Circulating biological selection reactor for livestock and poultry culture sewage treatment

A biological selection and sewage treatment technology, applied in the field of sewage treatment, can solve the problems of high operating cost and complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

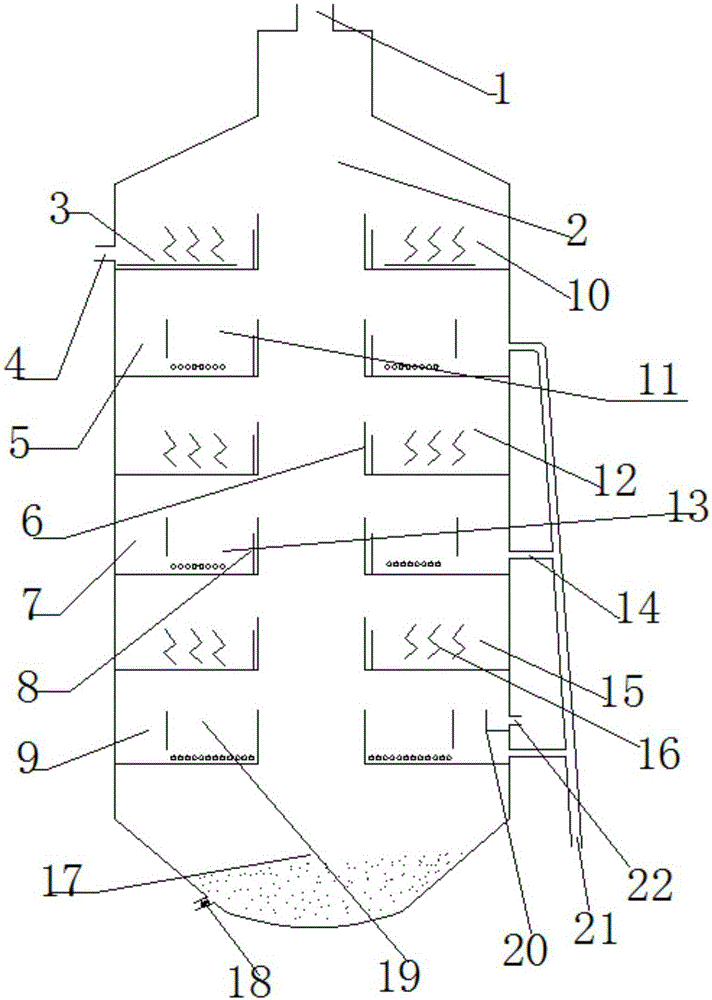

[0025] The livestock and poultry breeding sewage enters the anaerobic first zone (10) in the reactor body (2) through the water inlet (4), the sewage is evenly distributed through the water distribution plate (3), and part of the sludge flows upward from the inclined plate (16 ) falls into the bottom of the tray to realize the separation of mud and water, and the increased part of the sludge overflows the overflow outer plate (6) and directly falls into the sewage collection tank (17) from the central channel, and the anaerobic sewage overflows the overflow inner plate ( 8) Connect the pipeline to the biological selection area (5). After the biological selection, the sewage enters the biological aerobic area (11) from the bottom of the biological selection area (5), aerates for 2 hours, and the water overflows the overflow inner plate (8) It is introduced into the anaerobic second zone (12) through the pipeline for denitrification, and the remaining sludge partly overflows the ...

example 2

[0027]The livestock and poultry breeding sewage enters the anaerobic first zone (10) in the reactor body (2) through the water inlet (4), the sewage is evenly distributed through the water distribution plate (3), and part of the sludge flows upward from the inclined plate (16 ) falls into the bottom of the tray to realize the separation of mud and water, and the increased part of the sludge overflows the overflow outer plate (6) and directly falls into the sewage collection tank (17) from the central channel, and the anaerobic sewage overflows the overflow inner plate ( 8) The pipe is connected to the biological selection area (5). After the biological selection, the sewage enters the biological aerobic area (11) from the bottom of the biological selection area (5) and is aerated for 2.5 hours. The water overflows the overflow The plate (8) is introduced into the second anaerobic zone (12) through the pipeline for denitrification, and the remaining sludge partly overflows the o...

example 3

[0029] The livestock and poultry breeding sewage enters the anaerobic first zone (10) in the reactor body (2) through the water inlet (4), the sewage is evenly distributed through the water distribution plate (3), and part of the sludge flows upward from the inclined plate (16 ) falls into the bottom of the tray to realize the separation of mud and water, and the increased part of the sludge overflows the overflow outer plate (6) and directly falls into the sewage collection tank (17) from the central channel, and the anaerobic sewage overflows the overflow inner plate ( 8) The pipe is connected to the first biological selection area (5). After the biological selection, the sewage enters the first biological aerobic area (11) from the bottom of the first biological selection area (5), and is aerated for 3 hours, and the water overflows the overflow inner plate (8) It is introduced into the anaerobic second zone (12) through the pipeline for denitrification, and the remaining sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com