Reactor with nitrification and denitrification function

A reactor and denitrification technology, applied in the field of reactors, can solve the problems of fixed brackets for installation, easy blockage of fillers, difficult maintenance, etc., and achieve the effects of ensuring effluent water quality, improving utilization rate, and high volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

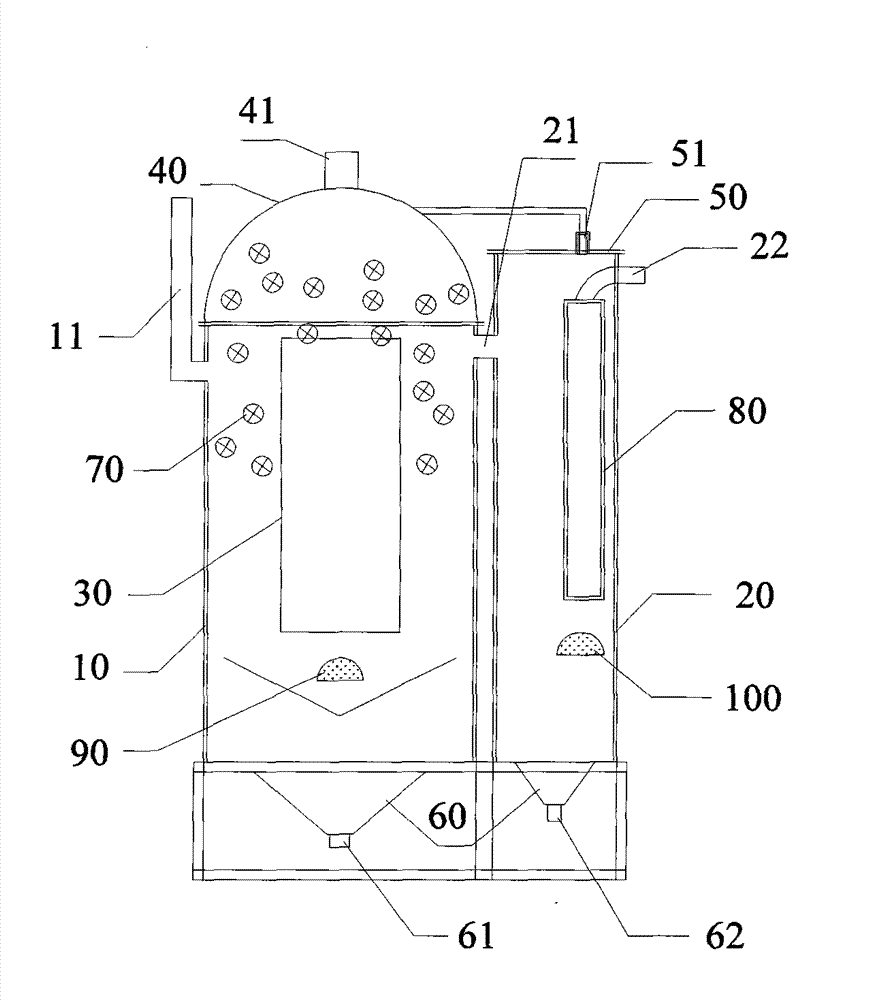

[0026] A reactor with nitrification and denitrification functions, the reactor is an airlift circulating suspended packed bed reactor (Airlift Circulating Floating-carrier Bed, ACFB), its structure is as follows figure 1 As shown: the reactor includes an inner barrel 10, an outer barrel 20, a sewage water inlet 11, a water inlet 21, a water outlet 22, an inner pipe 30, a round head 40, a flat head 50, a mud discharge bucket 60, packing 70, micro Membrane separator 80, aeration device 90 and ozone device 100, the volume load of the reactor is 2kgCOD / m 3 d. The inner barrel 10 is cylindrical, and the ratio of its height to diameter is 5:1. The upper end of the inner barrel 10 is connected to a round head 40, and the round head 40 is provided with a vent 41. The lower end of the inner barrel 10 is connected to an inverted cone-shaped mud discharge Bucket 60, the lower end of the mud discharge bucket 60 is provided with a mud discharge outlet 61, a cylindrical inner tube 30 is arr...

Embodiment 2

[0029] A reactor ACFB with nitrification and denitrification functions, the reactor includes inner barrel, outer barrel, sewage water inlet, water inlet, water outlet, inner pipe, round head, flat head, mud discharge bucket, packing, exposure Gas device, microfiltration membrane separator and ozone device, the volume load of the reactor is 4kgCOD / m 3 d. The inner barrel is cylindrical, and the ratio of its height to diameter is 8:1. The upper end of the inner barrel is connected to a round head, which is provided with a vent hole, and the lower end of the inner barrel is connected to an inverted cone-shaped mud discharge bucket. There is a mud discharge outlet, the cylindrical inner tube is set in the inner barrel, and the volume ratio to the inner barrel is 1.2:1, the bottom of the inner tube is connected with an aeration device, and the filler is suspended filler, which is filled in the cavity outside the inner tube. The diameter is 3cm, the density is 1.0g / cm 3 , the filli...

Embodiment 3

[0031] A reactor ACFB with nitrification and denitrification functions, the reactor includes inner barrel, outer barrel, sewage water inlet, water inlet, water outlet, inner pipe, round head, flat head, mud discharge bucket, packing, exposure Gas device, microfiltration membrane separator and ozone device, the volume load of the reactor is 5kgCOD / m 3 d. The inner barrel is cylindrical, and the ratio of its height to diameter is 10:1. The upper end of the inner barrel is connected to a round head, which is provided with a vent hole, and the lower end of the inner barrel is connected to an inverted cone-shaped mud discharge bucket. There is a mud discharge outlet, the cylindrical inner tube is set in the inner barrel, and the volume ratio to the inner barrel is 1.5:1, the bottom of the inner tube is connected with an aeration device, the filler is suspended filler, filled in the cavity outside the inner tube, the filler The diameter is 5cm, the density is 1.05g / cm 3, the fillin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com