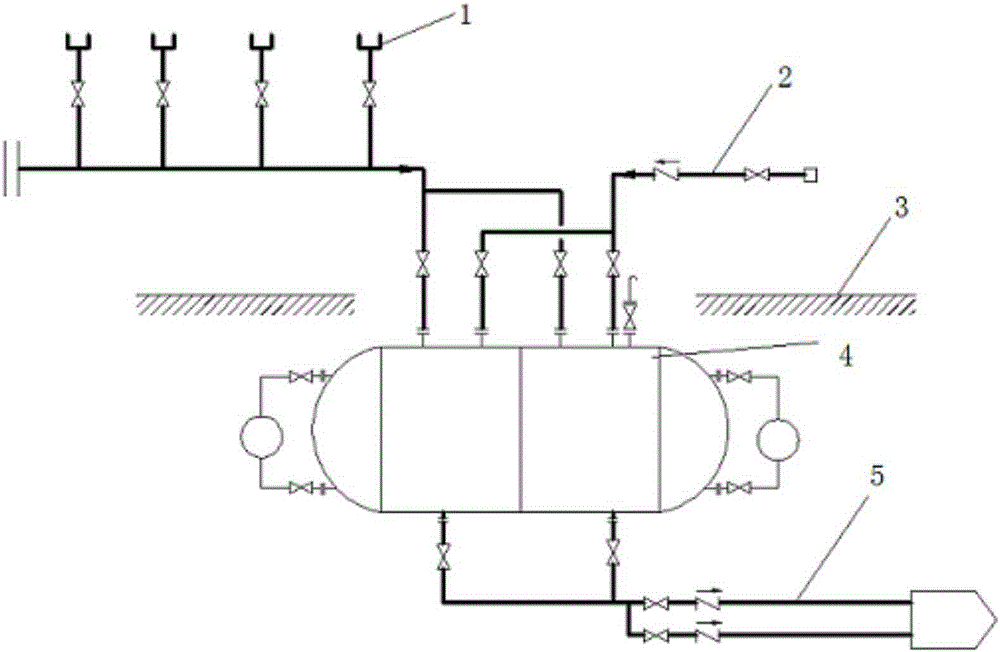

[0028] Such as figure 2 As shown, the waste liquid collection tank 4 can be divided into more than two recovery chambers, and the end of the waste liquid recovery pipeline 1 is divided into several waste liquid recovery branch pipelines, and each waste liquid recovery branch pipeline is provided with a valve; the inert gas The pressurized pipeline 2 is also divided into several inert gas branch pipelines, and each inert gas branch pipeline is provided with a valve, and each recovery chamber is connected with a waste liquid recovery branch pipeline and an inert gas branch pipeline.

[0029] The waste liquid delivery pipeline 5 can also be designed to include a branch section and a main pipeline section, the branch section includes several waste liquid delivery branch pipelines, all waste liquid delivery branch pipelines are connected with the main pipeline section, each waste liquid delivery branch pipeline All are communicated with a recovery chamber, and each waste liquid de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com