Method for increasing proportion of special grain boundaries in precipitation strengthened austenitic heat-resistance steel

A technology of austenitic heat-resistant steel and special grain boundary, applied in the field of metals and alloys, it can solve the problems of not considering the competitive process of precipitation and recrystallization, the reduction of recrystallization energy, and the poor implementation effect, so as to increase the cumulative potential. The effect of fault and strain storage energy, increasing the content of special grain boundaries, and optimizing high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1. The improved 310 austenitic heat-resistant steel in the hot-rolled state is subjected to grain boundary optimization treatment, and its nominal chemical composition is: 25Cr, 20Ni, 0.1C, 0Mn, 2.0Mo, 0.65Si, 0.2Ti, 0.2Zr, 0.15W, 0.15V, the average grain size of the hot-rolled state is 30μm.

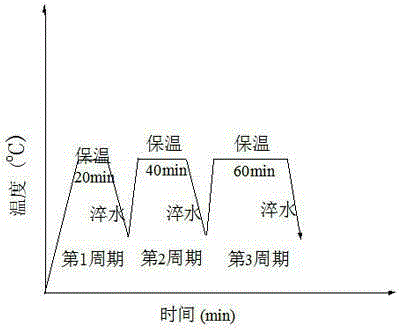

[0024] The first step is to keep warm at 1200°C for 40 minutes, and then carry out rolling deformation at room temperature on a two-roll rolling mill with a deformation amount of 30%, which is completed in two passes; the second step is to hold at 1120°C for 20 minutes and then quench water to cool to room temperature, and then kept at 1120°C for another 40 minutes, quenched and cooled to room temperature; in the third step, spot-polishing and EBSD tests were performed on the treated samples, and analyzed by HKL-Channel5 software. The contents of different grain boundaries are shown in Table 1 As shown, the content of Σ≤29 special grain boundaries reaches 86.24%; its dist...

Embodiment 2

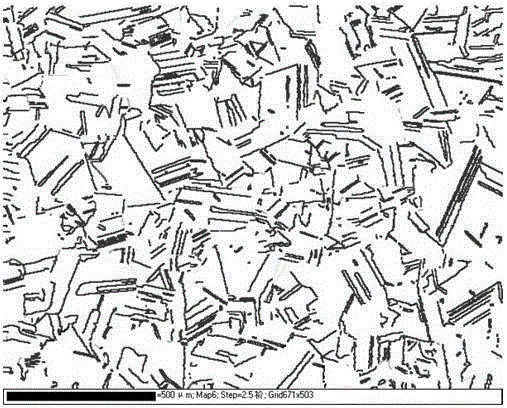

[0025] Example 2 The above methods (1) to (3) were adopted, and after the sample was kept at 1230° C. for 30 minutes for solid solution, it was subjected to 40% room temperature cold rolling. This was followed by 2 cycles of recrystallization annealing at 1150°C. EBSD observation was carried out on the tissue, and the EBSD pictures were analyzed with the help of HKL-Channel5 software. The results are as follows: image 3 shown. The distribution of different special grain boundaries is relatively uniform, and the content of grain boundaries whose content Σ≤29 is 83.15% (see Table 1, different grain boundary contents (number ratio, %) of each example steel).

Embodiment 3

[0026] Example 3 According to the above method, the improved 310 stainless steel was subjected to grain boundary optimization treatment. The nominal chemical composition of the steel is: Fe-25Cr-20Ni-0.2T-0.2Zr-0.1W-0.15V-2.0Mn-0.65Si-0.1C (wt.%), and the sample is solidified at 1250°C for 40 minutes Afterwards, 50% room temperature cold rolling was carried out. Subsequently, one cycle of recrystallization annealing was performed at 1200°C. EBSD observation was carried out on its tissue, and the results were as follows: Figure 4 shown. The uniformity of the microstructure is better, and the sum of the number percentages of different grain boundary types is higher, reaching 86.33%.

[0027] Table 1

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com