Compact anti-erosion reinforced sintered zirconium oxide big brick and production process thereof

A technology of sintered zirconia and production process, which is applied in the field of dense and anti-erosion enhanced sintered zirconia large bricks and its production process, which can solve the problems of cumbersome and complicated process, rising cost of secondary melting and casting zirconia products, and more energy consumption. Achieve the effects of prolonging the cooling time, improving corrosion resistance and cold mechanical strength, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

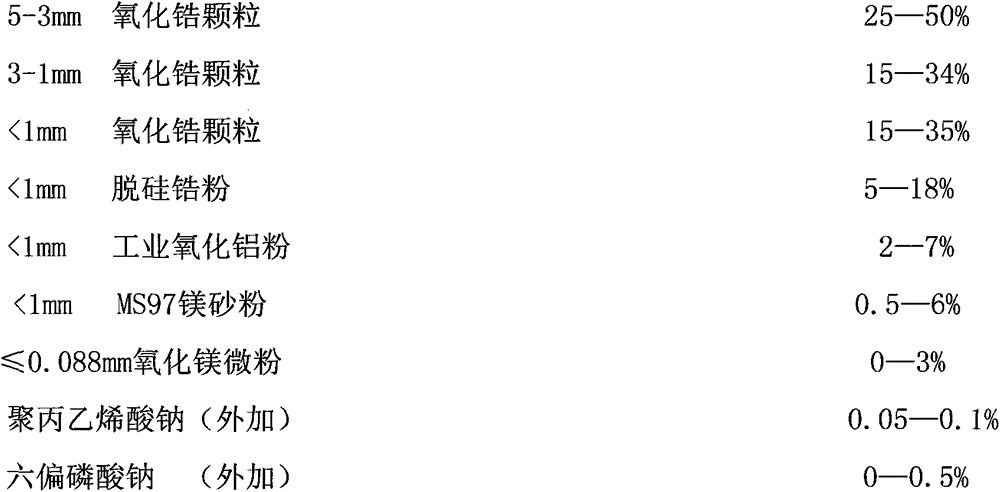

Method used

Image

Examples

Embodiment 1

[0020]

[0021] After weighing each raw material, adding water and stirring, pouring and curing, demolding and drying, the firing time is 68 hours, and the maximum firing temperature is 1630°C. The firing curve is: heating stage 24 hours, heat preservation 6 hours, cooling 38 hours. The temperature of the product out of the kiln is 75°C. After the product is cooled, it is placed in a solution of 25% chromium trichloride hexahydrate for 4 times of vacuum salt immersion, and the conventional performance is tested. And the sintered test bar was processed into a 10×10×70mm sample bar, and the corrosion resistance test was carried out in the aluminosilicate glass melt at 1350°C×48h. In the anti-corrosion test, ordinary sintered zirconia bricks were used as reference samples.

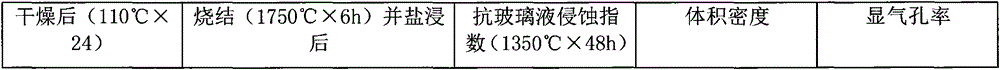

[0022] The test results are as follows:

[0023]

[0024]

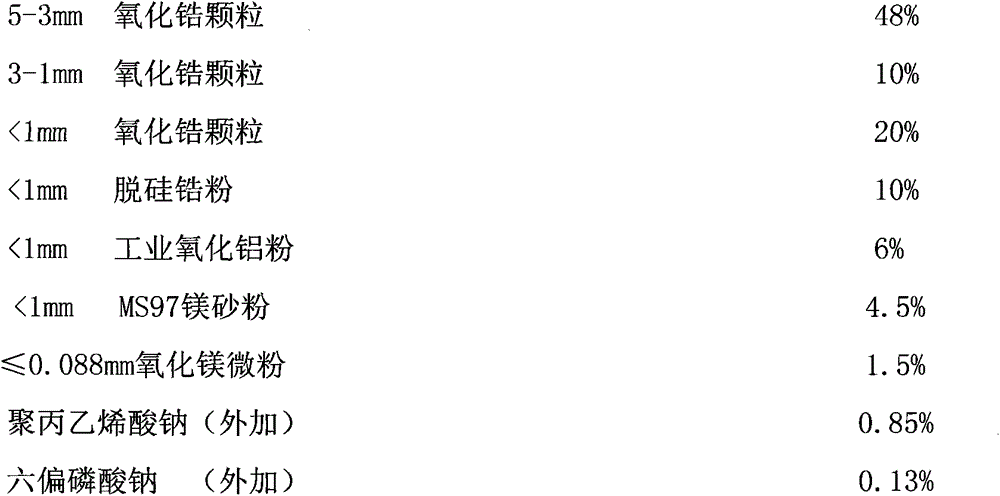

Embodiment 2

[0026]

[0027] After weighing each raw material, adding water and stirring, pouring and curing, demolding and drying, the firing time is 68 hours, and the maximum firing temperature is 1630°C. The firing curve is: heating stage 24 hours, heat preservation 6 hours, cooling 38 hours. The temperature of the product out of the kiln is 75°C. After the product is cooled, put it into a chromium trichloride hexahydrate solution with a concentration of 25% for vacuum salt immersion 3 times to test its general performance. And the sintered test bar was processed into a 10×10×70mm sample bar, and the corrosion resistance test was carried out in aluminosilicate glass melt at 1350°C×48h. In the anti-corrosion test, ordinary sintered zirconia bricks were used as reference samples.

[0028] The test results are as follows:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com