A dense anti-erosion reinforced sintered zirconia large brick and its production process

A technology for sintered zirconia and production process, which is applied in the field of dense, erosion-resistant and enhanced sintered zirconia large bricks and the production process thereof, can solve the problems of more energy consumption, cumbersome and complicated processes, rising cost of secondary fused and cast zirconia products, and the like, Achieve the effect of reducing consumption, prolonging cooling time, improving corrosion resistance and cold mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 5-3mm zirconia particles 48%

[0029] 3-1mm zirconia particles 10%

[0030] <1mm Zirconia particles 20%

[0031] <1mm desiliconized zirconium powder 10%

[0032] <1mm industrial alumina powder 6%

[0033] <1mm MS97 magnesia powder 4.5%

[0034] ≤0.088mm magnesium oxide powder 1.5%

[0035] Sodium polyacrylate plus 0.85%

[0036] Sodium hexametaphosphate plus 0.13%

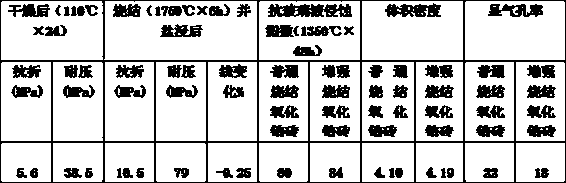

[0037] After weighing each raw material, adding water and stirring, pouring and curing, demoulding and drying, the firing time is 68 hours, and the maximum firing temperature is 1630°C. The firing curve is: heating stage 24 hours, heat preservation 6 hours, cooling 38 hours. The temperature of the product out of the kiln is 75°C. After cooling, the product is placed in a solution of 25% chromium trichloride hexahydrate for 4 times of vacuum salt immersion, and the conventional performance is tested. And the sintered test bar was processed into a 10×10×70mm sample bar, and the corrosion resistance tes...

Embodiment 2

[0041] 5-3mm zirconia particles 40%

[0042] 3-1mm zirconia particles 15%

[0043] <1mm Zirconia particles 25%

[0044] <1mm desiliconized zirconium powder 10%

[0045] <1mm industrial alumina powder 5%

[0046] <1mm MS97 magnesia powder 4.5%

[0047] ≤0.088mm magnesium oxide powder 1.5%

[0048] Sodium polyacrylate plus 0.85%

[0049] Sodium hexametaphosphate plus 0.13%

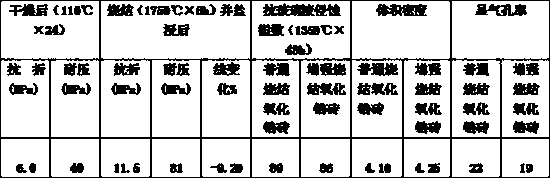

[0050] After weighing each raw material, adding water and stirring, pouring and curing, demoulding and drying, the firing time is 68 hours, and the maximum firing temperature is 1630°C. The firing curve is: heating stage 24 hours, heat preservation 6 hours, cooling 38 hours. The temperature of the product out of the kiln is 75°C. After cooling, the product is placed in a 25% chromium trichloride hexahydrate solution for vacuum salt immersion for 3 times, and the conventional performance is tested. And the sintered test bar was processed into a 10×10×70mm sample bar, and the corrosion resistance test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com