Additive for raw material mixing process of ceramic friction material, and preparation method thereof

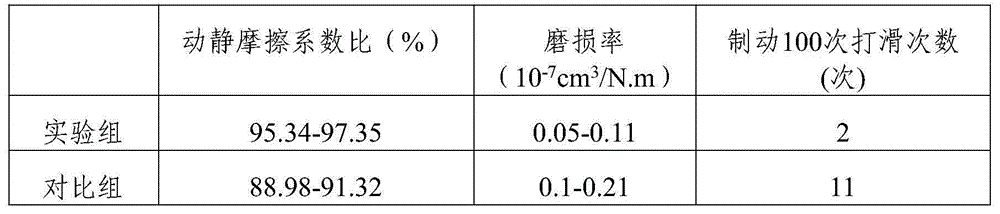

A friction material and mixing process technology, which is applied in the field of additives and preparations of ceramic friction material raw material mixing process, can solve the problems of poor slipping and friction performance, poor toughness, potential safety hazards, etc., and achieve improved friction coefficient, improved surface activity, Prevent slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An additive used in the mixing process of ceramic friction material raw materials. The raw material components are 3kg of ceramic loose cotton, 0.3kg of carbon fiber, 0.1kg of potassium titanate fiber, 1kg of waste oil, 3kg of diesel oil, 1kg of paint, and 1kg of coal powder. Among them, ceramic loose cotton is made by treating 10 parts by mass of clay clinker, 9 parts by mass of alumina powder, 5 parts by mass of silica powder, and 1 part by mass of chrome sand at a temperature of 300 ° C for 20 minutes, and then melting them in an electric furnace It is obtained by spinning it into fibrous silk with a spinning machine, and then collecting cotton with a cotton collector.

[0026] The preparation method of the additive used in the raw material mixing process of the ceramic friction material comprises the following steps:

[0027] (1) Soak the ceramic loose cotton in waste oil, and during the soaking process, add one-third of the coal powder to it, and adjust the tempera...

Embodiment 2

[0032] An additive used in the mixing process of ceramic friction material raw materials. The raw material components are 7kg of ceramic loose cotton, 0.9kg of carbon fiber, 0.7kg of potassium titanate fiber, 3kg of waste oil, 7kg of diesel oil, 3kg of paint, and 7kg of coal powder. Among them, the ceramic loose cotton is made by treating 20 parts by mass of clay clinker, 11 parts by mass of alumina powder, 9 parts by mass of silica powder, and 3 parts by mass of chrome sand at a temperature of 500 ° C for 30 minutes, and then melting them in an electric furnace. It is obtained by spinning it into fibrous silk with a spinning machine, and then collecting cotton with a cotton collector.

[0033]The specific preparation method of the ceramic loose cotton is to mix clay clinker, alumina powder, silica powder and chrome sand, and then treat it at 500°C for 30 minutes, then use ultrasonic treatment for 10 seconds, and then add The clarified lime water accounting for 1% of the mixed...

Embodiment 3

[0041] An additive used in the mixing process of ceramic friction material raw materials, its raw material components by mass are ceramic loose cotton 5kg, carbon fiber 0.6kg, potassium titanate fiber 0.4kg, waste oil 2kg, diesel oil 5kg, paint 2kg, coal powder 3kg, Among them, the ceramic loose cotton is made by treating 15 parts by mass of clay clinker, 10 parts by mass of alumina powder, 7 parts by mass of silica powder, and 2 parts by mass of chrome sand at a temperature of 400 ° C for 25 minutes, and then melting them in an electric furnace. It is obtained by spinning it into fibrous silk with a spinning machine, and then collecting cotton with a cotton collector.

[0042] The specific preparation method of the ceramic loose cotton is to mix clay clinker, alumina powder, silica powder and chrome sand, and then treat it at 400°C for 25 minutes, then use ultrasonic treatment for 20s, and then add The clarified lime water accounting for 3% of the mixed material is sent into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com