Local cutting device applied to glass production line

A glass production line and cutting device technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as difficulty in obtaining glass with various shapes, inability to meet local cutting requirements, and low competitiveness of glass products, and achieve improvement Cost competitiveness, prevention of accidental injury to workers, and effects of avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

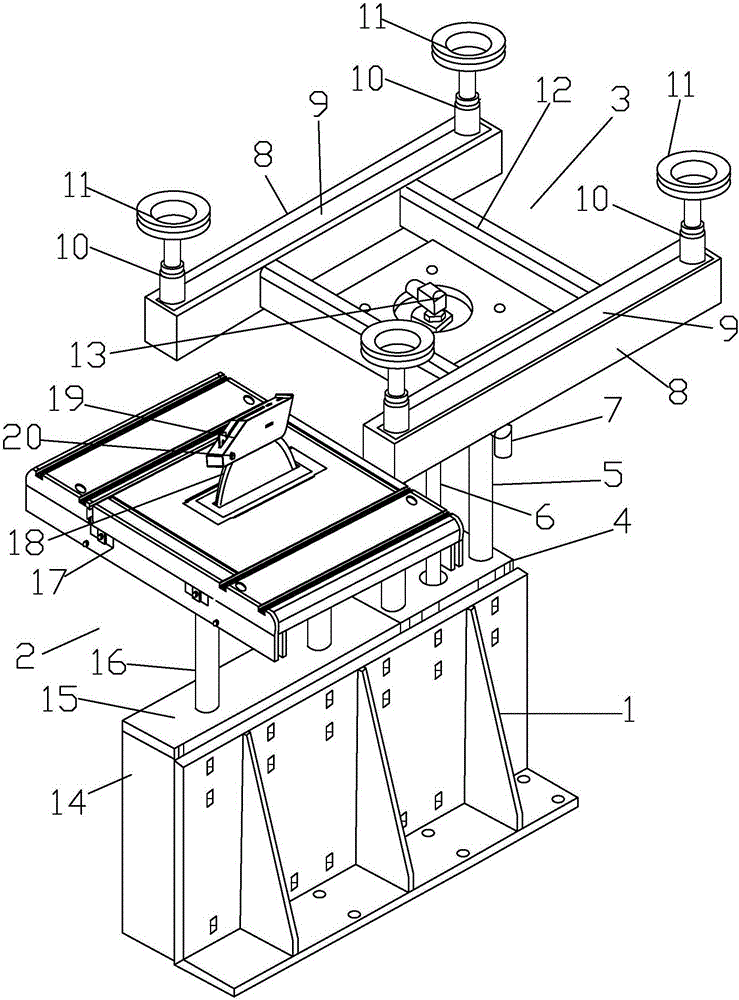

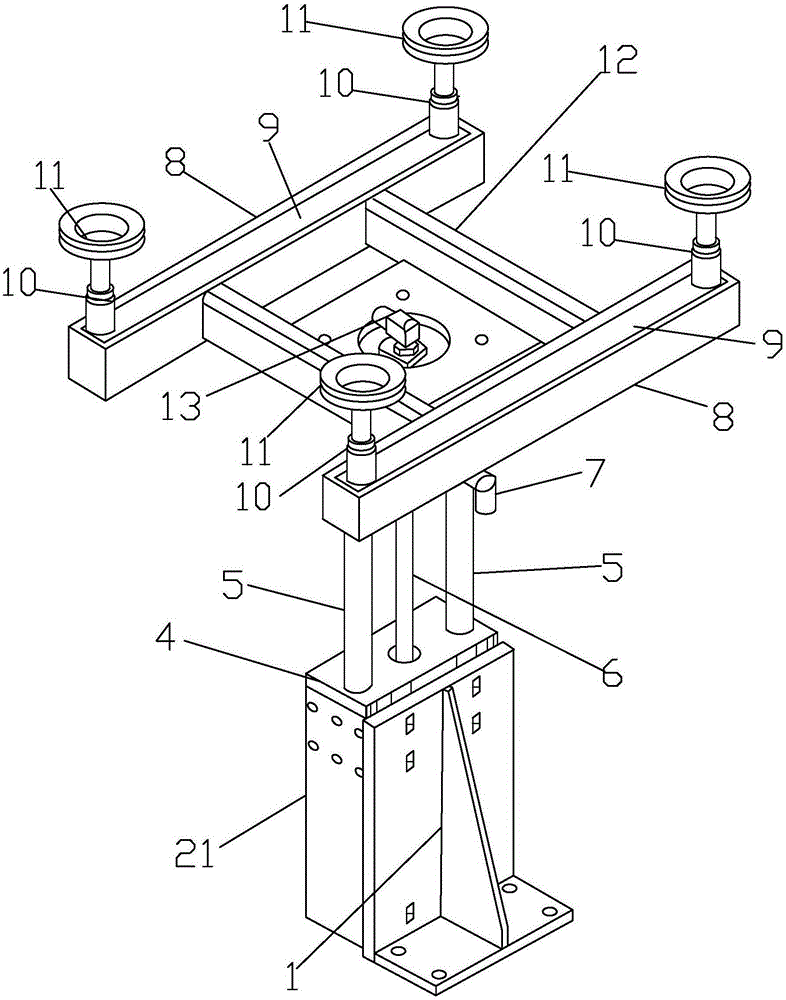

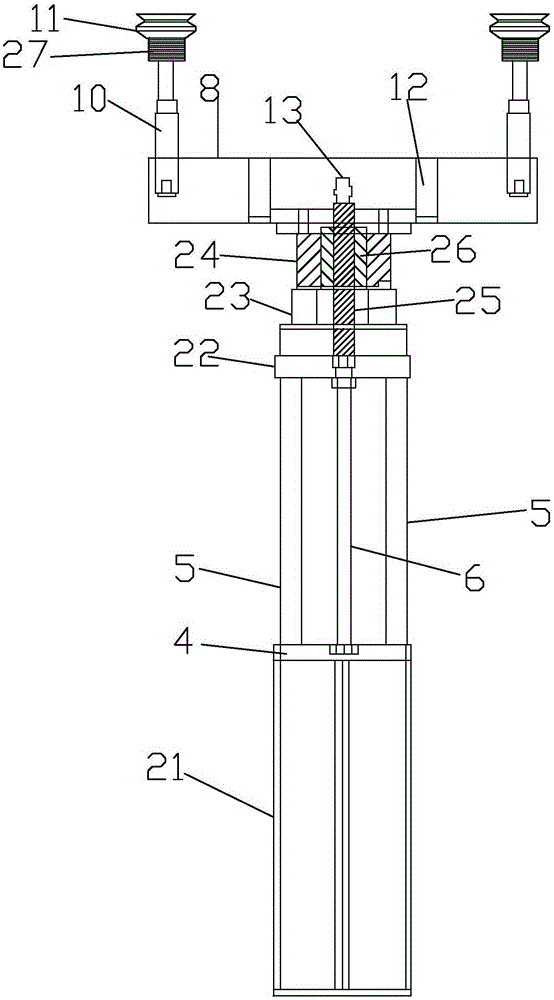

[0031] A partial cutting device applied to a glass production line, which is divided into a cutting mechanism 2 and an operating table 3. A cylinder 8 and a hydraulic cylinder 21 are introduced into the operating table 3. With the help of the air cylinder 8 and hydraulic cylinder 21, the position of the glass can be adjusted arbitrarily, and Cooperate with the cutting mechanism 2 to complete the partial cutting of each position. In actual use, it is found that the partial cutting effect of the present invention is better, and various shapes of glass can be obtained after cutting, so it can be applied in various fields, significantly improve cost competitiveness, and obtain huge economic benefits.

[0032] The cutting mechanism 2 includes a support base 14 and a cutting machine 17. The support base 14 is fixed on the base 1 and fixed by bolts. The support seat 14 is connected with the second guide post plate 15, the second guide post plate 15 is connected with the second guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com